The printing industry has navigated through diverse epochs, evolving into a prominent printing sector we experience today. In this industry evolution, one cannot ignore the impact of offset printing – an industrial method that has brought us seemingly small but immensely significant advancements.

1. Understanding Offset Printing

Offset printing is an industrial printing technique with a process as follows: Inked images adhere through offset plates (rubber sheets), and printing paper passes through these offset plates with sufficient force to shape the images. When combined with lithographic printing, offset prevents water from sticking to the print template. This is achieved by configuring the ink roller to print within the image area, while the water roller is designated for non-image areas.

2. Why Opt for Offset Printing?

Let's skip the discussion on the merits of offset printing, such as high speed, excellent print quality, and cost-effectiveness for large quantities. Additionally, notable advantages of this method include:

- Consistent and Uniform Image Quality: Offset printing produces even, beautiful images by pressing them onto rubber sheets with just the right force, ensuring even ink distribution on the paper.

- Printing on Various Materials: Besides paper, this method can print on diverse materials like wood, leather, metal, sandpaper, and more.

- Robust Print Longevity: Employing a technique based on templates, pre-made molds, and pressing onto the printing material, this method ensures the ink adheres firmly, resulting in better print longevity compared to the technique on inkjet printers that spray images onto paper using image drum.

- Reduced Printing Costs for Large Quantities: Offset printing utilizes pre-made templates and runs on assembly lines, leading to time savings and even ink distribution, preventing ink wastage for large-scale printing.

For publishing houses, businesses employing advertising through flyers or catalogs, offset printing significantly reduces costs and printing time compared to other methods.

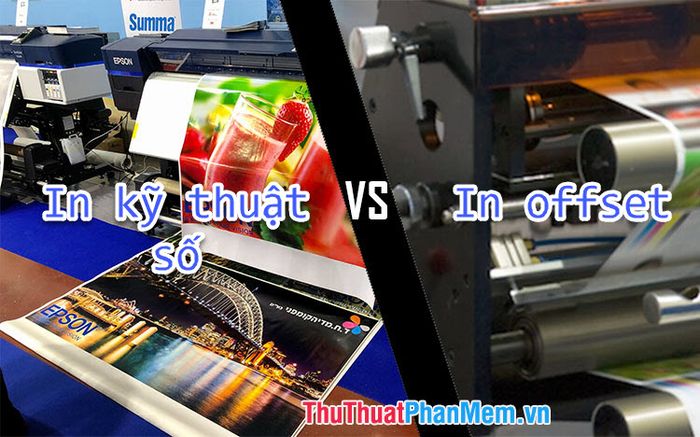

3. How Does Offset Printing Differ from Digital Printing?

Both offset printing and digital techniques deliver excellent and swift print quality. However, the choice between the two depends on the print volume, whether for commercial purposes or other needs. Additionally, refer to the comparative table below:

Đặc điểm |

In kỹ thuật số |

In offset |

Số lượng, kích cỡ bản in |

- In với số lượng ít |

- In với số lượng lớn, có thể lên tới hàng nghìn, triệu bản in. |

Màu sắc bản in |

- Phụ thuộc vào công nghệ của máy in, mực in. |

- Phụ thuộc vào người pha mực, yếu tố môi trường, thời tiết. |

Cách thức in |

- Dùng trống mực (ink drum) để tiếp nhận hình ảnh từ máy tính, thiết bị nguồn bằng các ion, sau đó nhận mực rồi ép mực lên giấy thành bản in hoàn chỉnh. |

- Dùng ống kim loại khắc sẵn hình ảnh cần in. Sau đó, giấy in được ép qua tấm offset bằng cao su với mực và hình ảnh sẵn có. |

Thời gian chuẩn bị |

Nhanh |

Lâu |

Tốc độ in |

Chậm |

Nhanh |

Chi phí khi in |

Chi phí tỉ lệ thuận với số lượng: |

Chi phí tỉ lệ nghịch với số lượng: |

With insights and a comprehensive understanding of offset and digital printing methods, you can discern and select the most suitable and optimal printing approach for yourself. Wishing you a wonderful day ahead!