A safety manual serves as a comprehensive compendium of guidelines, protocols, and directives crafted to ensure the secure operation of equipment, substances, and edibles, alongside fostering a secure work environment. Should you be engaged in professional endeavors that involve the utilization of said elements, a safety manual becomes imperative. Moreover, it becomes indispensable in scenarios necessitating employee administration of first aid, CPR, or the execution of safety protocols such as fire drills and evacuations. An adeptly crafted safety manual facilitates alignment between management and staff regarding responsibilities and safety measures, thereby enhancing organizational safety. Though initially daunting, meticulous planning guarantees the efficacy of your safety manual.

Steps

Content

Compile a Comprehensive Inventory and Assign Safety Responsibilities - Enumerate all tools, materials, and safety duties to construct a robust safety plan. This inventory not only informs manual content but also ensures critical aspects are not overlooked. Tailor manuals to specific business areas; for instance, chemical handling, manufacturing machinery, or other pertinent domains. Collaborate with department heads for comprehensive list compilation.

- For instance, chemical-centric companies necessitate sections on storage, handling, and transportation protocols.

- Manufacturing entities might require sections encompassing heavy machinery, hand tools, safety eyewear, etc.

- Engage departmental leaders to contribute to list development.

Familiarize Yourself with Industry Standards. Entities like the International Organization for Standardization (ISO) establish benchmarks for various domains such as risk management and food safety. These benchmarks serve as foundational resources for crafting safety manuals tailored to specific industry requirements. Accessible online or through direct contact with these organizations.

- ISO and analogous bodies furnish comprehensive directives covering production standards, food safety, and other specialized areas.

Adhere to Local Regulations. Consult city and state guidelines to ensure compliance. Regulatory bodies like the Occupational Safety and Health Administration (OSHA) may mandate safety manuals for specific practices and stipulate essential coverage. Reach out to local authorities for clarification and access to pertinent regulations.

- Non-compliance with these regulations, including the absence of mandated manuals, may result in legal repercussions, including lawsuits and potential criminal charges.

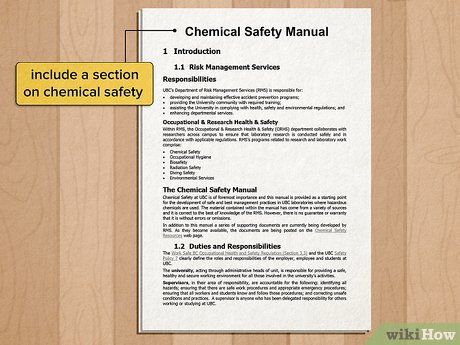

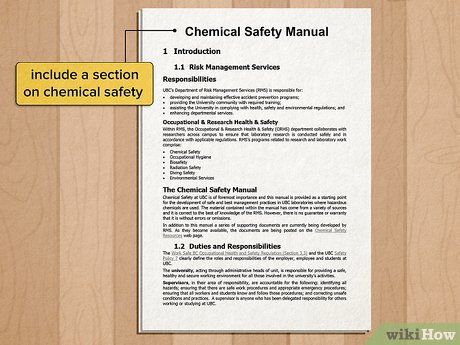

Address Chemical Safety Protocols. Precision in chemical usage is paramount. Manuals should encompass storage, handling, usage, and transportation guidelines. Tailor sections to each aspect, ensuring comprehensive coverage.

- For laboratory settings, meticulous chemical labeling and temperature control are imperative. Manuals should delineate corresponding protocols.

- Incorporate transportation guidelines for intra-facility and inter-facility transfers, if applicable.

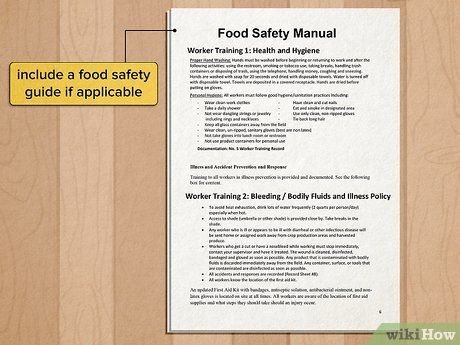

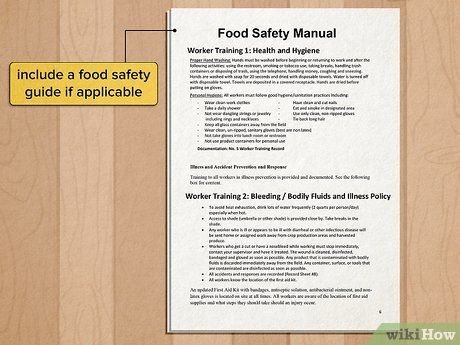

Integrate Food Safety Measures. Robust manuals are indispensable for food-related enterprises. Emphasize food preparation, storage, and handling protocols.

