There are numerous methods for crafting a DIY cooler utilizing easily accessible insulating materials. By utilizing a covered container, aluminum foil, and recycled packing materials, you can construct a small, uncomplicated cooler. For a larger, more efficient model, consider lining a cardboard box with foam board. For added portability, you could also sew an insulated lunch bag to maintain cold temperatures while on the move.

Steps

Constructing a Basic Cooler

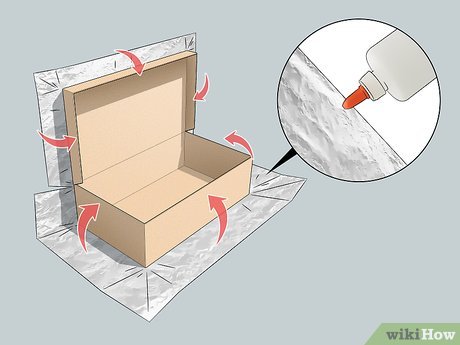

Apply foil to the exterior of a lidded cardboard or plastic container. Adhere the aluminum foil to the container and lid. Select a container large enough to accommodate the items you wish to keep cool. For instance, a shoebox or small plastic bin would suffice for storing your lunch.

- Affix the foil to the container with the shiny side facing outward. The more light the foil reflects, the less heat the container will absorb.

- Smooth out the foil after application to minimize wrinkles.

- If using a cardboard container, also glue foil to the interior. Use a single, sufficiently large sheet of foil to cover the entire inside surface. Carefully shape the foil into the corners, avoiding tears. Lining the interior with foil can prevent the cardboard from becoming damp.

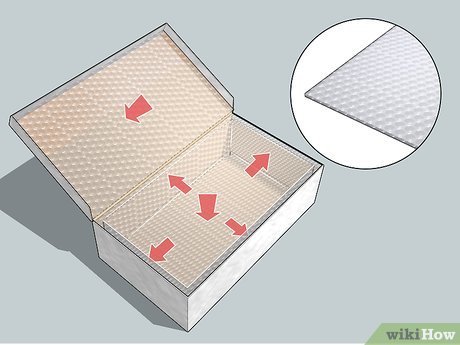

Enhance the insulation of the box by affixing bubble wrap, dense fabric, or packing peanuts. Secure your chosen insulating material underneath the lid and along the inner surfaces of the box. Opt for recycled packaging materials, sturdy nylon, or cotton for effective insulation.

- Avoid covering the rim of the lid with insulation, ensuring it still fits snugly onto the box.

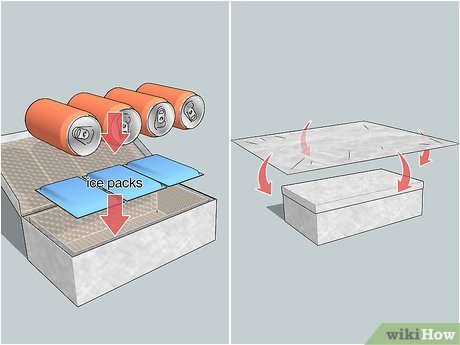

Utilize foil to seal the box if the lid lacks a tight seal. Place the items you wish to store along with an ice pack inside the box, then seal it shut with the lid. If you're using a plastic container, ensure it seals securely. For a cardboard box, cover the lid with foil, folding it over the edges and crumpling tightly around the box.

- The box should maintain the cold temperature for approximately 4 hours. If feasible, avoid exposing the box to direct sunlight or heat sources.

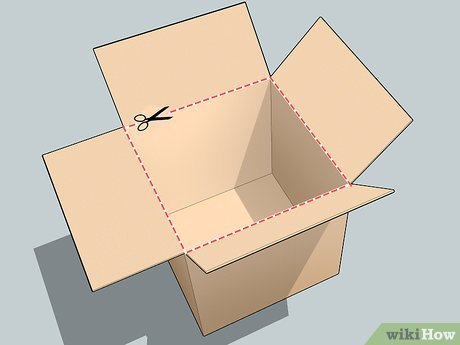

Crafting an Insulated Container

Eliminate the top flaps from a cardboard box. Employ scissors or a utility knife to remove the top flaps. Remember, you'll be layering foam approximately 6 inches (15 cm) thick within the box. Choose a sufficiently large box to accommodate the insulation while still leaving space for storing food and beverages.

- For instance, with a 24 by 24-inch (61 by 61 cm) box, the available storage space will be 18 by 18 inches (46 by 46 cm).

