Nothing ignites the thrill of speed quite like zipping around on a go-kart. Crafting one from scratch or a kit can become an addictive endeavor, a delightful garage project suitable for mechanics of all skill levels. Depending on your tool availability, you can delve into planning an exciting go-kart design, welding together the appropriate chassis, and bringing the machine to life. Refer to Step 1 for further details.

Steps

Project Planning

Develop detailed blueprints for your desired go-kart. Go-karts come in various sizes, shapes, and configurations. These DIY vehicles welcome any design elements you wish to incorporate. The fundamental components include a chassis, a basic engine, and a steering/braking mechanism.

- Let your creativity flow while planning the project, and create intricate diagrams to ensure you procure sufficient materials for completion. Seek inspiration from existing go-karts and glean insights from experienced kart builders.

- Alternatively, you can discover schematics and designs online for a multitude of models, allowing you to leverage existing plans. Utilize a template and customize it according to your preferences.

- For precise chassis dimensions, visit the CIK FIA website: http://www.cikfia.com/fileadmin/content/REGULATIONS/Technical/Technical%20Drawings/2017/Drawing_1.pdf

Determine the appropriate size for your go-kart. Choose the size based on the driver's age and build, ensuring precise planning and measurements to accommodate the required materials. Karts come in three sizes, measured from the center of the kingpin to the middle of the rear axle:

- Baby kart: Ages 5-8, Frame size: 700 to 900 mm

- Cadet kart: Ages 8-12, Frame size: 900 mm to 1010 mm

- Full size kart: Ages 12 and up, Frame size 1040 mm

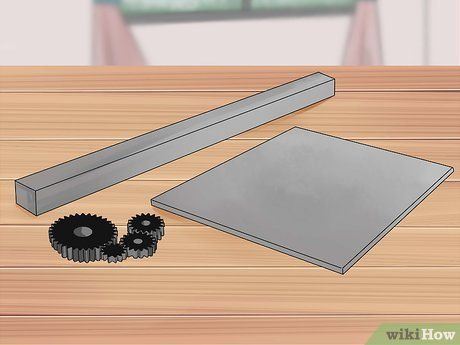

Collect your materials. If budget is tight, explore scrapyards for cost-effective parts or salvage components from old riding lawnmowers or discarded go-karts found at yard sales. Seek spare parts or used 4-cycle engines in the 10 to 15 horsepower range, with horizontal shaft and a drive clutch assembly from lawn mower repair services. Required materials include:

- For the chassis:

- 30 feet (9.2 m) of 1-inch (2.5 cm) square tubing

- 6 feet (1.8 m) of 0.75-inch (2 cm) round steel bar stock

- 6 feet (1.8 m) of 0.5-inch (1.5 cm) bar stock

- 3/16-inch (0.5 cm) thick steel plate larger than the engine

- Plywood or metal (for seat and floorboards)

- Seat

- For the engine:

- Engine (consider an old lawnmower engine)

- Chain that fits the sprocket

- Bolts, washers

- Gas tank

- For the drive train:

- Wheels

- Steering wheel

- Gear and handbrake

- Driveshaft

- Bearings

- Steering shaft

- Brake pedal

- Throttle/go pedal

Secure a welder. Without welding experience, hiring a welder is essential for this project. The chassis, a crucial component, requires sturdy construction to ensure safety during operation and house the engine securely. Proper welding techniques are vital to prevent weak, brittle, or surface-level welds that could compromise the kart's integrity.

- If you lack welding experience, start with smaller projects before attempting a go-kart build.

Explore go-kart kit options. If welding and designing your own kart don't appeal to you, consider purchasing a no-weld kit. These kits come with detailed instructions and schematics, allowing for assembly with basic tools without the hassle of designing and sourcing materials separately.

- Available for around $550, these kits offer the satisfaction of assembling your own go-kart without the complexities of design and material procurement.

Constructing the Chassis and Steering Column

Trim the metal tubing. Cut the tubing to the required lengths based on your design or blueprints.

- Typically, the front end will have a camber angle, narrower than the rear, allowing space for wheel movement and chassis twist. Install a King Pin at the front corners for easy twist.

- For ease, mark the floor or work area with sidewalk chalk to avoid repeated measurements. You can even sketch out the design on the ground and lay the tubing accordingly.