- Include temperature guidelines and expiry date charts as essential components.

- Provide safety instructions for utilizing professional-grade equipment like mixers and stoves.

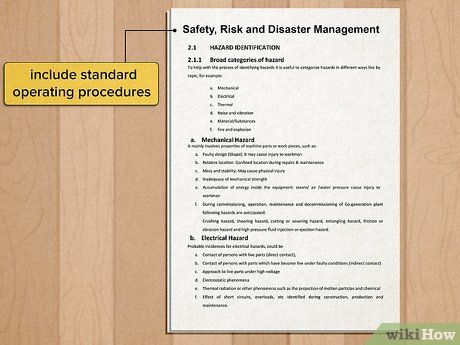

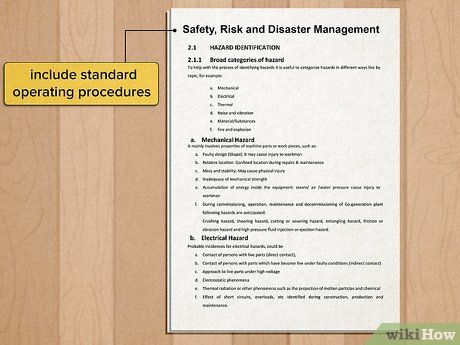

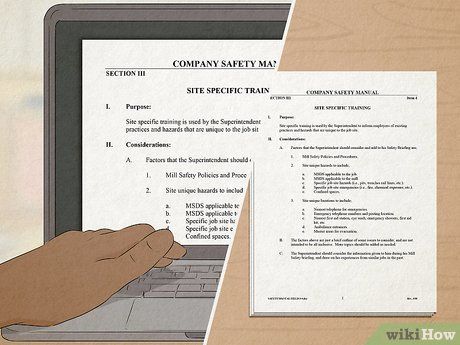

Develop Standard Operating Procedures (SOPs). Irrespective of industry, SOPs enhance workplace safety. Manuals should feature general safety advice and detailed emergency response protocols.

- Address contingencies such as fire, natural disasters, active shooter situations, gas leaks, and power outages.

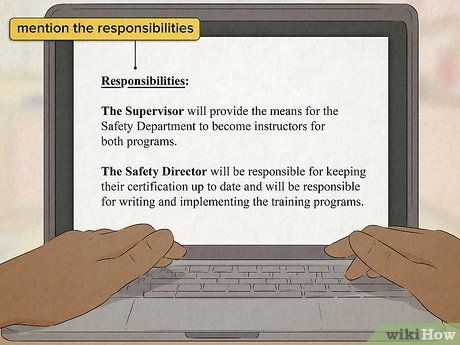

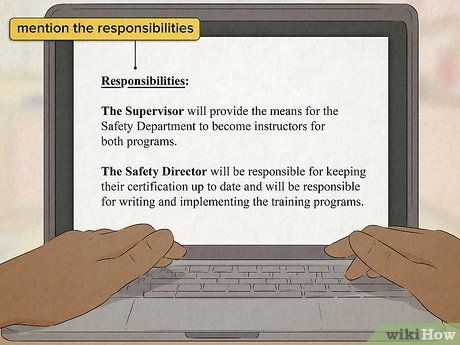

Assign Responsibility for Each Safety Step. Crucial to the manual is clarifying task ownership. Specify responsible parties for each step outlined. During manual development, identify individuals best suited for each task.

- For instance, if addressing chemical temperature maintenance, highlight the duty of the on-duty supervisor to perform hourly checks.

Engage Management in Manual Development. While technical writers may handle the actual writing, involvement of management and staff enhances acceptance within the organization. Encourage input regarding safety coverage. Request managers' input on manual sections and structure.

- Foster feedback collection via meetings, emails, or anonymous surveys.

- Solicit employee input on areas requiring guidance. While not all advice may be adopted, inclusivity promotes engagement. Consider surveying employees for information preferences.