- Although a cardboard box is the simplest option, a sizable plastic container would suffice. Alternatively, you could construct your own wooden box.

Line the interior of the box with a trash bag, shower curtain, or plastic tablecloth. Insert a trash bag or another waterproof material into the box, mimicking the process of lining a trash can. Press the bag into the corners of the box, being cautious not to tear it. Ensure the bag lies flat against the box's sides before trimming it to align with the box's top.

- Secure the bag to the top of the box using duct tape, applying strips of tape along the entire top edge of the box. Allow some slack in the bag to prevent tearing, particularly at the bottom corners.

- The waterproof layer will prevent the cardboard from becoming soggy due to melted ice or condensation. While a trash bag is economical and readily accessible, a sturdier option such as a shower curtain or plastic tablecloth may be preferred.

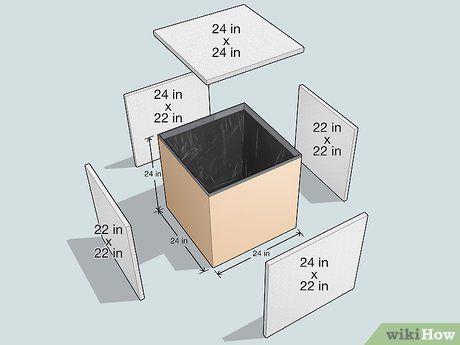

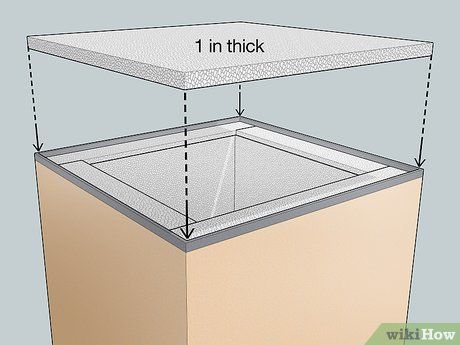

Cut 5 pieces of 1-inch (2.5 cm) foam to fit inside the box. Utilize craft foam boards or insulation foam sheets. Measure the dimensions of the box's bottom and sides, cutting one panel to match the bottom and making the side panels 2 inches (5.1 cm) shorter than the box.

- Trim 2 of the side foam panels an additional 2 inches (5.1 cm) to accommodate the thickness of the other 2 panels. For example, in a 24 by 24 by 24-inch (61 by 61 by 61 cm) box, make 2 panels 24 inches (61 cm) long, and the remaining 2 panels 22 inches (56 cm) long, each being 1 inch (2.5 cm) thick.

- When cutting, follow the grain of the foam for straighter edges.

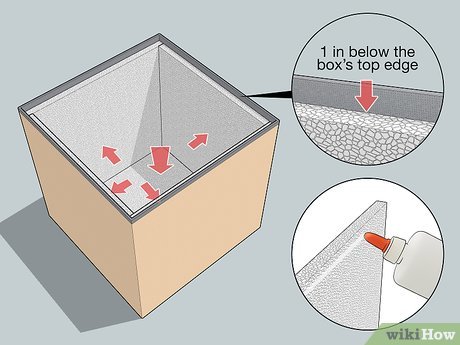

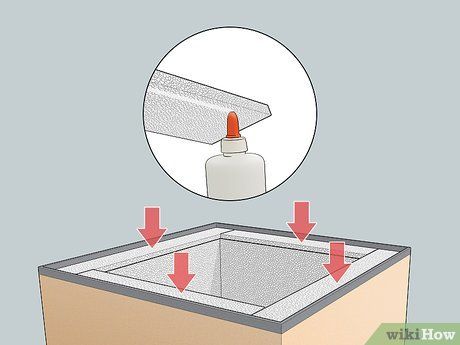

Adhere the foam panels inside the box. Begin by gluing the bottom panel to the base of the box, being careful not to damage the waterproof layer. Then affix a foam panel to each interior side of the box.

- Once in place, ensure the tops of the side panels are 1 inch (2.5 cm) below the box's top edge. Although each side is 2 inches (5.1 cm) shorter than the box, the bottom foam panel adds 1 inch (2.5 cm) to their height.

- To expedite drying, apply a moderate amount of glue onto a dry surface.

