Researchers from the Lawrence Berkeley National Laboratory in the United States have recently identified the highest hardness ever observed for a material while investigating an alloy made from chromium, cobalt, and nickel (CrCoNi). This alloy is not only extremely malleable but also incredibly rigid. What's even more remarkable is that its hardness and flexibility increase as the temperature decreases, which is contrary to most other materials. When designing material structures, we aim for them to be both hard and malleable, resistant to fracture; and scientists always compromise between these properties to create the desired material. But this new material has it all.

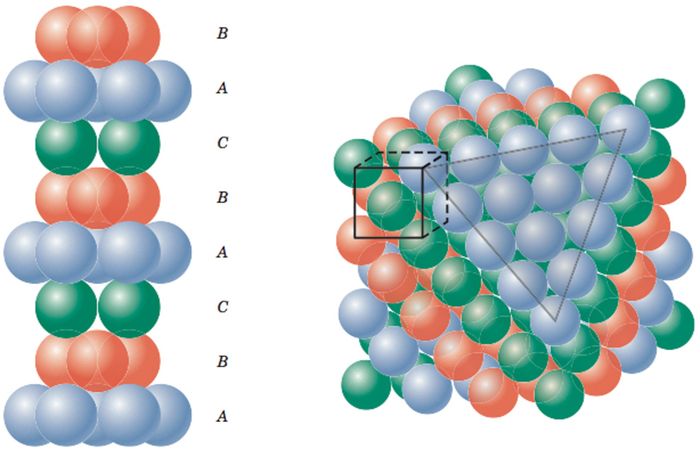

CrCoNi is a subset of a group of metals known as high entropy alloys (HEAs). All alloys used today contain a high proportion of one element combined with lower proportions of supplementary elements, but HEAs are formed from an even combination of each constituent element. This atomic-level balance seems to impart extremely high strength and flexibility under stress. HEAs have become an intriguing research field since their first development about 20 years ago, but the technology needed to push the materials to their limits under harsh conditions has only recently emerged.Exceptional Toughness: A Material Marvel

Researchers from the Lawrence Berkeley National Laboratory in the United States have recently identified the highest hardness ever observed for a material while investigating an alloy made from chromium, cobalt, and nickel (CrCoNi). This alloy is not only extremely malleable but also incredibly rigid. What's even more remarkable is that its hardness and flexibility increase as the temperature decreases, which is contrary to most other materials. When designing material structures, we aim for them to be both hard and malleable, resistant to fracture; and scientists always compromise between these properties to create the desired material. But this new material has it all.

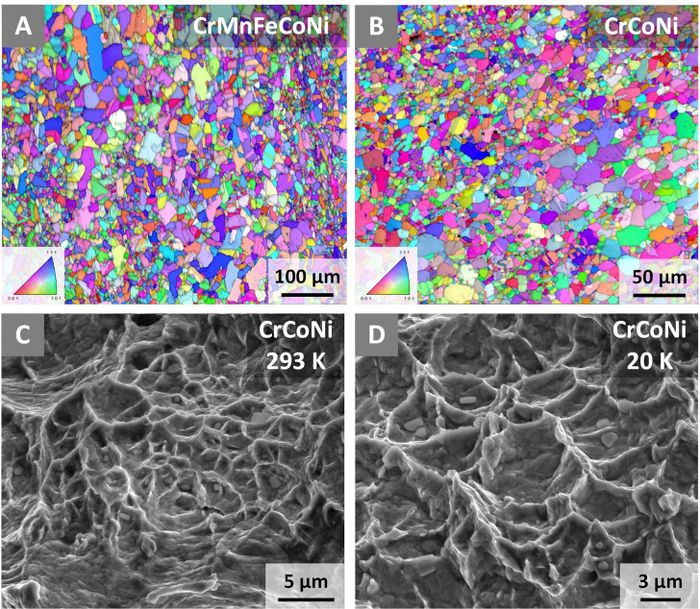

CrCoNi is a subset of a group of metals known as high entropy alloys (HEAs). All alloys used today contain a high proportion of one element combined with lower proportions of supplementary elements, but HEAs are formed from an even combination of each constituent element. This atomic-level balance seems to impart extremely high strength and flexibility under stress. HEAs have become an intriguing research field since their first development about 20 years ago, but the technology needed to push the materials to their limits under harsh conditions has only recently emerged.Exceptional Toughness: A Material Marvel A group of researchers commenced experiments on CrCoNi and another alloy containing manganese and iron (CrMnFeCoNi) almost a decade ago. They fabricated alloy samples, then lowered their temperature to near the level of liquid nitrogen (about 77 Kelvin or -200 degrees Celsius) and discovered their remarkably impressive toughness. It took them an additional 10 years to test at various temperatures due to the challenges of setting up the laboratory and recruiting researchers capable of understanding molecular-level phenomena.

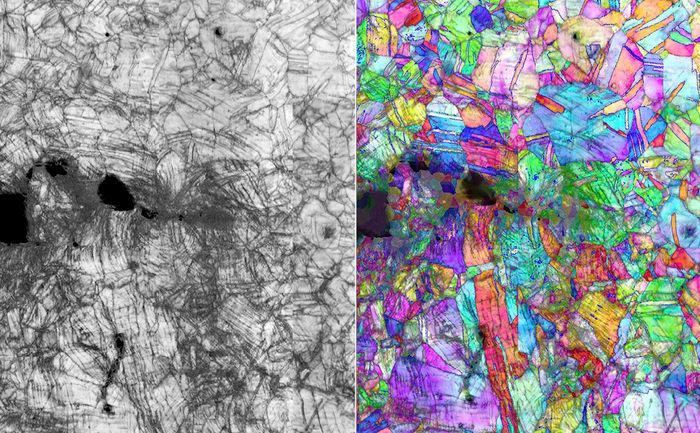

A group of researchers commenced experiments on CrCoNi and another alloy containing manganese and iron (CrMnFeCoNi) almost a decade ago. They fabricated alloy samples, then lowered their temperature to near the level of liquid nitrogen (about 77 Kelvin or -200 degrees Celsius) and discovered their remarkably impressive toughness. It took them an additional 10 years to test at various temperatures due to the challenges of setting up the laboratory and recruiting researchers capable of understanding molecular-level phenomena. Images and atomic maps from these techniques reveal that the hardness of this alloy stems from a trio of misfit obstacles shifting positions in a specific order when force is applied to the material. Initially, the misfit process causes regions of the crystal to slide out of alignment with other regions lying on parallel planes.Remarkable Atomic Interactions: Unveiling the Power of CrCoNi AlloyWith a deeper understanding of the internal workings of CrCoNi alloy, this alloy and other HEAs are edging closer to utilization in specialized scenarios. Despite the high cost of producing these materials, they are worth manufacturing for use in environments where harsh conditions could compromise conventional metal alloys, such as in the freezing temperatures of deep space.According to Berkeley Lab.

Images and atomic maps from these techniques reveal that the hardness of this alloy stems from a trio of misfit obstacles shifting positions in a specific order when force is applied to the material. Initially, the misfit process causes regions of the crystal to slide out of alignment with other regions lying on parallel planes.Remarkable Atomic Interactions: Unveiling the Power of CrCoNi AlloyWith a deeper understanding of the internal workings of CrCoNi alloy, this alloy and other HEAs are edging closer to utilization in specialized scenarios. Despite the high cost of producing these materials, they are worth manufacturing for use in environments where harsh conditions could compromise conventional metal alloys, such as in the freezing temperatures of deep space.According to Berkeley Lab.