Layout

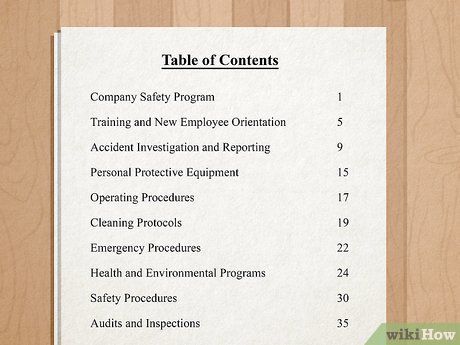

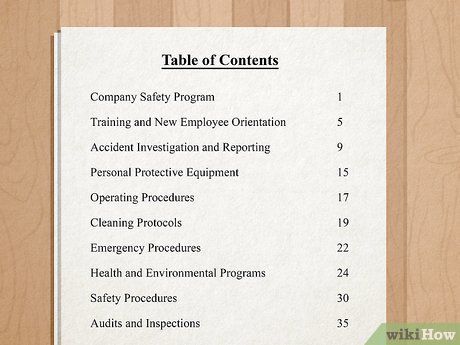

Feature a Comprehensive Table of Contents. Essential for all businesses, facilitating easy information retrieval for employees. Ensure clear, concise section headings with corresponding page references. Potential sections may include:

- Laboratory Safety

- Employee PPE

- Operating Procedures

- Cleaning Protocols

- Emergency Procedures

- Record Keeping

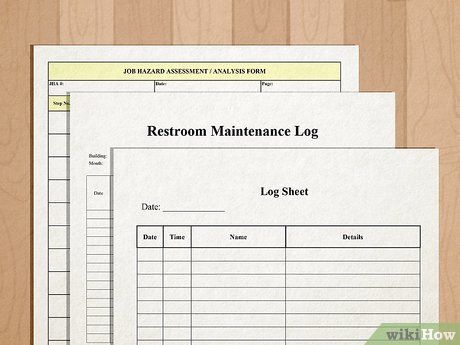

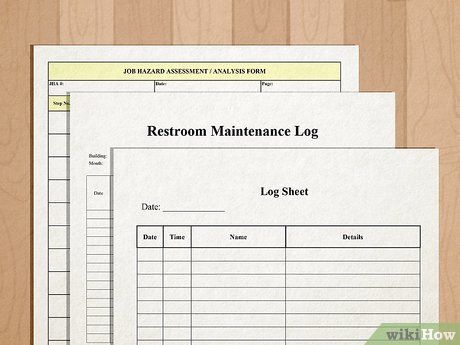

Provide Templates for Common Documents. Streamline access to essential records such as transportation and safety logs. Include template forms within the manual for easy employee reference, particularly beneficial for digital access.

- Incorporate an appendix housing documents like supply logs, cleaning schedules, and maintenance logs.

- Regularly update these documents as necessary, perhaps on an annual basis.

Maintain Updated Electronic and Paper Copies Annually. Ensure accessibility by preserving both electronic and paper formats. Strategically distribute paper copies within the premises, especially in areas prone to usage of tools and chemicals. Host an electronic version on the company website for universal access.

- Regularly review and update the manual annually to align with evolving standards and regulations, thereby sustaining its efficacy and relevance.

- Incorporate safety audits, employee feedback, and industry best practices into the update process.

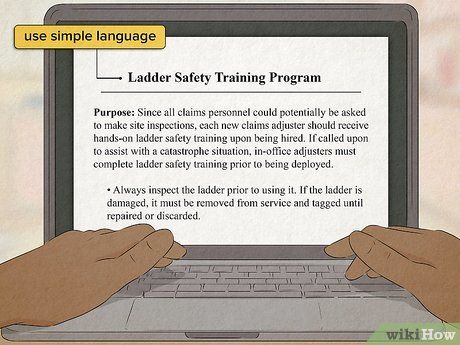

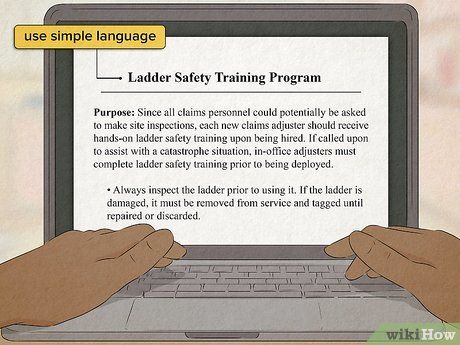

Opt for Clear, Understandable Language. Craft the manual in a manner conducive to easy comprehension by employees who interact with it regularly. Prioritize clarity by:

- Utilizing concise sentences and paragraphs featuring straightforward vocabulary.

- Employing an active voice to enhance readability.