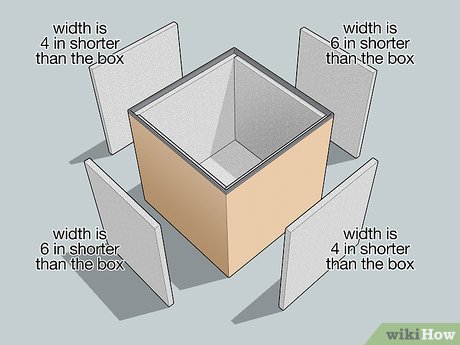

Employ 4 additional foam panels to fashion an internal box. Make 2 panels approximately 4 inches (10 cm) narrower in width than the box's sides. Cut the other 2 panels to be 6 inches (15 cm) narrower than the box's sides. All panels should be 1 inch (2.5 cm) shorter than the box's height.

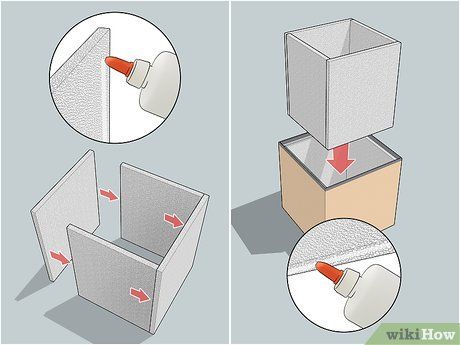

- Glue the 4 panels together to construct an inner box. This smaller inner box serves as the storage space. Fill the gap between the inner foam box and the cardboard box panels with insulation. This layered insulation will help maintain the cooler's temperature.

Secure the inner box in place. Center the foam box within the cardboard box, leaving a gap of 3 to 4 inches (7.6 to 10.2 cm) between the 2 sets of foam panels on all sides. Once satisfied with the fit, glue the inner foam box securely in place.

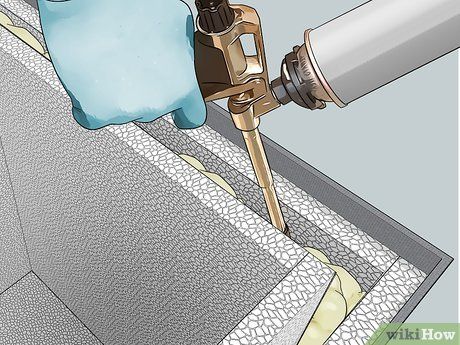

Fill the spaces between the panels with vermiculite or spray foam. Pour vermiculite between the panels or apply spray foam insulation. If using spray foam, allow it to expand between applications. If it overflows, let it dry for an hour before trimming the excess with a utility knife.

- In a pinch, use packing peanuts, bubble wrap, or Styrofoam to fill the gap. Fiberglass insulation is also suitable.

Create 4 strips of 1⁄2 inch (1.3 cm) foam board. Cut foam strips wide enough to cover the gaps filled with insulation. If each gap is 4 inches (10 cm) wide and each foam panel is 1 inch (2.5 cm) thick, the cover strips should be 6 inches (15 cm) wide.

- Cut 2 strips and place them over the gaps on opposite sides of the box. Measure the length between these 2 covers and cut 2 more strips to match that length.

- Ensure to use 1⁄2 inch (1.3 cm) thick foam board for the strips to accommodate the box's lid.

Adhere the cover strips over the gaps. Apply lines of craft glue over the foam panels lining the cardboard box and the ones forming the inner box. Then position the cover strips over the insulation-filled gaps.

- Remember to place the longer cover strips across from each other.

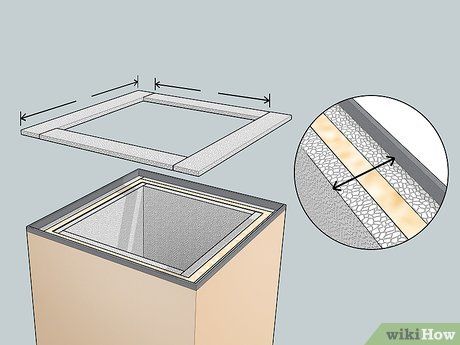

Utilize a 1 inch (2.5 cm) foam sheet for the lid. Measure the perimeter of the box's top and cut a foam panel accordingly. With the strips covering the insulation-filled gaps being 1⁄2 inch (1.3 cm) thick, a 1⁄2 inch (1.3 cm) lip should form along the sides of the cardboard box, fitting snugly around the lid.

- If desired, attach handles or knobs to the lid for easier removal. For a wooden box, consider crafting a wooden lid lined with foam and hinged to the box.

Crafting an Insulated Lunch Bag

Choose waterproofing, insulation, and outer materials. Opt for waterproof material for the innermost layer, insulation for the middle layer, and a visually appealing fabric for the outer layer.