Create a jig for your kart (optional). A jig, a flat metal piece with clamp slots, aids in holding down tubes for precise welding!

Weld the frame based on your blueprint. Elevate the frame with concrete blocks, ensuring sturdy connection points and a secure chassis capable of bearing your weight and the engine's weight. Use gussets for added strength at corners.

Construct the front stub axles. Build the axle using a straight 0.75-inch (2 cm) steel rod and attach two bushings to the frame. Secure the assembly with washers and cotter pins through the axle.

- Mount the front stubs for easy turning and attach the King Pin to the steering arm. Ensure at least a 110-degree angle on the front wheels.

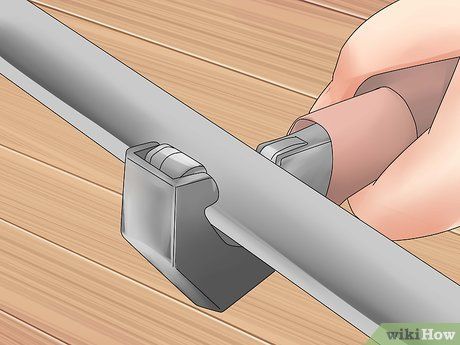

Mount the rear axle and wheel assembly. Assemble an axle carrier with a bearing bracket for the rear axle, welding it to the frame while allowing free rotation. Secure a steel plate onto the chassis and fasten the pressure plate outside with high-tensile bolts and lock nuts to compress the bearing.

- Alternatively, you can purchase pre-made assemblies, often referred to as 'Pillar Bearing Units.'

Construct your seat using plywood and attach it securely to the frame. Drill holes in the plywood and insert T nuts for bolting the seat onto the frame. Cover the plywood with 2' high-density foam, then wrap it with marine vinyl. Secure the vinyl by stapling it to the underside or back of the plywood. Alternatively, consider salvaging a used go-kart seat or a suitable car seat from a junkyard to save costs. Ensure sufficient space for steering, engine, and other controls.

Mounting the Engine and Steering Column

Fit the engine mount. Weld a 3/16-inch (0.5 cm) thick steel plate to the rear frame to mount the engine. Position the engine on the plate, marking the holes for mounting bolts to align the engine pulley with the axle drive pulley. Attach the drive pulley to the axle before mounting it in the bushings, ensuring alignment with the engine pulley.

Assemble the steering linkage. Utilize 0.5-inch (1.5 cm) steel rod for linkages and 0.75-inch (2 cm) for axles. For 90-degree bends in the 0.75-inch (2 cm) rod, use a torch to heat the steel. Include adjustable links for steering alignment to ensure proper caster and camber: front-wheel vertical and steering tilt.

Mount the wheels and brakes. Opt for small racing wheels for optimal acceleration and control. Attach them to the axles with hubs and focus on brake installation for safety.

- For brakes, affix a disc to the rear axle and a caliper assembly to the chassis for a professional-grade system. Salvage assemblies from discarded motorbikes for ease of use and appropriate sizing.

- Incorporate a foot-operated brake pedal, leaving steering as the primary manual control.

Connect the throttle cable to the hand throttle. Depending on your expertise and the type of engine, you might opt for a foot pedal or stick to a traditional hand throttle like a lawnmower.

Verify your brakes and suspension system prior to test-driving. Even at low speeds, ensure no axle slippage on your first run. Inspect welds, brakes, and engine mountings before taking it for a spin.

Tips

-

Save the extras for last; prioritize mechanical components first.

-

The kart includes an accelerator, which can be added using a simple throttle cable assembly from a discarded push mower or a more complex foot-operated gas pedal.

-

Consult a go-kart manual for assistance and driving/tuning advice.

Warnings

- This vehicle is not street legal and should never be driven on public roads under any circumstances!

- Due to its simple design and lack of advanced engineering, it's advised to avoid using a high gear ratio or large engine. Speeds exceeding 10–15 mph (16–24 km/h) may result in component failure due to insufficient engineering.

- Always wear protective gear such as helmets and pads when operating go-karts.

- Prior to racing, thoroughly test the go-kart to ensure all components are secure and functioning properly to prevent detachment or failure during use.

- Adult supervision (age 18+) is required for the construction of the go-kart. While children can assist in gathering tools, they should not assemble parts or handle any equipment.