Various heavy-duty equipment relies on hydraulic systems to power their mechanisms. Over time, hydraulic hoses degrade and may develop leaks, compromising equipment functionality. To restore optimal performance, it's essential to replace worn-out hoses promptly. Begin by identifying the damaged hose, then proceed to detach it by unscrewing it from the equipment. Finally, procure a suitable replacement hose and install it to ensure smooth operation of the system.

Procedural Steps

Procedure for Hose Removal

Ensure Personal Protection with Goggles and Gloves: Hydraulic fluid is hazardous and can cause harm upon contact with skin or eyes. Wear goggles and gloves throughout the handling of hydraulic materials, maintaining protection until the task is complete.

- Consider wearing long sleeves and pants for additional skin coverage during pipe replacement.

- If working in an inadequately ventilated area, wear a mask or respirator as well.

- In case of fluid contact with skin, eyes, or ingestion, promptly seek assistance from the local poison control center.

Ensure Hydraulic System Pressure Release: Prior to any work on a hydraulic machine, it's imperative to release all pressure within the system. Failure to do so may result in hazardous hydraulic fluid discharge, posing risks of injury. The method for pressure release varies depending on the equipment type. Refer to the owner’s manual for precise instructions.

- Typically, hydraulic equipment features a pressure-release lever. Initiate pressure release by activating this lever first. Subsequently, deactivate all power sources to the hydraulic system. Finally, cycle the hydraulic lever several times to expel residual pressure.

- If working with equipment that raises, such as a backhoe, lower the mechanism completely before commencing work.

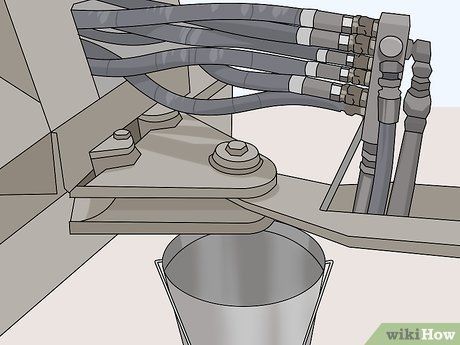

Place a Protective Barrier Beneath the Hose: When removing a hose, hydraulic fluid leakage is inevitable. Prevent contamination by positioning a sheet or bucket underneath to collect leaking fluid. Employ a sturdy drop cloth or bucket to contain the oil spill.

- If positioning a sheet or bucket proves challenging, use rags to absorb leakage instead.

Remove Obstructive Coverings: Certain equipment features protective hoods or coverings around hoses, particularly at attachment points. Remove any such coverings to facilitate hose maintenance.

- Maintain a record of removed components. Capture a pre-removal image of the equipment for reference during reassembly.

- Consult the owner’s manual for specific hose removal procedures, as they may vary between equipment models.

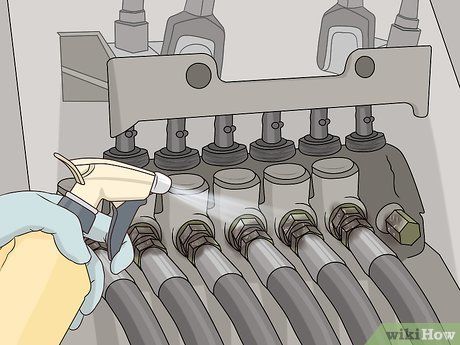

Cleanse Hose Connectors Thoroughly: Over time, dirt and grime accumulate on hose connectors, posing a risk of contamination upon removal. Before detaching the hose, apply window cleaner or similar solvent around the attachments. Subsequently, use a rag to wipe away any accumulated debris.

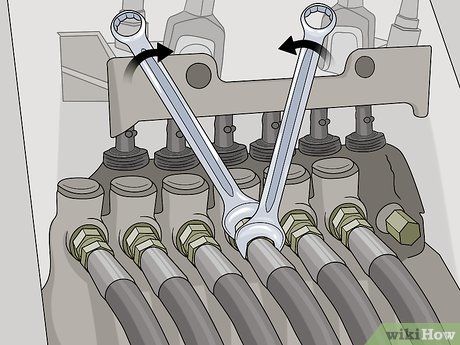

Utilize Dual Wrenches for Fitting Unscrewing: Hydraulic hoses are typically secured by fittings with opposing rotational directions. Secure the fitting closest to the hose with one wrench while loosening the attachment nearer to the machine by turning it counterclockwise with another wrench. Continue until the hose detaches from the fitting. Repeat this process for the opposite side of the hose.

- Choose wrench sizes according to hose specifications. Standard wrench sets offer various sizes suitable for most equipment. Experiment with different wrench sizes to find the appropriate fit for your hose attachments.

Installation Process of a New Hose

Acquire a Replacement Hose Matching the Original's Specifications: Given the diversity in hydraulic hoses, ensure precise compatibility by selecting a replacement hose identical to the original. Verify consistency in width, thickness, and pressure rating, typically indicated in psi on the hose itself.

- If uncertain, take the old hose to the store and seek assistance from staff to procure an identical replacement.

- Upon selection, request the supplier to cut and crimp the hose using specialized equipment, as home crimping is impractical.

- During crimping, the supplier will affix a new fitting to the hose's end, facilitating attachment to the machine's existing fitting.