- Laminated cotton, PUL lining, and vinyl are recommended for waterproofing. Alternatively, consider using a recycled plastic tablecloth or shower curtain.

- For insulation, thermal batting from a fabric or craft store is ideal. Alternatively, recycle thin flexible foam or bubble wrap. Thin craft foam or packing foam can also be used, but may result in a stiffer lunch bag.

- Select a durable and easy-to-clean material such as canvas or denim for the outer layer.

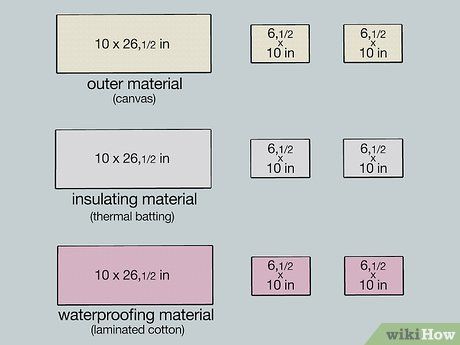

Create 3 rectangles from each material. Cut a 10 by 26 1⁄2 inch (25 by 67 cm) rectangle for each material. Additionally, cut a pair of 6 1⁄2 by 10 inch (17 by 25 cm) rectangles.

- You should end up with 1 large and 2 smaller rectangles for each of the 3 materials, totaling 9 rectangles.

Attach the insulation to the outer fabric. Lay the outer fabric rectangles flat on your work surface. Apply a small amount of fabric adhesive around the edges, corners, and center of the outer fabric. Then place a corresponding piece of thermal batting over it and press the fabric and batting together.

- Repeat this process for the other 2 sets of fabric and batting rectangles.

- You can find spray adhesive online or at craft and fabric stores.

- Spray basting is the simplest way to attach the batting to the outer fabric. Alternatively, you can secure them together by pinning them 1⁄4 inch (0.64 cm) from the edges.

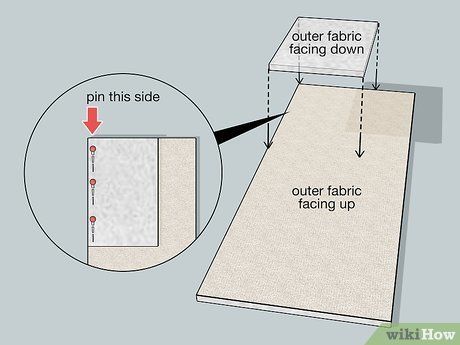

Attach 1 side panel of the outer material to the main section. Spread out the large rectangular section of basted outer material with the outer fabric facing up. Place a smaller rectangle of basted outer material over the large one with the outer fabric facing down. Align the upper left corners of both rectangles and pin together their left long edges.

- Secure the pins into the fabric rectangles 1⁄4 inch (0.64 cm) from the edges.

- Ensure alignment of the long and short sides of the rectangles. Orient them so their short sides are at the top and bottom, and the long sides are on the left and right.

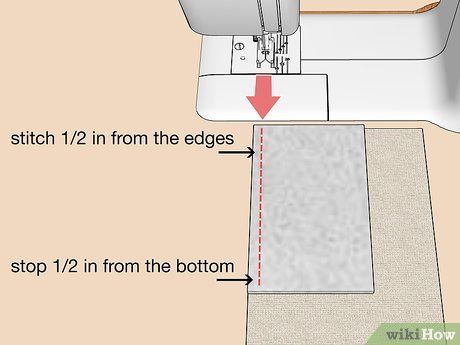

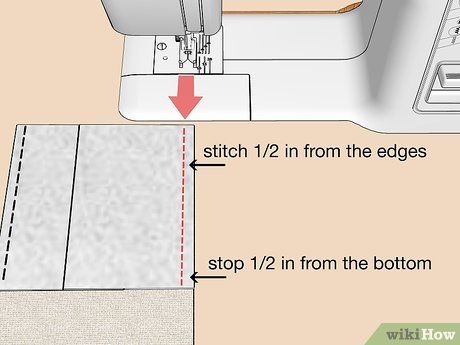

Stitch the pinned edges of the side and main panels. Sew down the pinned sides of the panels 1⁄2 inch (1.3 cm) from the edges. Begin at the top corner and sew down the long side, stopping 1⁄2 inch (1.3 cm) away from the bottom left corner of the side panel.

- Use this 1⁄2 inch (1.3 cm) seam allowance for all stitches in this project.

