A knife sheath is indispensable for knife aficionados. It ensures secure and effortless handling and transportation of your knife while also boasting an impressive appearance when crafted skillfully. Among the widely used materials for crafting knife sheaths is Kydex, a rigid thermoplastic material that can be shaped into specific forms when heated. While you have the option to purchase a Kydex sheath, you can also create a durable, customized sheath that will safeguard your knife for years to come.

Steps

Molding Your Kydex Sheath

Determine the required amount of Kydex to encase your knife. Fold a piece of Kydex over the knife blade to create the sheath from a single piece. Outline the blade's shape on the Kydex using a pencil, adding 1 inch (2.5 cm) to the perimeter. While this measurement need not be exact, it's advisable to err on the side of caution and opt for a larger sheath size.

- Having a slightly oversized sheath allows for trimming down later if necessary. Conversely, if the sheath is too small, you won't be able to increase its size by adding more Kydex.

- Ensure that the Kydex sheath does not cover the knife's hilt to facilitate easy removal of the knife from the sheath.

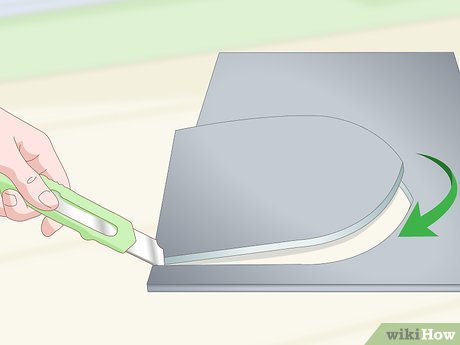

Cut the Kydex to create a single piece covering the entire knife. After removing the knife, use a utility knife to cut along the traced outline on the Kydex.

- While using two Kydex pieces is an option, using a single large piece is simpler.

Bake your sheath in the oven at 275 °F (135 °C) for 5 minutes. This process makes the sheath flexible, allowing for a custom fit. Remember to wear oven mitts when handling the hot sheath. Avoid overheating to prevent melting; monitor the Kydex closely during baking.

- For toaster ovens, set the temperature to 325 °F (163 °C) and bake for approximately 5 minutes.

- The Kydex should reach a leather-like consistency.

Shape the warm sheath around the knife promptly. Within 15 seconds of removing it from the oven, mold the Kydex around the knife. Quickly fold the Kydex over the knife to form the sheath. In case of misalignment, reheat the Kydex for flexibility and restart the process.

- If positioning errors occur, reheating the Kydex provides flexibility for adjustments.

Place the sheath in a foam press to mold it around the knife. The foam press compresses the Kydex, forming a holster around the knife. Line the press with a cotton sheet before inserting the Kydex sheath with the knife. Allow it to set for about 10 minutes before removal, ensuring the Kydex cools adequately.

- The cotton sheet prevents sticking and knife movement within the press.

- Ensure the Kydex is sufficiently solid before proceeding. If not, extend the pressing time by 5 minutes and recheck.

- Foam presses are available for purchase online or at home improvement stores.

Adding Final Touches to Your Sheath

Mark 0.25 in (0.64 cm) circles to indicate rivet placement. Place these circles along the open edge of the Kydex to secure the blade within the sheath. Ensure the circles are evenly spaced, approximately 0.5 inches (1.3 cm) apart, leaving about 1 inch (2.5 cm) of space between the rivet holes and the knife inside the sheath.

- Consider using a pencil for darker sheaths and a colored pencil for lighter ones.

Utilize a drill to create 0.25 in (0.64 cm) holes in the sheath. Verify that the marked rivet locations will securely hold the knife in place while allowing easy removal. Drill holes corresponding to each mark, ensuring not to obstruct the area where the knife will be inserted.

- Confirm that the blade fits in the sheath after punching in the rivets.

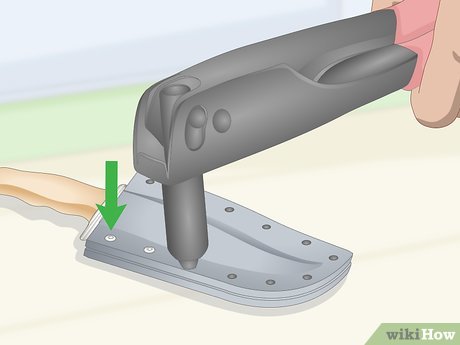

Secure the rivets using a rivet punch. Employ a hand-held or machine punch for this task. Insert the rivet through the hole and use the punch to attach it securely. Punch rivets in a manner that prevents Kydex splitting, working from top to bottom on each side.

- For left-handed individuals, position the knife handle facing left; for right-handed individuals, position it facing right.

- Begin with the topmost rivet and progress downwards, ensuring uniformity on both sides.

Trim excess Kydex from the sheath. After riveting, use a utility knife to cut along the pencil outline, removing surplus material. Avoid cutting until riveting is complete to prevent insufficient space for rivet insertion.

- Retain excess Kydex for future projects if desired.

Refine the sheath surface and edges with fine grit sandpaper. Opt for 360- to 600-grit sandpaper for a polished finish. Sand in gentle, circular motions to smoothen the sheath and achieve a professional appearance. Use masking tape inside the sheath to shield the blade from sand particles.

- Sanding also prepares the sheath for potential painting in the future.

Use WD-40 to wipe off sand and pencil residue. Apply WD-40 onto a cloth and clean the entire sheath to remove any dust, dirt, sand, and pencil marks, giving it a polished appearance.

- Ensure thorough cleaning by wiping all parts of the sheath evenly and giving it multiple passes for a pristine finish!

Completion.

Pointers

Necessary Materials

- Kydex sheet

- Foam press

- Sandpaper

- Utility knife

- Oven or toaster

- WD-40

- Cloth

- Oven mitts

- Rivets and rivet punch

- Drill

- Cotton sheet

- Masking tape