Apply an Abrasion Sleeve to Prevent Wear: For hoses prone to contact-related wear, consider employing an abrasion sleeve. This protective fabric sleeve safeguards the hose from damage caused by friction against machinery or other hoses, potentially extending their lifespan.

- Abrasion sleeves are obtainable from hydraulic hose suppliers.

Cleanse Hose Fittings and Connectors Thoroughly: Pre-installation, ensure cleanliness of all hose connectors to prevent ingress of dirt or grime into the hydraulic system, which could lead to damage. Use a damp cloth to wipe down all connectors, removing any accumulated debris.

Secure One End of the Hose into the Fitting: Initial insertion of the hose end is straightforward since one side remains free. Insert the hose end into the fitting and rotate clockwise to tighten. Cease rotation once the hose stops spinning to prevent over-tightening, which may cause attachment rupture and subsequent leaks.

- Exercise caution to avoid excessive tightening, as snugness upon cessation of rotation indicates sufficient attachment. Excessive force may compromise the attachment integrity, resulting in leaks.

Utilize 2 wrenches for securing the final side. Securing the final side of the hose presents a challenge as it lacks rotational freedom. Insert the hose into the connector and stabilize it with one wrench. Utilize another wrench to rotate the machine-attached connector. Cease rotation once the connector reaches maximum tightness.

Restore any removed coverings post-installation. Ensure all components are correctly reinstated before hydraulic system testing. Refer to captured images or the owner’s manual for verification of correct placement.

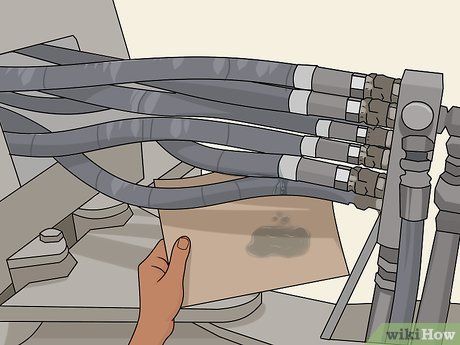

Conduct a Low-Pressure Hydraulic Fluid Circulation Test. Post-hose replacement, it's crucial to test the equipment. Initiate the machine, setting the hydraulic mechanism to low power. Inspect hoses for leaks by maneuvering a cardboard piece around them.

- Audible air escape signifies a leak; refrain from using equipment if air leakage is detected.

- In case of fluid or air leakage, halt machine operation, lower the mechanism, and release pressure. Reassess hose connections for proper tightening. If leaks persist despite tight connections, the hose may be defective; return it to the supplier.

- Upon confirming absence of leaks, slowly operate the hydraulic system to assess performance. Successful operation indicates a successful replacement.

Evaluating Hose Replacement Necessity

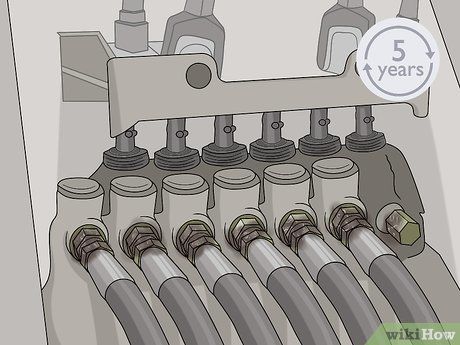

Renew Hydraulic Hoses Every 5 Years Post-Manufacture Date. Manufacturers typically imprint the hose's manufacture date for reference. For hoses under regular usage, replacement is recommended after 4 to 5 years, irrespective of visible wear. Even under light usage, hoses should be replaced after a decade to prevent aging-induced bursts.

- Even minimally used hoses should be replaced after a decade; rubber degradation over time poses bursting risks.

Conduct a Visual Inspection for Hose Wear or Damage. Hydraulic hoses deteriorate due to various factors such as stress, heat, sunlight, and regular usage. Assess the hose surface for indications of wear or damage. Replace any hose exhibiting signs of cracking, tearing, or abrasions. Immediate replacement is necessary for hoses with exposed support wires or those that are crushed or pinched.

- Visible wear signs encompass cracks, tears, and abrasions. In severe cases, the outer rubber may erode, revealing inner support wires. Such hoses warrant immediate replacement.

- Hoses subjected to crushing or pinching should also be replaced promptly.

Use Cardboard to Detect Hydraulic Fluid Leaks. Promptly replace hoses leaking hydraulic fluid. If dealing with multiple hoses, identify the leaking one by wiping them down to eliminate surface oil. Rub a piece of cardboard along the hoses; the presence of a wet spot indicates the leaking point, necessitating hose replacement.

- A specialized dye, designed for leak detection in hydraulic pipes, fluoresces under a black light, facilitating leak identification. This method is commonly employed in industrial settings. To utilize this technique, inject hydraulic dye into the system and inspect hoses under a black light to identify leaks.

Valuable Advice

-

Always consult your equipment manual for precise replacement guidelines, as protocols may vary between different machinery.

Important Cautions

- Always wear protective gloves when handling hydraulic fluid.

- If you're uncertain about replacing hydraulic hoses, consider hiring a professional for the task.

- Immediately seek medical assistance if exposed to hydraulic fluid on your skin; untreated exposure can result in severe damage.

Essential Supplies

- Wrenches

- A replacement hose

- A container or cloth for oil containment

- Protective gloves and goggles