While achieving absolute fireproofing for cloth is impossible, it can be made less susceptible to ignition and sustained burning through the application of chemical mixtures commonly known as 'flame retardants'. These treatments reduce the fabric's flammability, though it's important to note that only inert materials like brick or stone can truly resist fire. Using the term 'fireproof' can be misleading since these processes only provide a retarding effect. It's crucial not to solely rely on fire retardants during a fire emergency. Instead, the best precaution is to avoid such situations altogether. Flame retardant fabric is best used in scenarios where materials may be exposed to enough heat to ignite, such as fabric near heat sources like lamps, bedding, or curtains. Conduct thorough research and exercise common sense before using flame retardants.

Preparation Steps

Select a sunny day to create flame-retardant cloth, allowing the fabric to dry outdoors and prevent chemical runoff indoors.

Alum-Based Formulation

Combine 1 pound of alum with 1 US-pint (470 ml) of hot water from a faucet in a large pan. A preserving pan works well for this, providing ample space for the fabric.

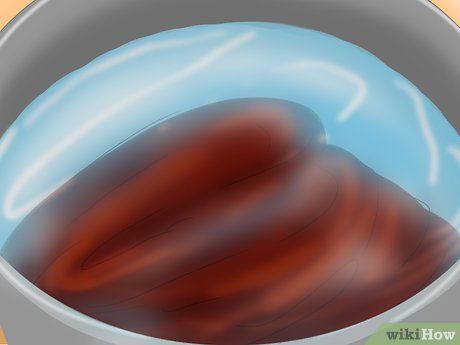

Choose the fabric you intend to treat. Submerge it fully in the pan to ensure complete saturation.

Remove the saturated fabric from the pan. Place it in a non-drip plastic basket for transportation outdoors. Hang it over the basket, on a line, or a clothes rack to dry.

Once dried, use as needed. Expect some stiffness compared to the original fabric, but it should adapt to the desired shape with bending.

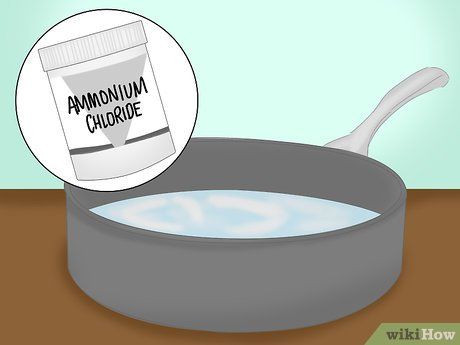

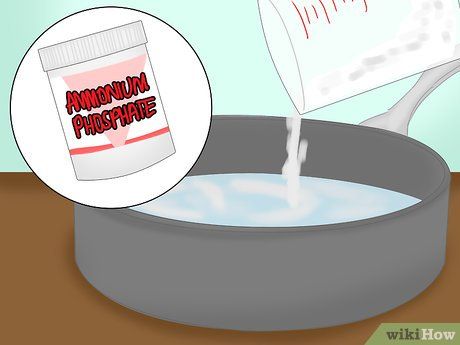

Formula using Ammonium Chloride and Ammonium Phosphate

In a large pan, combine 1 cup of ammonium chloride with 2 pints of water.

Stir in 1/2 cup of ammonium phosphate until well mixed.

Submerge the fabric in the pan, ensuring complete coverage as previously described. Dry as previously instructed.

Formula using Borax

This technique is recommended for theater scenery fabric and is particularly effective for rayon and natural fabrics.

In a large container, combine 6 parts/lbs of borax, 5 parts/lbs of boric acid, and 100 parts/12 gallons (45.4 L) of water.

Immerse the fabric until fully saturated. Repeat if necessary. Allow it to air dry.

Alternative Borax Variation

This alternative formula yields a softer, more flexible fabric and helps prevent the growth of microorganisms.

In a large container, mix 7 parts/7lbs of borax, 3 parts/3 lbs of boric acid, and 100 parts/12 gallons (45.4 L) of water.

Follow the aforementioned steps. For rayon and sheer fabrics, it's recommended to use 17 gallons (64.4 L) of water.

Formula using Sodium Silicate

This variation requires the use of gloves, as sodium silicate, also known as water glass, can be caustic to the skin and toxic if ingested.

Mix 1 ounce of sodium silicate (water glass) with 9 ounces of water.

Thoroughly wash and rinse the fabric before immersing it in the sodium silicate solution.

Allow the fabric to soak and then hang it up to dry.

Formula recommended by the National Fire Protection Association

This is another variation based on the borax methods.

Combine 9 ounces of borax powder, 4 ounces of boric acid, with 1 gallon (3.8 L) of water.

Thoroughly mix the ingredients in a large container.

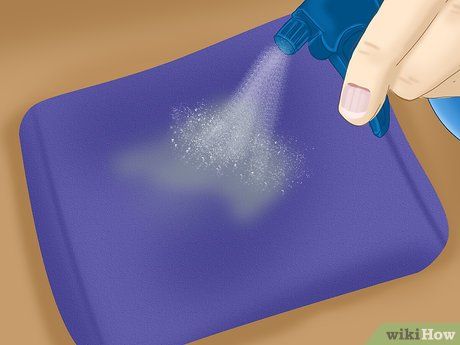

Either dip the fabric or apply the solution using a spray. Let it air dry.

Helpful Tips

-

You can find the necessary chemicals at pharmacies, chemical stores, or even garden centers.

-

According to How to Make Stuff, the second formula is suitable for treating clothing, tents, awnings, and other textiles. However, be cautious and heed Mytour's warning.

Important Warnings

- This method is recommended for fabric used in items rather than clothing. It's advisable to purchase professionally fire-treated clothing, especially if you work in an industry where fire is a hazard.

- Ensure all chemicals are stored out of the reach of children and pets.

- Check the garment's label to determine the type of treatment used, its rating, and most importantly, the proper washing and care instructions. The treated fabric may be your last line of defense in a hazardous situation.