Most issues with an electric fan, such as blades not spinning or excessive noise, typically stem from inadequate lubrication or vent blockages. To address these problems, disassemble the fan, apply lubrication to the central pin and bearings, and thoroughly clean the vents and motor casing. Repairing an electric fan can pose challenges, especially if the motor itself is faulty. Signs of a dead motor include complete silence when the fan is turned on and blades failing to rotate even after cleaning and oiling. Given the affordability of electric fans, attempting to repair a malfunctioning motor may not be worthwhile, and purchasing a new fan may be the better option.

Procedures

Dismantling the Fan

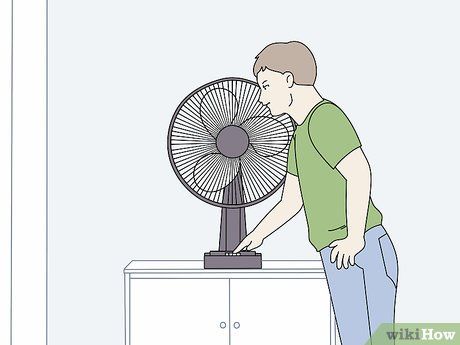

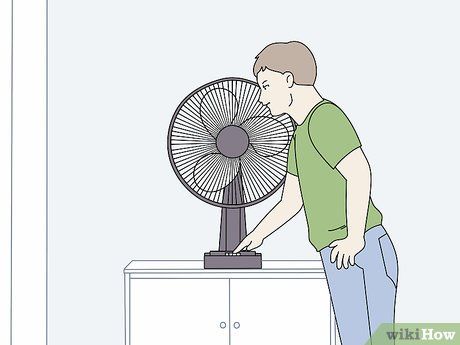

Verify the functionality of the fan's motor. Plug in the fan and set it to its highest speed. If the blades exhibit any movement or the fan begins to rotate, it suggests the motor is operational. If there's no audible sound, listen closely behind the blades' central area. Toggle the fan off and on, paying attention to any motor sounds. The presence of humming or buzzing indicates the motor is likely functioning.

- Test the fan across multiple power outlets. A tripped circuit breaker could have disrupted the electrical signal to the fan.

Hint: Attempting to revive the engine of most table and standing fans is usually futile; chances are the motor is beyond repair. It's advisable to invest in a new fan if the motor fails to start. However, if you're determined, you can disassemble the motor and try fixing it yourself!

