Large dry erase boards are invaluable for organizing and displaying information. Save money by creating your own instead of purchasing them. Utilize inexpensive materials like plastic and foam to construct a sizable board that can be mounted on the wall. For magnetic functionality, consider painting a steel sheet. Alternatively, use paper and plastic to craft portable smaller boards. Design your whiteboard for note-taking, jotting down reminders, and simplifying daily tasks.

Procedures

Constructing a Plastic or Foam Board

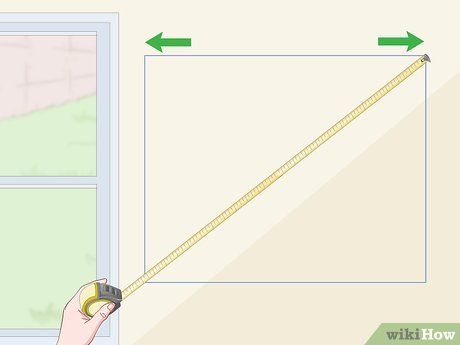

Customize the board to fit your available space. The size of your homemade board is flexible, but it should align with your wall dimensions. Prior to purchasing materials, measure the space where you intend to hang the board. Record the measurements and bring them along when shopping. Typically, whiteboard materials are sold in 4 ft × 8 ft (1.2 m × 2.4 m) sheets, but other sizes can be ordered from home improvement stores if needed.

- If the desired size isn't readily available, inquire about custom sizing options at your local store.

Opt for a melamine sheet to create a classic whiteboard. Melamine, a fiberboard sheet with a durable coating, is commonly used in store-bought whiteboards. Opt for a smooth surface for better erasability and aesthetic appeal. While porcelain is more durable, it comes with a higher price tag.

Consider a plastic sheet for a transparent board. Plexiglass or Lexan offer unique options for clear boards. Transparent acrylic or polycarbonate sheets allow for a see-through effect, akin to writing directly on the wall. Opt for Lexan for its thinner profile, lighter weight, and shatter-resistant properties.

Invest in wood trim to construct a frame for the board. Select molding longer than the board's dimensions to fashion a picture frame. Wood trim not only conceals the board's edges but also enhances its appearance and facilitates hanging. Repurpose wood scraps for a budget-friendly alternative to store-bought molding.

Use a miter box to measure and cut the wood trim. Mark the wood according to the whiteboard's dimensions and cut at a 45-degree angle using a hand saw. Ensure proper fit by aligning the wood pieces like a picture frame. Sanding with 120 and 220-grit sandpaper prepares the wood for staining.

Smooth the wood with 120 and 220-grit sandpaper if staining. Sanding aids in stain adhesion, starting with 120-grit sandpaper and finishing with 220-grit for a polished finish. Follow the wood's grain to prevent scratches.

Apply a wood staining product to enhance its color. Use a foam brush to evenly spread the stain along the wood grain. Let it set for up to 15 minutes before applying additional coats for a richer hue. Remember to wear gloves and wipe off excess stain with a rag.

Secure the wood frame to the board using clear epoxy. Ensure the frame fits snugly over the board edges before applying glue. Spread epoxy on the back of the frame boards and attach them to the whiteboard, clamping if necessary. Apply glue to the frame board edges for added stability.

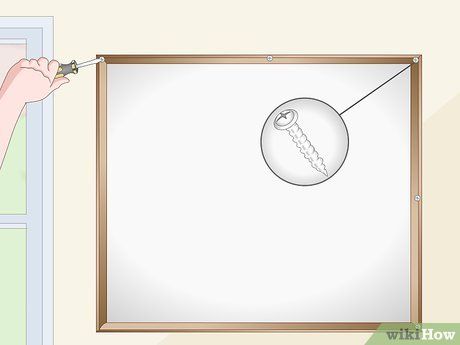

Mount the board onto the wall using screws. Space screws evenly along the frame, securing them into wall studs for stability. Use a cordless screwdriver and a stud finder to locate the studs.

Crafting a Magnetic Metal Board

Purchase a sheet of metal for the desired board size. Opt for thin and durable metal, such as galvanized steel for magnetic functionality. Avoid aluminum, as it lacks magnetic properties.

Reinforce the board with a wooden backing. Enhance the mobility and hanging capability of your metal board by adding a supportive back. Opt for lightweight and soft materials like cork or plywood.

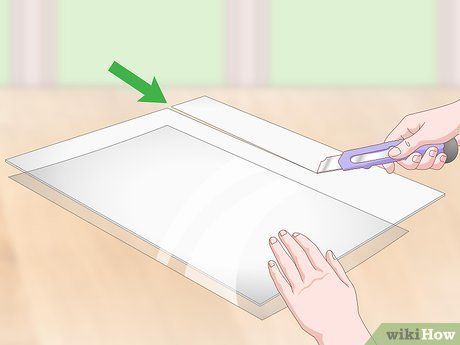

Trim the metal to size using tin snips if necessary. Adjust the size of the metal sheet according to your space constraints. Use straight-cutting tin snips to carefully trim the metal.

