The table is a central piece of furniture in any RV or camper. It serves as a gathering spot for socializing, dining, and entertainment during your travels. However, the RV table often lacks stability, leading to wobbling or breakage. This is commonly due to inadequate support from a single bracket, known as a pedestal mount. Fortunately, addressing this issue is relatively simple. You can stabilize a wobbly table by adjusting the pedestal mount or replacing it with a reinforced version. Additionally, installing an extra support beam can help distribute weight and prevent future wobbling.

Steps to Follow

Fixing a Unstable RV Table

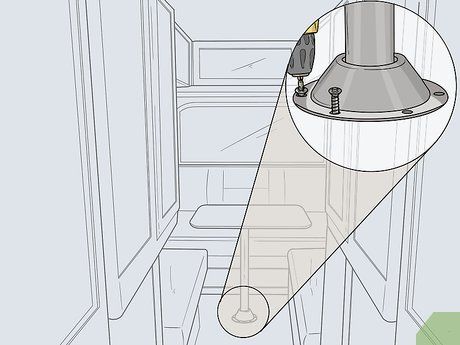

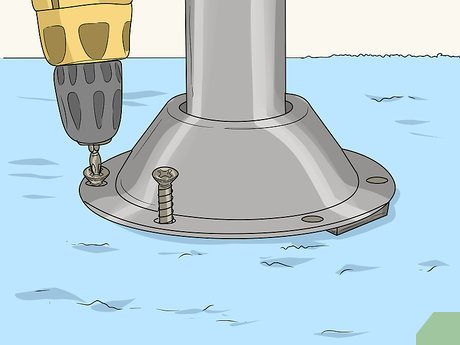

Adjust the screws securing the pedestal mount around the base of the table leg. Loosening these screws using a drill or screwdriver allows for leveling the mount and adding shims to reinforce it. If the screws are too tight or if the mount appears loose, consider replacing the screws with slightly longer and larger ones for better stability. Plan for around 15-20 minutes to stabilize your table effectively.

Pro Tip: If your pedestal mount and table seem loose but nothing is visibly wrong, try this method. Often, the pedestal mount wobbles because it isn’t flush against the floor or the table is uneven.

Level the tabletop manually. Place a spirit level horizontally on the table. Hold the edge of the tabletop and slide it until it’s flat. Once level, rotate it 90 degrees to ensure evenness on both sides. Continue adjusting until the table is perfectly flat.

Use shims to stabilize the pedestal mount. Get wood shims and place them between the mount and the floor. Add shims to the side opposite the tilt until the mount is stable. For example, if the table tilts to the right, shim the left side.

- If needed, gently tap the shims with a rubber mallet.

- To fill gaps, place shims over screw slots.

- If still wobbly, insert shims over screw slots.

Reinstall the pedestal mount screws. Use the original or slightly larger screws to secure the mount. Drill screws through the slots to attach it to the floor. Be cautious drilling through shims to prevent wood damage.

- Drill slowly through shims covering screw slots.

Strengthening a Weak Pedestal Mount

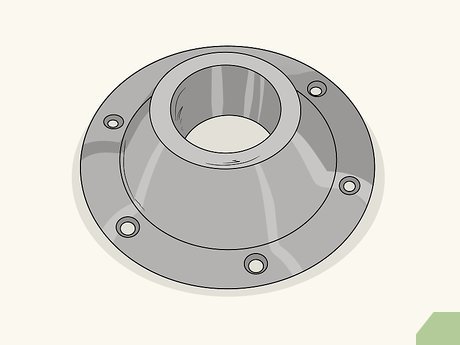

Order a replacement pedestal mount from your RV manufacturer. If your RV table wobbles but the mount is secure, get a replacement from the manufacturer. Contact them directly to place an order.

- If it’s an aftermarket table, contact the table manufacturer.

- Allow at least 24 hours for drying time after installation.

Pro Tip: If your pedestal mount seems stable but the table leg wobbles, try this method. It's common with cheaper mounts or if the mount's rim is bent.

Sand the interior of the replacement mount with fine sandpaper. Turn the replacement mount upside down and sand the inside with 200-300 grit sandpaper. Roughen the surface to ensure better bonding with the compound.

- Imagine the mount like a hollow donut. You'll reinforce it with compound, similar to rebar in concrete.

Mix cold weld compound thoroughly. Wear gloves and mix the compound from two tubes until it's gray. This compound bonds metal and needs proper activation before use.

- Cold weld compound is available in construction stores.

- You'll need about 1 ounce (28 g) of compound for this.