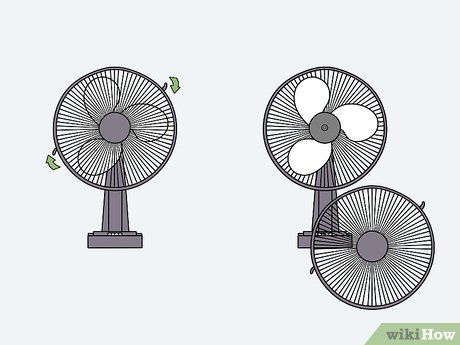

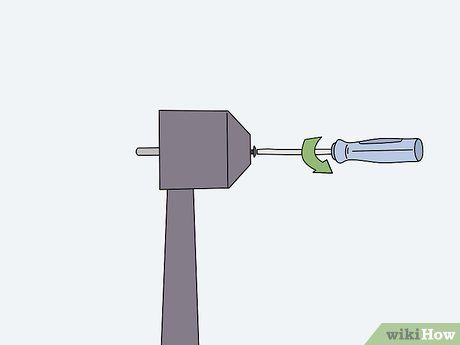

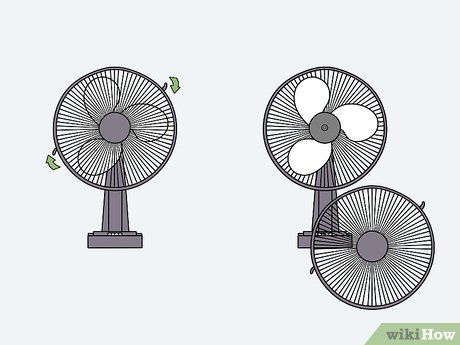

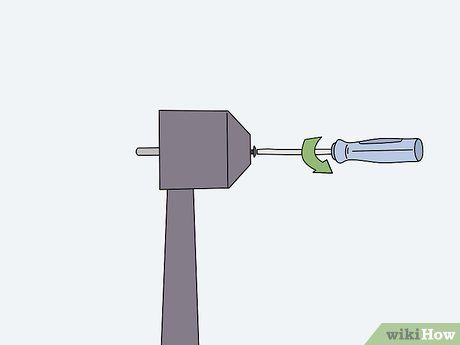

Disconnect the fan from power and dismantle the blade guard or loosen the pin. Pull out the fan's power cord to prevent accidental activation during maintenance. Search for clips along the edges of the blade guard holding its parts together. If clips are present, release them and detach the front section. In the absence of clips, turn the central circular component of the fan counterclockwise. If it loosens, unscrew it and place the front part of the blade guard aside.

- The pin serves as the central axis for the rotation of blades and the casing.

- The blade guard, also known as the blade casing, prevents injuries from the blades. It's typically secured with clips or a central cap.

- If screws secure the casing, use a screwdriver to remove them for disassembly.

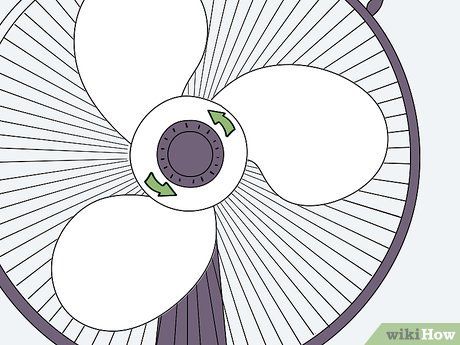

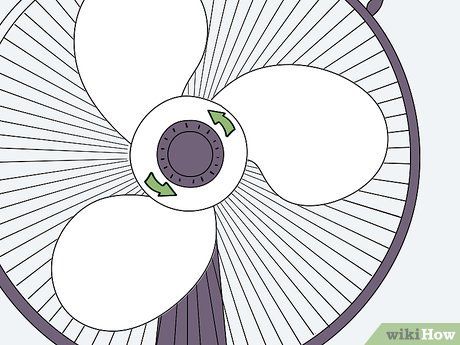

Rotate the blades or the central washer counterclockwise to detach them. The method varies for each fan, but typically, a small washer secures the blades on the pin or the pin casing itself. If there's plastic obstructing the center of the blades, twist it counterclockwise until it disengages, then slide off the blades. If there's no washer, hold the pin in place and twist the base of the blades counterclockwise to remove them.

- Some fan models feature a latch on the pin's side to lock or unlock the blades.

Remove the rear part of the blade guard from the central pin. First, eliminate any plastic or metal washers in front of the rear blade guard section. You might need to unscrew certain screws to access this part. Take off any washers and slide the rear blade guard section entirely off the pin.

- If a plastic washer was in front of the blades, there might be none in the rear. Conversely, if there was no plastic washer in front, it's likely present at the rear, acting as a stabilizer for the blades.

- If there's a plastic cover obstructing the motor's body, unscrew the plate to access the motor.

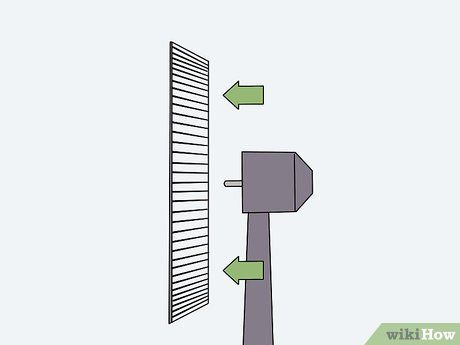

Turn the fan around and locate the screws at the back. With the front motor and pin mostly visible, flip the fan to inspect the rear side of the motor casing. Most fans have a plastic vent for heat dissipation. This vent is held in place by screws at the back. Use a flathead or Philips screwdriver to remove these screws. Set them aside and pry off the casing.

- After unscrewing, the casing may come off easily. If not, insert a screwdriver into a vent and gently pry it out.

- In some table fans, the motor might be situated beneath the base. If there's no bulky component behind the blades and the base is wide, unscrew the fan's bottom and remove the plastic cover.