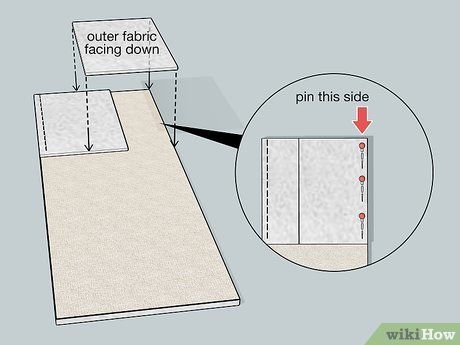

Pin the second side panel to the main body. Place the second panel over the main body with the outer fabric facing down. Align the upper right corners of the main panel and second side piece, and pin down their long sides on the right.

Sew the second side panel to the main body. Stitch along the pinned right edges of the main and side panels, stopping 1⁄2 inch (1.3 cm) above the bottom right corner of the side panel. This should mirror the sewing of the left side panel.

- Ensure to maintain a 1⁄2 inch (1.3 cm) seam allowance.

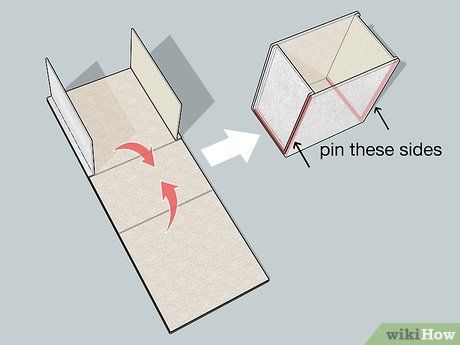

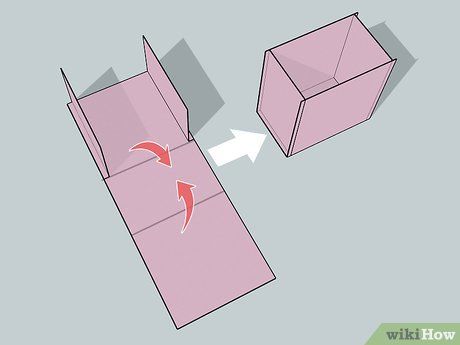

Pin the remaining edges to form a bag shape. Raise the left side panel straight up so it's perpendicular to the main panel. Fold the main panel upwards to align its bottom left corner with the top right corner of the left side panel. Pin the panels together from the top right corner of the side panel to its bottom right corner.

- Repeat this process for the right panel, aligning its top left corner with the bottom right corner of the main panel.

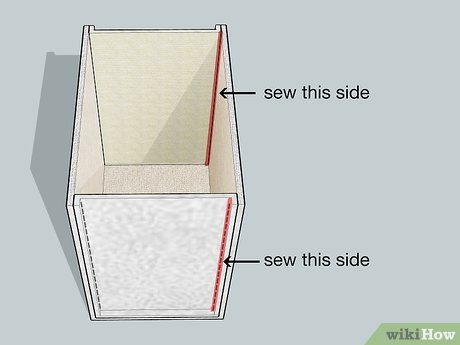

Sew along the pinned edges. Stitch the left side panel to the main panel along the pinned edge, stopping 1⁄2 inch (1.3 cm) above the bottom edge of the side panel at its bottom right corner. Then sew the right side panel to the main panel along the pinned edges.

- You should now have a rough bag shape with an open top and unstitched bottom. Both long sides of the side panels should now be fully sewn to the main panel.

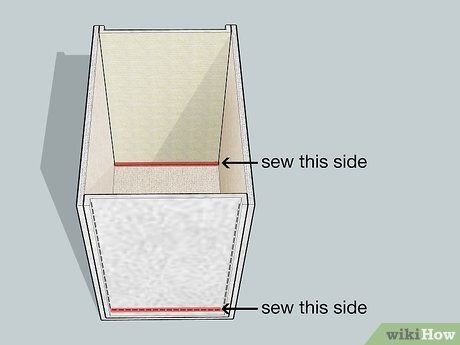

Sew around the base of the bag to flatten the bottom. Stitch the short sides of the side panels to the main panel's bottom. After sewing each short side, add extra stitch lines along the bottom of the bag's long sides to create a flat base.

- All edges of the bag should now be stitched except for the top opening.

Repeat the process to make the waterproof lining. Position a waterproof material side panel over the large waterproof rectangle, aligning their upper left corners. Stitch the panels' left sides together, then sew the right side of the other panel to the right side of the main body. Fold up the main body to match its bottom corners with the side panels' top corners, then sew the edges to form a rough bag shape.