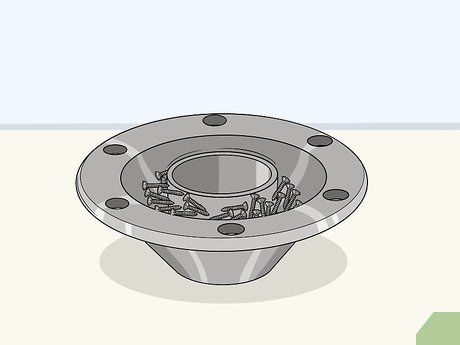

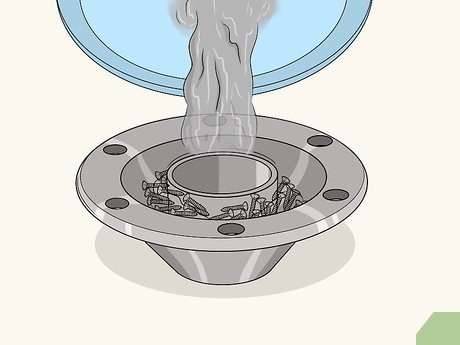

Fill the pedestal mount interior with loose wood screws. Invert the mount and add 15-20 wood screws evenly inside. They don't have to be perfectly flat as they'll be hidden when the mount is installed.

- Adjust screws by hand if desired for a cleaner look.

Fill the pedestal mount with cold weld compound. Use an expired gift card or cardboard to pour the epoxy into the mount. Ensure even distribution along all sides.

- It should resemble a small pool around the mount.

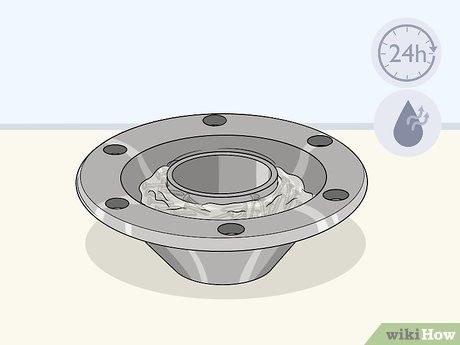

Allow the compound to dry for 24 hours. Cold welding compounds typically need at least 12 hours to dry. For a thick layer like this, give it a full day to set.

- Keep windows open to avoid odors.

Remove the old mount and lift out the table. Unscrew the support screws holding the old mount. Lift the table out and dispose of the old mount. You can reuse the screws if desired.

- Rarely heavy, so lifting should be easy.

- If there's a hinge, unscrew it too.

Install the new mount and reattach the table. Place the new mount and align the screw slots. Secure it with the old screws. The table can now be reinserted, providing sturdiness with the filled mount.

- The filled mount ensures durability.

Enhancing Support with an Extra Beam

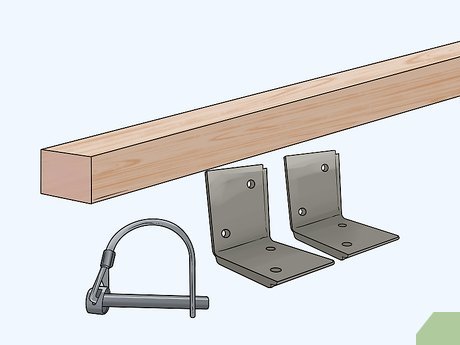

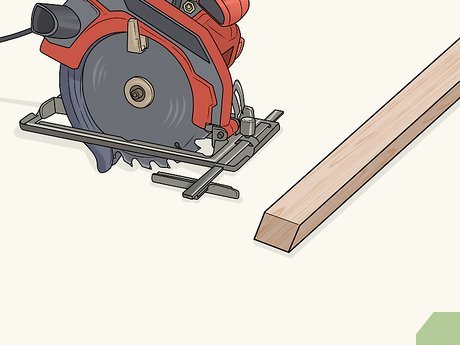

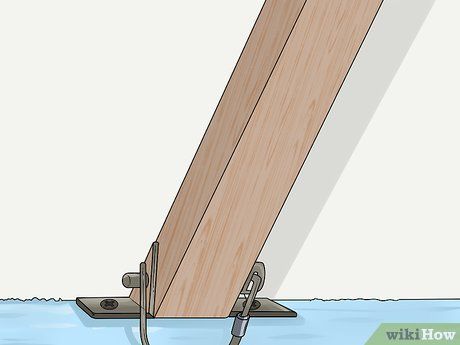

Acquire a 2 by 2 inch (5.1 by 5.1 cm) hardwood piece and 4 L-brackets. To reinforce your table with an extra leg, buy a 2 by 2 inch (5.1 by 5.1 cm) hardwood piece at least 80 inches (200 cm) long. Also, purchase 4 L-brackets, which are L-shaped supports for furniture and shelving.

