Fuel pump systems aren't just in Vietnam, but worldwide they operate in a similar fashion: Drawing fuel from reservoirs and pumping it for customers, then replenishing the reservoirs to a certain level. Recently, notices of fuel shortages have surfaced, indicating the reservoirs aren't at their usual levels and require gradual refilling to manage remaining fuel.

Or perhaps the fuel pump stands aren't functioning at full capacity. Similar to slow charging, it could be due to electrical issues or insufficient power.

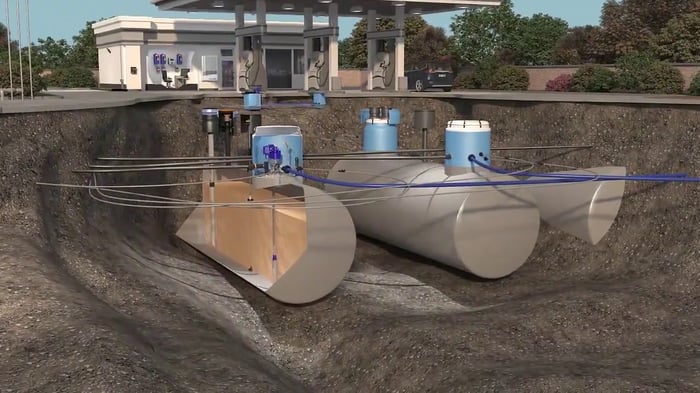

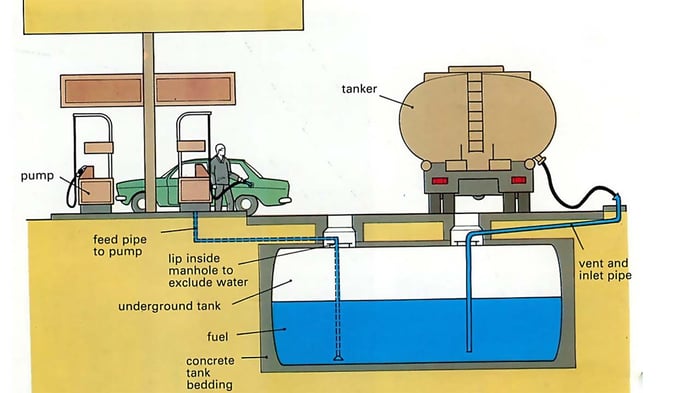

At every gas station, beneath the ground lies a tank ranging from 25 cubic meters, featuring multiple layers of insulation, moisture absorption, impact resistance, and more to protect the fuel tanks. Typically, larger stations have two to three tanks to ensure adequate supply for most pump stands.

Fuel is pumped from underground reservoirsIn order to transport gasoline from the underground tank up to the pump for refueling, gas stations need to equip themselves with pumping systems. Currently, there are two types of pumps in use: Submersible pumps and suction pumps. Submersible pumps are pump machines placed inside the gasoline tank, submerged in the fuel and utilizing a pump fan system to push the gasoline up through the suction hose.

Suction pumps make use of pressure differentials to pump gasoline up through the suction hose. The system consists of a pipe placed inside the fuel tank, a motor positioned on the surface of the fuel to draw air out of the suction tube just enough to create sudden pressure changes. The weight of the surrounding air forces the gasoline up the suction tube, which was previously filled with air. This functions much like when we suck on a straw.