Oiling the Bearings

Rotate the front pin of the fan manually to check its movement. Use your hand to turn the central pin of the fan. If it feels stiff or resistant, it likely requires lubrication. Continuous rotation of the fan blades leads to the wearing down of the pin's lubricant over time. Applying oil to the pin typically resolves this issue.

- A dry or sticky pin often causes blade movement issues.

- If the pin turns easily and there's no resistance, switch on the fan to verify if the pin rotates. If it doesn't, the issue likely lies with the motor, indicating a potential short circuit. In such cases, replacing the fan might be more practical.

Remove any washers or bolts obstructing the base of the pin. Once the pin is accessible, there may be 1-2 metal bolts securing it to the fan frame. Utilize a wrench to loosen and unscrew these bolts. Complete removal isn't necessary, but sufficient clearance is required to access the entire pin.

- If there are no washers or bolts, proceed to the next step directly.

- Washers in this part of the fan assembly can usually be loosened manually.

Apply lubricant to both the front and back of the pin. Obtain a bottle of lubricating oil with a narrow pouring nozzle. Place a clean cloth beneath the pin to catch any dripping oil. Position the bottle over the front part of the pin where it connects to the motor frame and gently squeeze to apply oil. Adjust the bolts to access both sides of the pin for lubrication.

- Any type of lubricating oil is suitable for this task, readily available at automotive or hardware stores.

- If desired, wear rubber gloves to prevent oil from contacting your skin. Although non-toxic, it's easily removable with soap and water.

Caution: Ensure thorough oil coverage on the pin while avoiding spillage onto the motor. If excess oil is visible, use the cloth to absorb it.

Rotate the lubricated section of the pin while spinning the bolts around it. After fully lubricating the pin, reposition the bolt in place. Place a cloth underneath and hold the bolt with your non-dominant hand. With your dominant hand, grasp the pin. Move the bolt back and forth over the lubricated area while manually rotating the pin. Repeat this process for any bolts on the opposite side of the pin assembly.

- This ensures that the bolts, responsible for securing the pin, are adequately lubricated during rotation. Without proper lubrication, friction may hinder the pin's movement.

- If preferred, you can remove and oil the bolts separately.

Cleansing the Motor and Ventilation

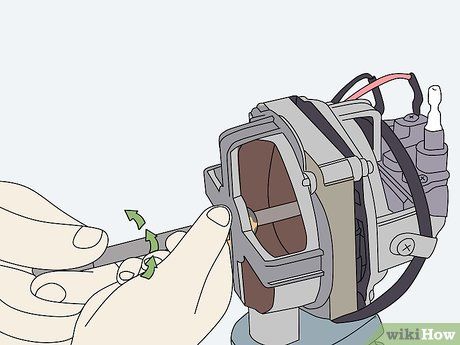

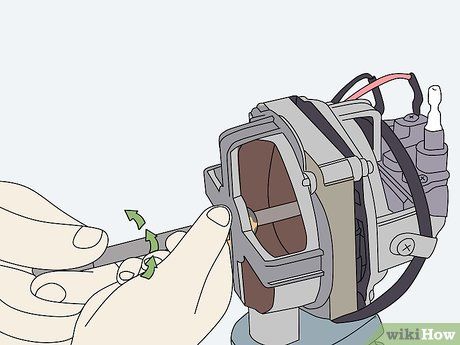

Examine the rear section of your motor casing for dust or dirt accumulation, then wipe it off. Flip the fan and inspect the interior of the casing surrounding the motor. Employ a clean microfiber cloth to meticulously remove accumulated dust. Ensure thorough cleaning around the entire interior to eliminate any accumulated dust and dirt.

- Inadequate ventilation can lead to dust and heat buildup inside the motor casing, potentially causing the fan to malfunction—particularly if it features an overheating mechanism triggering automatic shutdown.

Caution: Avoid using water to clean the motor area. Contact with water could result in electrical shorts or damage to your fan.