- This support beam will stabilize vertical legs, acting like a tripod.

- An 80-inch (200 cm) piece can make 2 support beams, useful for mistakes.

- This task will take 2-4 hours, depending on your saw skills.

Tip: Opt for this if your table is generally fine but you want to prevent future issues.

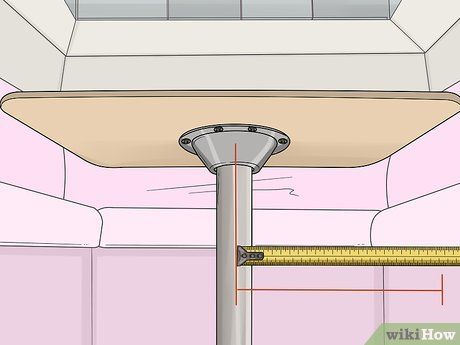

Measure from table center to wall corner underneath. Use a measuring tape to mark the distance from table center to wall corner underneath.

- You can place the beam slightly off-center if preferred.

Cut wood with 45-degree angles on each end. Wear safety gear and cut wood with a saw. Make 45-degree notches on marked ends to create flat platforms.

- Cuts should be symmetrical.

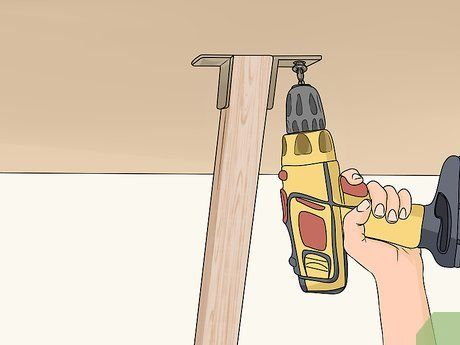

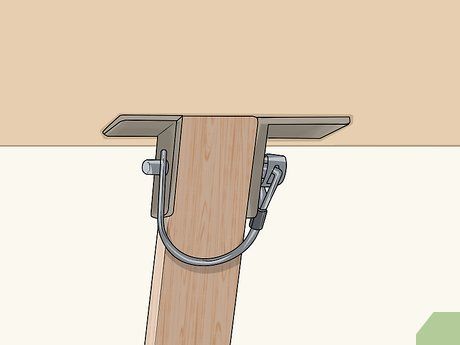

Attach 2 L-brackets to the top of the wood. Position brackets flush with the cut edges and secure with wood screws. Install symmetrical brackets on the opposite side.

- Ensure brackets are aligned with the cuts.

- Result: 2 metal tabs protruding from the beam's top.

Attach 2 more brackets at the support beam base. Repeat the process on the other end. Drill L-brackets into the beam so they align with the bottom cut. Each end should have 2 brackets.

- Ensure brackets sit flush.

Secure top brackets to table bottom with wood screws. Position the beam under the table, aligning top brackets with the table bottom. Attach with 1 in (2.5 cm) wood screws.

- Use smaller screws for thinner tables.

- Beam should form a 45-degree angle with the table and nearby wall.

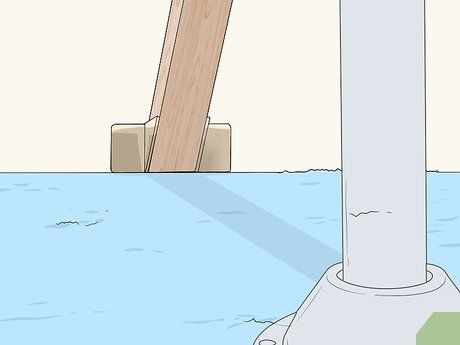

Fasten brackets near the wall to the floor. Use 1.5 in (3.8 cm) wood screws to attach brackets to the floor. This secures the beam, providing stability and preventing sliding.

- You can add a second beam for extra support.

- Ensure beam is flush with floor and table.

Helpful Hints

Warnings

- When using a power saw, always wear protective gear: eyewear, gloves, and a dust mask. Keep hands at least 6 inches (15 cm) from the blade during cutting.

Essentials

Fixing a Wobbly RV Table

- Drill

- Spirit level

- Wood shims

Strengthening a Weak Pedestal Mount

- Replacement pedestal mount

- Screws

- Cold welding compound

- Straight edge

- Gloves

- Drill

Enhancing Support with an Extra Beam

- Wood beam

- L-brackets

- Measuring tape

- Carpentry pencil

- Screws

- Protective eyewear

- Dust mask

- Sawhorses

- Gloves

- Circular saw or handsaw

- Drill