Spandex fabric stands out as a widely utilized material in today's fashion industry. It's a synthetic fiber known for its exceptional elasticity. But what exactly is spandex? What makes it special, and how is it produced and applied? Join us on this journey to delve deeper into the world of spandex.

Unveiling the Essence of Spandex

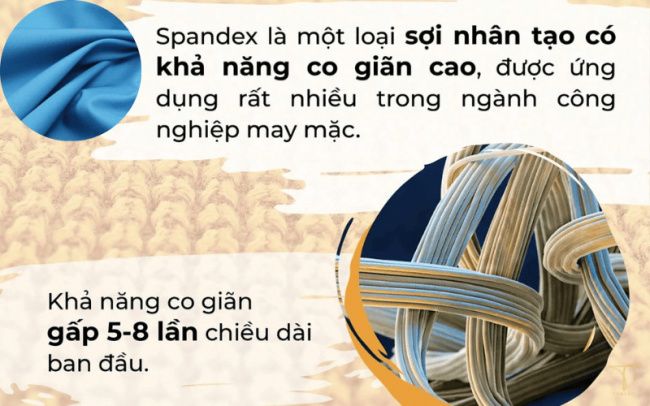

Often referred to as Lycra or Elastane, Spandex is the epitome of high elasticity, durability, and wrinkle resistance. With a stretching capability five times its original size, it outshines even natural rubber. Let's explore the marvels of Spandex in the fabric realm.

The Genesis of Spandex: A Fusion of Polyurethane and Polyester

In the realm of fashion, products crafted solely from 100% Spandex fibers often bear a hefty price tag. Manufacturers, therefore, opt to blend Spandex with other types of fibers to cut costs and mitigate any shortcomings in Spandex threads.

Origins and Evolution of Spandex Material

Since World War II, the concept of Spandex emerged with the aim of creating a highly elastic synthetic material as a substitute for natural rubber. Pioneering this innovation was the scientist from Farben Fabriken Bayer. Despite its inception, practical application remained experimental in nature.

In 1959, scientists at the DuPont Research Institute (Waynesboro) conducted extensive research and introduced the final version of Spandex, then known as Lycra. By 1962, Spandex gradually gained popularity, finding applications in the fashion industry, sportswear, bedding, and interior furnishings.

In each region or territory, this type of Spandex fiber is referred to by different names:

The Process of Crafting Spandex Fiber

With the insights provided, you now have a better understanding of what Spandex is and its origins. The production of Spandex fiber involves a complex and time-consuming process, as outlined below:

1. Step 1: Prepolymer Formation

In this phase, a blend of diisocyanate monomer and glycol in a 2:1 ratio is reacted in a vessel, resulting in the creation of prepolymer.

2. Step 2: Fiber Drawing Solution

After the prepolymer is generated, manufacturers initiate a reaction with diamine in a 1:1 ratio (an extensive chain reaction). Following this reaction, a compound in solution form is obtained, and a solvent (DMAc) is further employed to dilute the solution. Subsequently, a fiber drawing solution is produced.

3. Step 3: Spinning the Fiber

Proceed to pump the obtained fiber drawing solution from the previous step into a cylindrical spinning machine to create Spandex fibers. During the spinning process, the fibers are heated with nitrogen gas and chemical solvents to induce chemical reactions in the liquid polymer, ultimately forming solid fibers.

4. Step 4: Creating Spandex Fibers

Upon completing the fiber spinning process, solid fibers are obtained. These fibers are gathered and assembled to produce the final Spandex fibers with the desired thickness. Each finished Spandex fiber is composed of numerous individual, intertwining threads.

5. Step 5: Processing Spandex Fibers

To prevent Spandex fibers from sticking together during processing, Magnesium Stearate or another polymer is applied. Subsequently, the Spandex fibers are transferred over rollers onto thread tubes and woven into fabric.