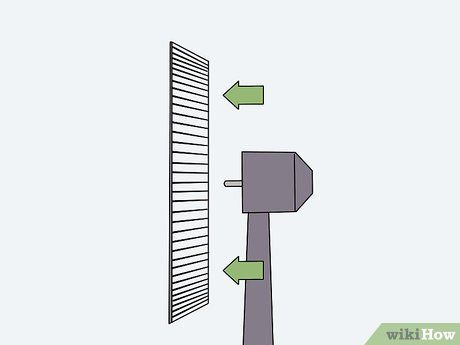

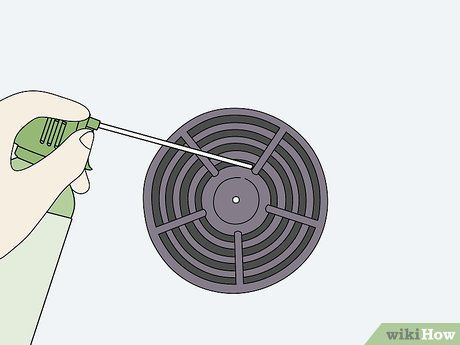

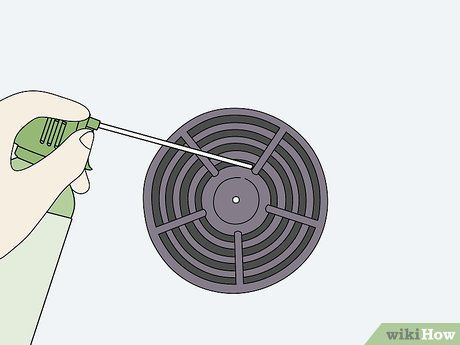

Utilize compressed air to clean the plastic vent on the rear side. Take the previously unscrewed vent cover, holding it away from the motor. Use compressed air to blow out dust from both sides of the cover, reaching into the narrow spaces between the vent's bars. Afterward, wipe the cover with a dry cloth.

- If the vent is heavily clogged with dust or debris, it could be impeding your fan's performance.

- For thorough cleaning, soaking the vent in water and soap followed by air drying may be considered, although usually unnecessary.

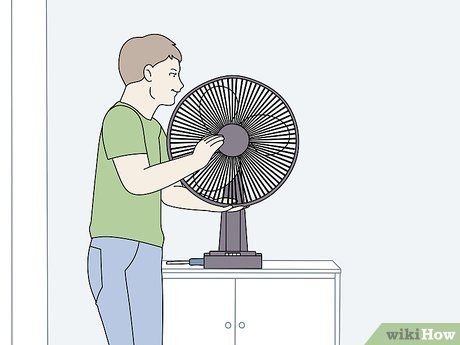

Plug in your fan and switch it on to check if the pin rotates. Before reassembling the fan, plug it in and turn it on to observe the pin's rotation. If the pin spins smoothly, proceed with reassembly. If not, you may need to

clean the motor. However, this can be a complex task, especially for budget-friendly fans, often not worth the effort.

- Many standing and table fans lack a removable motor, making cleaning or adjustment challenging.

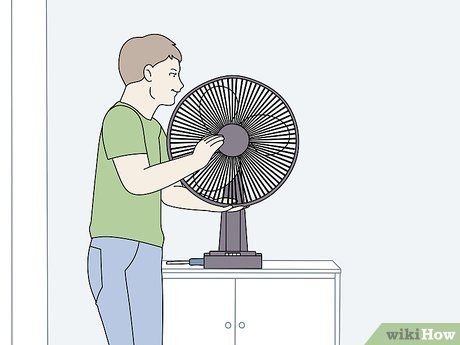

Reconstruct your fan by reattaching the blades, bolts, and casing. Follow the reverse order of disassembly. Use a wrench to tighten the bolts on the pin and replace any washers before sliding the blade guard over the pin. Position the blades so that the rear blade guard separates them from the motor. Reattach the plastic vent to the back of the motor casing and screw it in place. Finally, secure the front blade guard and lock it.

- After turning the fan back on, if the blades spin slower than the pin during testing, it indicates a failing motor. It's operating at insufficient power to drive the fan fully.

Pointers

Essential Tools

Dismantling the Fan

Oiling the Bearings

-

Lubricating oil

-

Wrench

-

Cloth or towel

Cleansing the Motor and Ventilation

-

Microfiber cloth

-

Compressed air

-

Screwdriver

-

Wrench