Utility trailers are incredibly useful for a wide range of purposes, whether it's transporting your tools to a job site or your gear to an event. Whether you're considering constructing a trailer for your business needs or simply require one for occasional family outings, this guide will equip you with the necessary knowledge to construct your own!

Building Steps

Preliminary Considerations

Determine the specific type of trailer you require. Crafting a utility trailer should revolve around your specific needs. You'll need to make decisions regarding its length, weight capacity, and whether it should be enclosed. Here are a few considerations:

- If the utility trailer will primarily transport lumber or construction materials, it might necessitate stronger suspension and larger wheels. For convenient loading and unloading, especially for lengthy lumber, an enclosed structure might not be ideal. Additionally, it should be sufficiently long to accommodate lumber and sheeting.

- For transporting machinery and valuable tools, it should not only be robust but also enclosed and secure to deter theft.

- The vehicle tasked with pulling the utility trailer will also influence its dimensions. For instance, a utility trailer designed to tow groceries behind a bicycle will inevitably be much smaller than one intended for a Suburban, which might need to carry a table saw.

Choose Your Construction Approach. You can opt to construct a utility trailer from the ground up or assemble a pre-made kit. Regardless, having the right tools and materials is crucial. Explore online resources for utility trailer kit plans or visit home improvement stores or tractor supply dealers for inspiration.

Assess Your Skill Level. During the planning phase, it's vital to evaluate your proficiency in construction and mechanics. Building a utility trailer from scratch demands welding expertise, carpentry skills, and knowledge of electrical work for installing taillights. It's also beneficial if you're comfortable with heavy lifting.

Constructing the Utility Trailer

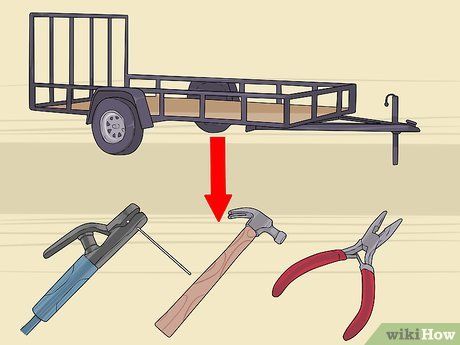

Collect Necessary Materials and Tools. Referring to a utility trailer plan will assist you in acquiring the correct components. Once you've identified a supplier for the materials, coordinate with their customer service to arrange delivery. If you possess welding skills and the required equipment, adhere to the manufacturer's safety guidelines and procedural instructions.

- Typically, designs include a bed, a hitch, a 'tongue' (the wedge-shaped extension at the front), an axle with wheels, taillights, and a license plate frame.

- Many utility trailer components (such as the tongue, hitch, axle, jack, and taillight assembly) can be purchased fully assembled, facilitating construction.

Familiarize Yourself with Local Weight Regulations Regarding Independent Brakes. If you're constructing a trailer intended for heavy loads, it must have its own brakes. Neglecting to install brakes on a heavy trailer can increase the risk of jackknifing and is unlawful.

- If you plan to use the trailer across multiple jurisdictions, verify the local weight regulations in each region you intend to visit. For example, in Canada, the weight limit ranges from 910 kg to 4,500 kg, depending on the province.

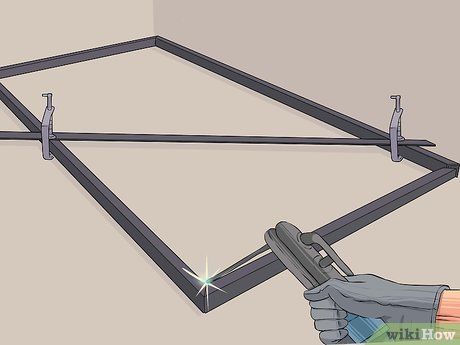

Constructing the Trailer Frame. The frame will comprise four steel angle iron rods, two for the sides and two for the front and back. Depending on the desired trailer length, the side rods may be longer than those at the front and back.

- Weld the angle iron rods together to form the bed frame, ensuring the corners are perfectly squared.

- Install support beams made of flat iron from side to side.

- Secure pressure-treated 2x6 inch (5.1 X 15.2 cm) boards to the frame, parallel to the sides within the lip of the angle iron.

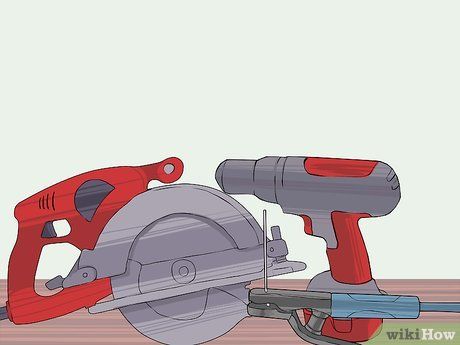

- Cut lumber using a circular saw. Drill holes in the angle iron using a variable speed drill and a drill-bit designed for metal.

- Attach the boards to the frame bed.

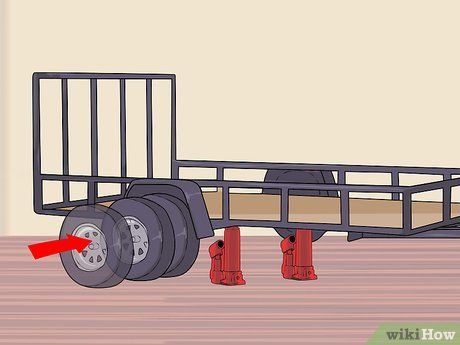

Mounting the Axle and Tires. Utilize a hydraulic jack to elevate the frame. Ensure all four corners are blocked to maintain elevation. Weld the axle beneath the frame. For a rectangular frame, position the axle with 60 percent in the front and 40 percent in the back to distribute the bed's weight.

- Install the specified tires onto the axle using lug bolts and nuts provided with the axle kit.

Completing the Remaining Components. Weld the hitch to the tongue and affix the assembly to the front of the frame. Mount the jack behind the hitch on the tongue. Route electrical wiring from the front to the rear for the taillights, ensuring the taillight connector is positioned at the front.

- The taillight assembly will include park, brake, and signal lights. Secure the wiring harness under the trailer and attach the lights to the rear using bolts on both sides.

Helpful Suggestions

-

Special procedures may be necessary to obtain a tag for your homemade trailer. In Georgia, for example, you must take your homemade trailer to a designated police station for inspection. If it passes, you'll receive a metal tag to rivet onto the frame. The unique tag number and paperwork from the police station will enable you to obtain a tag from the tag office and obtain insurance.

-

Prior to assembling tires or lights, clean and apply primer and paint to all metal parts.

Essential Tools

- Welding gear (if needed)

- Circular saw

- Variable speed drill with metal drill-bit

- Spray paint