Refilling a grease gun or replacing a cartridge has never been simpler

Grease guns are indispensable for applying lubricants to keep mechanical parts moving smoothly. Whether you're a novice or need to replenish your grease supply, reloading the gun is a quick and straightforward process. Whether your grease gun utilizes cartridges or loads directly into the barrel, we'll guide you through each step. Stay tuned, and we'll walk you through the proper procedure for loading and priming your grease gun to ensure it's ready for use.

Essential Information

- Unscrew the nozzle cap from the grease gun and pull out the barrel handle until it locks into place. Remove the old grease cartridge from the barrel.

- Take off the plastic cap from the new grease cartridge and insert that end into the gun's barrel. Peel off the metal tab from the other end of the grease cartridge.

- Reattach the grease gun's nozzle to the barrel and push the handle back in. Activate the nozzle's trigger to prime the grease gun and eliminate any air pockets.

Procedure

Replacing a Grease Cartridge

Twist off the nozzle cap from the grease gun's barrel. Grease guns equipped with cartridges consist of two primary components: the cylindrical barrel and the dispensing nozzle. Orient the grease gun with the nozzle facing upwards. Grasp the nozzle cap firmly and rotate the barrel of the grease gun clockwise to separate the components.

- Set aside the nozzle cap for later use, as it will be needed when reassembling the grease gun.

Pull back the metal handle on the barrel until it locks into position. Identify the T-shaped metal handle situated at the end of the barrel, serving as the plunger rod that pushes against the cartridge to dispense grease. Pull the handle directly outward until it reaches its fully extended position. The handle will either lock into place immediately with a ratchet clip or require rotation to secure it.

- Exercise caution and ensure the handle is securely locked before releasing it, as the spring-loaded rod inside may snap forward rapidly.

Extract the old cartridge from the grease gun. Once the handle is secured, the empty cartridge will be free within the barrel. Tilt the barrel to encourage the cartridge's removal. If the cartridge does not slide out effortlessly, grasp its end and manually extract it. Discard the used grease cartridge appropriately.

- In some grease guns, pulling back on the handle automatically ejects the old grease cartridge.

Remove the plastic cap from the new grease cartridge. Refer to the owner's manual to select the appropriate grease type for lubricating the designated parts. Choose a cartridge matching the size of your grease gun's barrel, typically 14 fluid ounces (410 mL) or 16 fluid ounces (470 mL). Locate the end of the cartridge with the plastic cap and remove it by pulling it straight off.

Insert the open end of the cartridge into the barrel, then remove the metal seal. Use a cloth or rag to wipe off any excess grease from the barrel's end. Insert the open end of the cartridge into the barrel and push it all the way in. Afterwards, remove and dispose of the metal seal attached to the cartridge's exposed end.

- Easily peel off the metal seal or use a sharp object to puncture it for easier removal.

- Inserting the cartridge backwards will prevent proper functioning of the grease gun and inhibit grease dispensing.

Reattach the nozzle and unlock the handle of your grease gun. Align the nozzle with the barrel's end and turn it counterclockwise by two full rotations, leaving it slightly loose. Then, unlock the handle by turning it towards the center or pressing down on the release tab located on the barrel, and slowly push it in. Once the handle is fully pushed in, tighten the nozzle until it's hand-tight.

- Pushing the handle in before fully tightening the nozzle helps purge air from the gun, facilitating easier grease flow.

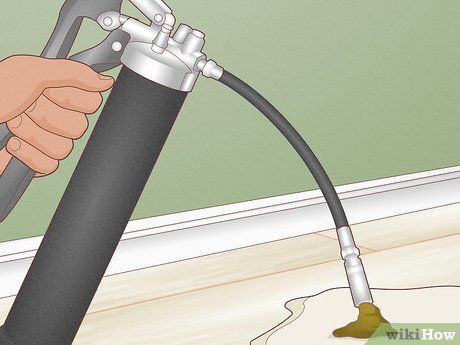

Prime the grease gun until grease emerges from the nozzle. Direct the nozzle hose towards a paper towel or shop cloth to prevent spills. Begin pumping the trigger attached to the nozzle to propel grease through the hose. Continue pumping until grease is visible at the nozzle's end. Wipe off any excess grease with another paper towel or shop cloth to ensure cleanliness before using the grease gun.

- During the initial loading of a grease gun, it may take a minute or two of pumping to expel all air from the system.

- If no grease dispenses after several minutes of priming, unscrew the metal plug atop the nozzle using an allen wrench. Proceed to prime until grease emerges from the plug. Once achieved, wipe off excess grease, reinstall the plug, and resume priming as usual.

Grease Tub Refill

Detach the grease gun head from the barrel. Position the grease gun with the end containing the nozzle and hose facing downwards. Rotate the grease gun barrel counterclockwise to disengage and separate the components. Set aside the nozzle head for later use.

Insert the open end of the gun’s barrel into a grease tub. Refer to the user’s manual to select the appropriate grease for lubricating the intended parts. Push the handle on the barrel all the way in, then submerge the open end of the barrel into the grease container until it's 2 inches (5.1 cm) deep.

- Ensure the barrel’s end remains submerged beneath the grease surface to prevent air pockets, which can hinder the grease gun's efficiency.

Withdraw the handle to fill the grease gun. Gently pull the handle straight out to draw grease into the barrel. While retracting the handle, continue to insert the barrel deeper into the grease container to prevent air entrapment. Upon fully extending the handle, slightly twist it to lock it in place.

- Some grease guns feature clips that automatically lock the handle once fully extended.

Retrieve the barrel and cleanse residual grease with a shop cloth. After securing the handle, lift the open end of the barrel from the grease container. Rotate the barrel to dislodge any clinging grease, then use a shop cloth or paper to wipe off excess grease remnants.

Reassemble the nozzle onto the grease gun and retract the handle. Align the threads of the nozzle cap and barrel, then fasten them together. Loosen the cap by one turn and slowly push the handle back towards the barrel to expel remaining air pockets. Once fully retracted, tighten the nozzle.

Prime the grease gun by operating the nozzle. Position the nozzle on a paper towel or shop cloth. Depress the lever attached to the nozzle to initiate grease flow through the gun. Continue pumping the lever until grease emerges from the nozzle. Wipe off excess grease from the nozzle tip to ensure proper priming for immediate use.

Helpful Hints

Cautionary Notes

- If the handle of the grease gun locks in place when fully extended, avoid releasing the tab until the gun's head and barrel are reattached. The internal piston rod is spring-loaded and may swiftly snap forward.

- Upon removing the metal seal from the end of the new grease cartridge, be mindful of the potential sharp edges on both the cartridge end and the removed metal seal. Exercise caution while handling.

Essential Tools

Replacing a Grease Cartridge

- Grease gun

- Grease cartridge

- Paper towel or shop cloth

Using a Grease Tub

- Grease gun

- Grease tub

- Paper towel or shop cloth