- Finish by sewing around the bottom edges of the waterproof lining to flatten it.

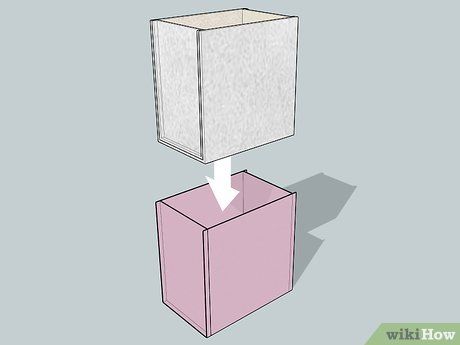

Insert the outer cover into the inner lining. Keep the inner lining facing outward and reverse the outer cover. Then insert the outer cover into the inner lining.

- Ensure a snug fit between the two pieces, aligning all four edges around the opening and matching the stitched edges of the side panels.

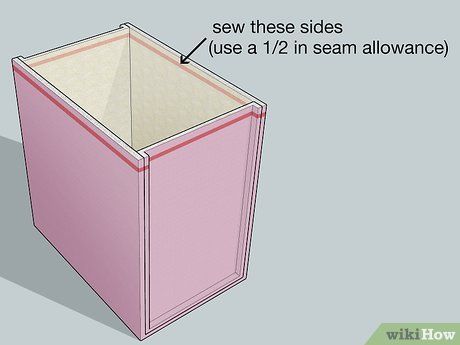

Sew along all four top edges. Secure the top edges of both the outer bag and liner with pins or clips. Stitch all around the top edge to join the liner to the outer cover.

- Once again, maintain a 1⁄2 inch (1.3 cm) seam allowance.

- Overlap the beginning and ending stitches for added thread security.

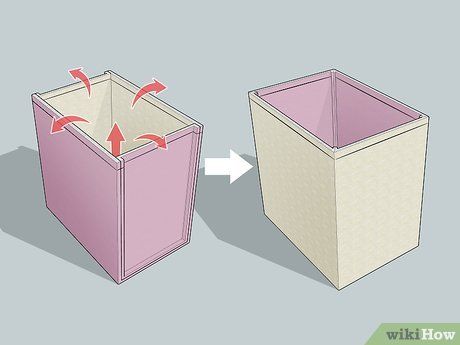

Turn the cooler inside out. With the outer and inner layers now connected, reach into the bag's opening, pull up the bottom, and flip all the material inside out.

- The outer cover's correct side should now be visible externally, and the waterproof layer should be visible inside the cooler.

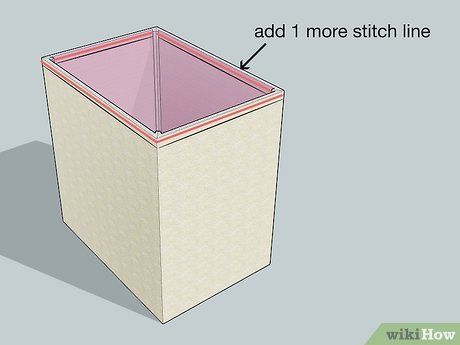

Reinforce the junction of the lining and outer fabric with an additional stitch line. Locate the seam where the waterproof liner meets the outer fabric. Stitch a line directly along this seam all around the bag's opening.

- This final stitch will provide additional support to the opening, securing the lining and outer fabric together.

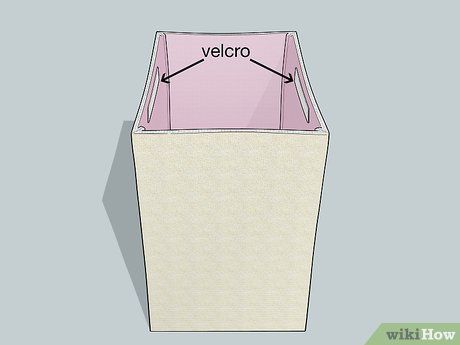

Attach Velcro or magnetic strips for bag closure. Use fabric adhesive or a hot glue gun to affix Velcro, magnets, or snaps to the inner edges of the bag's long side. To close the bag, fold the sides inward and fasten the Velcro, magnets, or snaps.

- And there you have it! Enjoy your newly crafted insulated lunch bag!

Helpful Tips

Essential Items

Basic Cooler

- Lidded plastic or cardboard box

- Aluminum foil

- Craft glue

- Packaging peanuts, thick fabric, or bubble wrap

Insulated Container

- DIY Insulated Lunch Bag

- Materials for Making an Insulated Lunch Bag