Apply a primer to the metal surface for painting. Prepare the metal for painting by applying a rust-resistant latex primer. Ensure a clean surface by wiping off any dirt or residues before priming.

Coat the metal with whiteboard paint for a white surface. Follow the mixing instructions provided with the paint. Use a foam roller to apply the paint evenly, creating a smooth writing surface.

Allow 10 to 15 minutes between paint layers. Apply additional layers of paint as needed to achieve the desired thickness. Ensure each layer is evenly applied and allow drying time between coats.

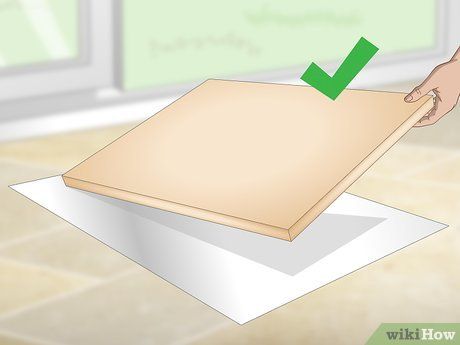

Adhere the painted metal to the backing using epoxy. Wear rubber gloves while handling epoxy. Mix it thoroughly and spread it evenly over the backing before placing the metal on top. Consider alternative adhesives like polyurethane-based super glue or silicone construction adhesive.

Allow 72 hours for the paint and glue to fully cure. Ensure the board is completely dry before use. Once cured, you can safely hang the board without the risk of it falling.

Hang the board using adhesive picture-hanging strips. Apply strips to each corner of the board's back and firmly press it against the wall. Alternatively, consider other hanging options such as attaching magnets with strong adhesive or using metal picture hangers.

Creating Portable Paper Whiteboards

Utilize plastic covers or wraps for makeshift whiteboards. Report covers are cost-effective and ideal for small whiteboards. Look for different sizes depending on your needs. They are readily available at general and office supply stores.

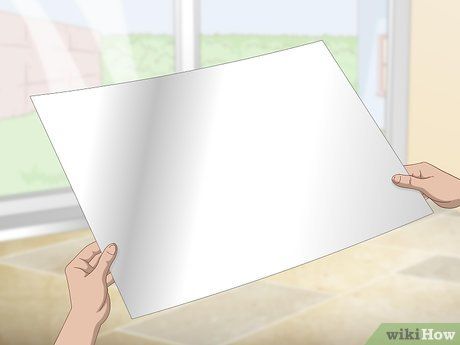

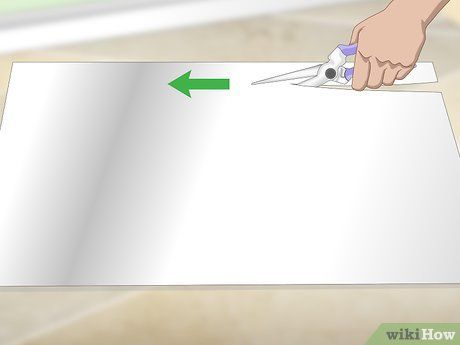

Cut white card stock to match the cover size. Card stock provides a sturdy base for writing. If using paper, trimming might be necessary. Paper whiteboards offer flexibility, allowing easy swapping for different tasks, ideal for students.

Mark borders for added aesthetics. Apply colorful duct tape around the edges of the plastic sheets. Outline the tape's width using a washable marker, ensuring it wraps around both front and back covers.

Secure the plastic covers with tape. Wrap tape around the edges to hold the covers together. Leave one side open for paper swapping. For permanent setups, tape all sides before inserting the card stock.

Handy Tips

- Remove stains from melamine boards with diluted isopropyl alcohol. Applying car wax makes erasing marks easier.

- Convert a regular whiteboard to magnetic using magnetic paint covered with whiteboard paint.

- Create sections on your whiteboard with automotive pinstriping from an auto parts store.

Important Notes

- Exercise caution when cutting materials. Always wear protective gear and handle saws responsibly to avoid accidents.

Essential Supplies

Materials for Constructing a Plastic or Foam Board

- Melamine, plexiglass, or Lexan board

- Wood trim

- Hand saw or miter saw

- Miter box

- Epoxy glue

- Wood staining product

- Foam brush

- Wooden stirrer

- Cordless screwdriver

- 2 in (5.1 cm) drywall screws

- Stud finder

Constructing a Magnetic Metal Surface

- Galvanized steel sheet

- Wood or cork backing

- Rust-resistant latex primer

- Whiteboard paint

- Wooden stirrer

- Epoxy glue

- Picture-hanging strips

- Optional: Magnets

- Optional: Tin snips

Creating Compact Paper Boards

- Report cover or plastic wrap

- Card stock

- Scissors

- Ruler

- Duct tape