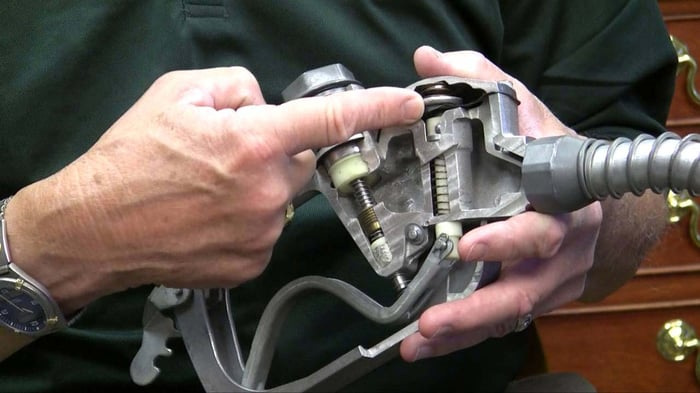

After gasoline is drawn from the tank, it travels along the fuel line towards the pump nozzle, where it is dispensed when the trigger is squeezed to open the release valve. Similar to how indoor water faucets draw water from the tank and pump it, just a simple squeeze of the nozzle releases the gasoline.

Not only stopping at functioning like water faucets, gasoline pump nozzles are also equipped with a mechanism to prevent gasoline from flowing back into the tank. In other words, the tank can only pump in one direction, while any excess gasoline after refueling is stored in the fuel line and locked by a Check Valve. This valve is placed at the end of the fuel line; when closed, it creates a suction pressure at the nozzle end to keep the gasoline in the line, preventing any leakage, similar to how you block the end of a straw in a glass to keep the water inside even when not sucking it up.

Ensuring gasoline doesn't flow back into the tank primarily serves to protect the gasoline pump system and optimize refueling speed for the next customer, as the gasoline is already in the line and ready to dispense with just a squeeze, eliminating the need to wait for pumping from scratch. Allowing gasoline to flow back in poses risks including dirt from the outside, affecting overall gasoline quality and posing a threat to the pump engine.

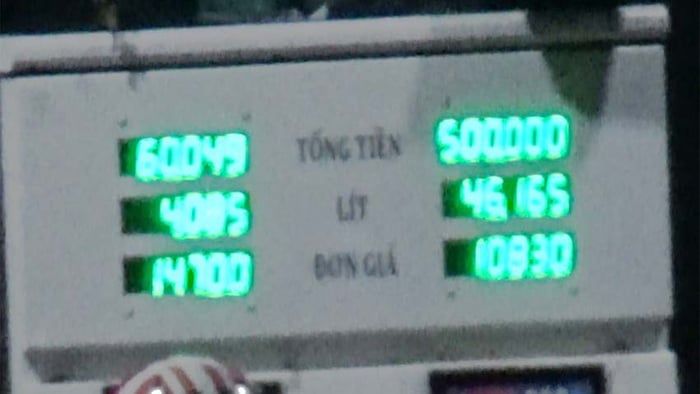

If gasoline isn't stored in the pump stand, then what's the pump stand for?The essence of the pump stand is merely to hold the gasoline hose and display the pumped amount of gasoline along with the price. At the pump nozzle, there's a component called the flow meter, attached at the junction between the gasoline hose and the nozzle, to measure the flow rate. It's typically made of iron or aluminum, housing a simple rotor component to calculate the gasoline volume passing through.

The calculated gasoline volume is then passed through a digital counter and displayed on the stand. This counter not only shows the number but also compensates for ambient temperature to provide the most accurate gasoline volume for customers. For those attempting to 'hack' the gasoline volume, they might install a circuit capable of 'adjusting' the counter to display inaccurately.

Furthermore, the gasoline pump nozzle includes a gasoline flow control component to prevent overfilling, which could lead to spillage. This component is a small tube inside the main nozzle pipe; when the tank reaches full capacity, gasoline will overflow into the small tube, triggering a pressure change that activates a relay inside the gasoline pump nozzle, causing the gasoline pump valve to automatically shut off, preventing further spillage.

The complex structure of the gasoline pump nozzle

The complex structure of the gasoline pump nozzleIt can be seen that the gasoline pump stand, despite its simple appearance, serves various purposes to ensure a safer and more convenient refueling process. There are notable similarities between a phone charger and a gasoline pump stand, both facilitating energy transfer and controlling flow when supplying vehicles/phones.

- Explore more articles in the Discover category