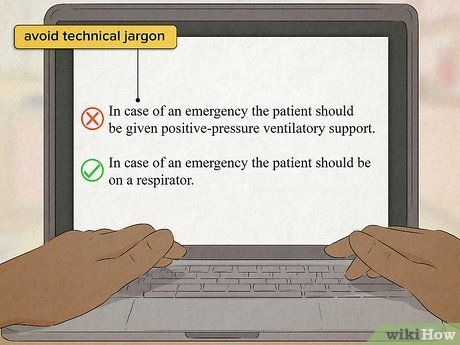

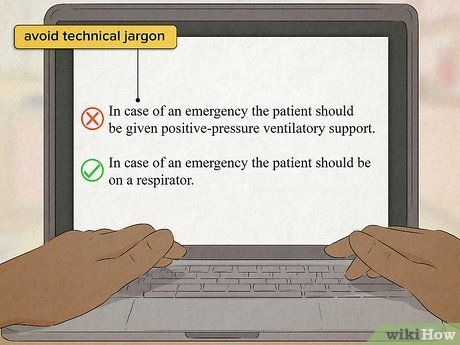

Minimize Jargon to Enhance Accessibility. Simplify terminology to ensure accessibility across all employee levels. While technical terms are acceptable, provide context and straightforward definitions.

- Clarify acronyms either in an introductory section or within the text itself, following their initial usage with the full term in parentheses.

- Explain symbols either upfront or as they appear within the manual.

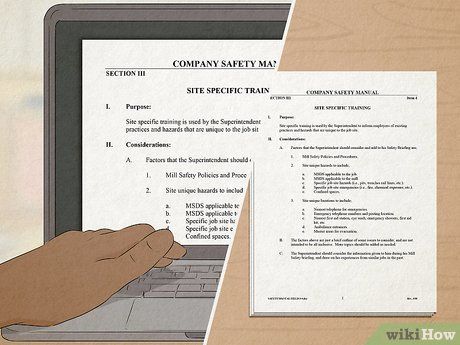

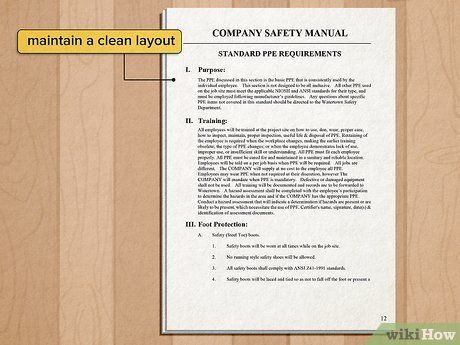

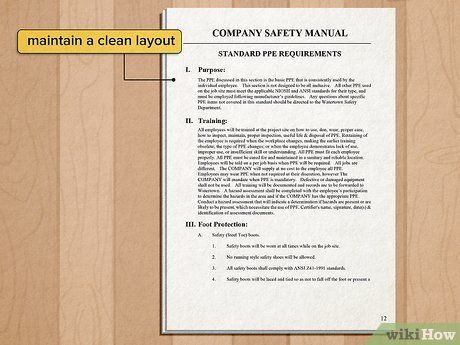

Ensure Manual Layout Facilitates Understanding. Design a cohesive layout that emphasizes key information and maintains consistency throughout. Key considerations include:

- Utilizing headings and subheadings to delineate topics and subtopics, fostering ease of navigation.

- Coordinating drawings with related text for optimal comprehension.

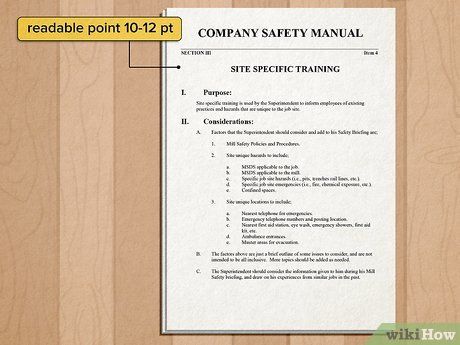

Utilize Readable Font Styles and Sizes. Opt for font sizes between 10 to 12 points for body text, slightly larger for headings. Subheadings can mirror body text size but in boldface or italics.

- Ensure optimal contrast by employing black text on white backgrounds. Consider shaded text boxes for emphasis, maintaining sufficient contrast for readability.

Helpful Hints

-

Consider utilizing an OSHA template as a foundation for ease of creation.

-

Feel empowered to update the manual as needed. While annual revision is advisable, more frequent updates are acceptable if standards evolve.