6. Step 6: Quality Inspection

In this phase, meticulous checks are conducted on standard dimensions and the stretchability of the fabric to ensure high-quality output. Following this, the Spandex fabric meeting the quality standards is introduced to the market for consumption and application in various fields.

Common Types of Spandex Fabrics Today

In the current market, three popular types of Spandex fabrics prevail: Cotton Spandex, Polyester Spandex, and Knit Spandex.

1. Cotton Spandex Fabric

What is Cotton Spandex? It's a fabric created by blending Spandex and cotton fibers. Cotton Spandex inherits the exceptional qualities of both cotton and Spandex, offering excellent elasticity, lightness, softness, and high absorbency.

In addition, this fabric is resistant to dust accumulation and easy to maintain cleanliness. Hence, it finds widespread applications in sportswear, outdoor gear, dresses, and office T-shirts.

2. Polyester Spandex Fabric

What is Polyester Spandex? It's a fabric crafted by combining Spandex and Polyester materials. Polyester Spandex possesses notable features: excellent elasticity, breathability, and high aesthetic appeal. Consequently, this fabric is often employed in the production of dresses, T-shirts, or party attire.

3. Knit Spandex Fabric

This fabric is a fusion of wool and spandex fibers. The standout features of Knit Spandex fabric include excellent elasticity, stretchability, and durability. Therefore, it is commonly used for designing winter garments or team/family uniforms.

Pros and Cons of Spandex Fabric

Spandex material is currently prevalent and favored in today's market. This fabric possesses numerous advantages and high versatility; however, it also comes with some limitations. Let's delve into the specifics of the pros and cons of Spandex right away.

1. Advantages

- Exceptional Elasticity and Stretch: Spandex is the fabric with the highest stretchability and elasticity today. Notably, it can endure pulling forces up to 5 times its original shape without stretching or tearing.

- Lightweight and Durable: Spandex material is incredibly lightweight, soft, and resistant to pilling, stiffness, or fiber distortion after repeated use. It also exhibits excellent resistance to abrasion.

- Anti-Static Properties: Spandex fabric effectively resists static electricity, preventing clinging and discomfort when wearing during the winter months.

- Skin-Friendly: Among synthetic fabrics, Spandex is known for its softness and skin-friendly properties, ensuring comfort for your skin.

2. Disadvantages

- Poor Moisture Absorption: This material often leads to discomfort and stickiness for the wearer due to its low ability to absorb sweat and moisture.

- Susceptible to Corrosion from Bleaching Agents: Spandex fabric quickly deteriorates when exposed to various laundry detergents or high pH substances.

- Prone to Yellowing with Prolonged Use: Without proper care and storage, products made from Spandex fabric are prone to yellowing after extended periods of use.

- Limited Heat Resistance: Exposure to high temperatures can easily cause this material to wrinkle or melt.

- Environmental Pollution: Spandex, being a synthetic fabric, is challenging to decompose, and its recyclability is very limited.

Applications of Spandex Fabric in Daily Life

Currently, Spandex fabric is widely popular and finds various applications in our daily lives. Specifically, it is used in:

- Used in designing various garments such as swimwear, lingerie, sportswear, swimsuits, skinny jeans, and snow pants.

- Popular for creating form-fitting pants or attire for athletes involved in rowing, cycling, and other activities.

- Additionally, Spandex fabric is applied in making gloves, antimicrobial pillows, orthodontic products, seat covers, bedding, and dance belts.

Maintaining Hygiene and Preserving Spandex Fiber Products

To ensure longevity and minimal wear for products made from Spandex fabric, it's crucial to consider the following during cleaning and storage:

- Hand wash with a mild detergent in warm water for Spandex-based items. In case machine washing is necessary, avoid using the spin cycle.

- Air-dry garments in a cool, shaded area, avoiding direct sunlight, and refrain from using a dryer.

- Limit ironing, and if needed, iron only the fabric's reverse side at a low temperature.

Posted by: Dũng Nguyễn

Keywords: Understanding Spandex – Classifications, Characteristics, and Applications of Spandex Fabric