For many individuals, the process of constructing and piloting their own airplane is a deeply gratifying endeavor. The act of building your own aircraft is lawful in the majority of nations and does not necessitate any specialized skills to commence. You can initiate by purchasing a kit online and engaging with aviation communities. After completing the construction, ensure to register your aircraft with your government's aviation authority. Subsequently, you can relish cruising the skies in an aircraft tailored to your preferences. This guide focuses on building full-scale airplanes. For constructing model airplanes, explore alternative resources on Mytour.

Steps

Building the Aircraft

Familiarize yourself with local regulations regarding aircraft construction. In numerous countries, constructing your own airplane is permissible. Typically, you do not require a pilot's license until you are prepared to pilot the aircraft. Simply procure the necessary materials and commence the construction process!

- In the United States, for instance, aircraft regulation is overseen by the Federal Aviation Administration (FAA).

- Adhere to any construction guidelines. For instance, the FAA mandates that you personally construct at least 51% of the aircraft. Demonstrate this through a logbook containing documentation, including photographs and videos of your progress.

Locate a suitable workspace for assembling your aircraft. Many builders opt for their garage, basement, or a dedicated home workshop. Ensure ample space for storing the airplane and its components, and aim to work indoors to maintain a temperature above 50°F (10°C) for optimal conditions.

Select the materials for constructing your airplane, whether wood and fabric, aluminum, or composite materials. Each material offers distinct advantages and price points, so conduct thorough research before committing to a specific kit or design, considering your proficiency in metalworking, woodworking, and sewing.

Procure a building kit online, with prices typically ranging from $6,500 to $15,000 USD. These kits furnish comprehensive plans and materials for constructing the external structure of your aircraft, expediting the assembly process. Explore various kit manufacturers to discover a diverse array of plane models.

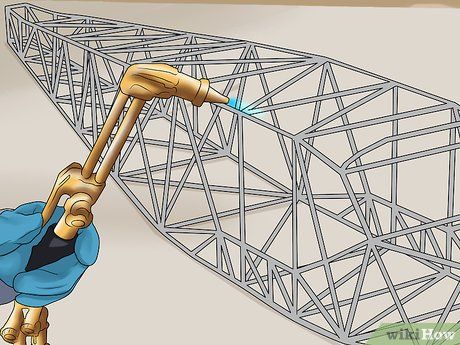

Follow the instructions provided in your kit or plans to assemble the frame of your airplane methodically, starting from the tail and progressing towards the nose. Take it one step at a time until the frame is fully assembled, acquiring necessary skills and tools along the way.

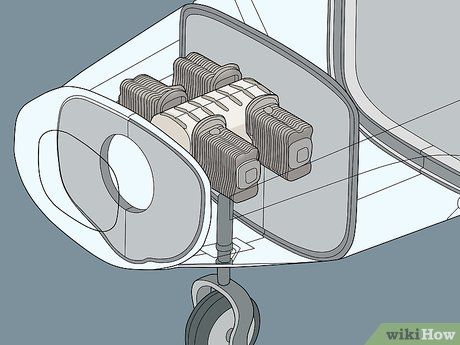

Mount the engine in the nose of the aircraft, positioning it behind the future location of the flight control panel. Utilize wrenches and sockets to secure the engine in place, ensuring proper installation for optimal performance. Consider purchasing engines from reputable manufacturers or repurposing engines from salvage yards.

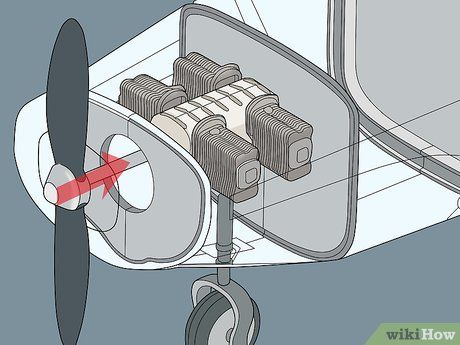

Attach the propeller to the engine's front, ensuring the blades face outward. Tighten bolts using a socket wrench to secure the propeller in place.

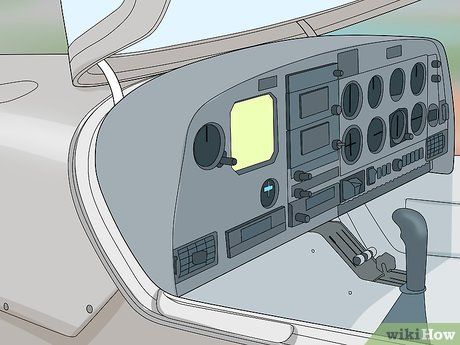

Install the flight panel in the plane's nose, connecting it to the engine via electrical wiring if necessary. Secure the panel with rivets and ensure all instruments function properly.

Customize the interior of your aircraft according to your preferences, ensuring comfort and functionality. Consider ordering or crafting seats if not included in the kit.

Paint your plane with your chosen color scheme using aircraft-grade paints. Apply primer first for better adhesion and protect the aircraft with a finishing material once the paint dries.

Prepare to fly your plane and enjoy the experience of piloting your creation through the skies.

Obtain your pilot’s license during your free time. You'll need it before flying your plane. Start the process early by taking flight classes from a certified school and applying for certification with the FAA or relevant aviation authority.

Transport your plane to an airport for flight. Disassemble parts if possible and reassemble at an airport hangar. Secure transportation by renting a truck or flatbed and ensure all parts are securely strapped down.

Secure storage for your plane, often in airport hangars. Expect annual fees around $700 to $800 for small planes. Hangars offer safety and accessibility.

Complete aircraft registration paperwork through your government’s transportation safety board. Expect a 1 to 2-month registration process. Seek assistance from organizations like the EAA for paperwork.

Undergo the final plane inspection at the airport by a government agent to ensure safety and quality. Receive official certification within 1 to 2 months if your plane passes inspection.

Embark on your maiden test flight. Coordinate the test with the certifying government agency and seek assistance from organizations like the EAA. Complete up to 40 hours of flying to pass the test.

Getting Engaged

Have your work inspected by a certified inspector. Groups like the EAA offer complimentary inspections during your plane's construction. Regular inspections help identify potential issues preventing official certification.

Participate in amateur aviation gatherings and activities. Attend events organized by groups like the Experimental Aircraft Association (EAA), such as the Air Venture in Oshkosh, Wisconsin. Network with fellow builders and learn essential skills.

Experience flights in various aircraft models. Join local aviation chapters and participate in events to connect with other pilots. Gain insights into different aircraft types to inform your building process.

Engage with fellow builders for additional assistance. Attend events and join online building forums to gather insights and potential collaborators.

Helpful Tips

- Your aircraft cannot be utilized for commercial purposes, such as rentals or paid transportation.

- Investing in aircraft insurance can provide financial protection in case of accidents or damage.

- Building your own plane may present challenges, including significant costs and lengthy construction time.

Important Warnings

- Flight regulations vary by region. Ensure you comprehend the regulations before flying.

- Flying an aircraft can pose risks. Obtain proper training and certification before piloting a plane.

- Always verify the accuracy of your construction work. Faulty components can lead to issues later on.

Necessary Materials

- Plane kit or blueprints

- Socket wrench

- Bolts

- Engine

- Propeller

- Flight control panel

- Upholstery

- Paint

- Transportation

- A spacious work area

- A workbench

- A saw (if required)