Repairing an electrical cord or plug is simple and safe

Whether your cords endure foot traffic or become chew toys for pets, they inevitably wear out over time. Replacing them can be costly, but fear not, most cords can be repaired inexpensively. Begin by cutting off the damaged section. For a quick fix, replace the plug entirely. If preserving cord length is a priority, soldering the wires with metal solder offers a durable solution. Finally, test your repaired cord to ensure it functions like new.

Essential Information

- Trim away the damaged section of the cord, then splice and align the wires, ensuring color or ridge matching.

- Protect the repaired area with a PVC shrink tube and shrink it using a heat gun.

- Choose a plug with the same specifications as the original. Connect the hot wire to the gold screw, the neutral to the silver, and the ground wire to the green screw.

Procedure

Identifying Wire Damage

Disconnect the cord from the power source. Ensure it's completely unplugged before handling. Even when disconnected, residual current may still be present. Avoid contact with exposed wires or contacts. Disconnect any other devices or appliances linked to the cord.

- If dealing with severely damaged cords, consider shutting off the electricity first. Locate the fuse or circuit breaker, typically found in a secluded area such as the basement or storage room.

Examine the cord for fractured wires and other indications of harm. Run your hand along the entire length to check for unusual warmth. Look for breaks in the insulation that may hinder functionality. Additionally, inspect the plug prongs for signs of melting or burning.

- Consider marking damaged areas for easy identification later.

- If extensive damage is observed, it may be preferable to purchase a replacement cord rather than attempting repair.

- Note: Broken extension cords cannot be safely spliced back together. Regardless of reconnection efforts, the cord will remain unsafe for use. Instead, replace the plug.

Mitigate surface damage by encasing it in electrical tape. Place the tape's edge over the broken section and wrap it around the cord several times to seal the damage. Ensure a secure seal and treat other affected areas similarly. Electrical tape, a form of black vinyl resistant to electricity, is ideal for cord wrapping as long as no exposed wires are present.

- If frayed metal is visible due to severe damage, cutting and repair may be necessary. Tape serves to insulate wires and prevent exacerbation of existing superficial damage.

- An alternative is fitting a PVC shrink tube over the damaged section, gently heating it to seal the break.

- While other tapes like duct tape may suffice, electrical tape is preferred due to its design for electrical applications.

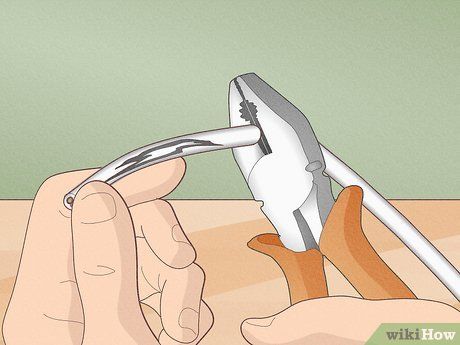

Use pliers to sever the cord on both sides of the damaged area. Employ end-cutting or lineman’s pliers for clean cuts. Position the pliers beyond the damage and cut through the cord, insulation, and wiring in a single motion. Repeat on the opposite side to fully remove the damaged segment.

- Assess the length of each remaining section. If sufficiently long, both sections may be reusable. Discard excessively short lengths.

- For instance, a severed extension cord may yield two usable parts. Smaller cords, such as those from electronic devices, may not require the shorter segment even if reusable.

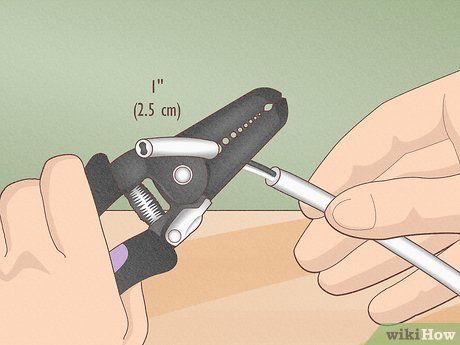

To strip about 1 inch (2.5 cm) of insulation from the cord, employ wire strippers. These tools are ideal for removing the outer casing of the cord without causing damage to the wires beneath. Measure from the cut end of the wire, ensuring not to remove more insulation than necessary. Apply pressure with the pliers to break the insulation and then slide it off the wire. Repeat this process for the other half of the cut cord if you intend to solder the pieces back together.

Eliminate the insulation from each wire within the cord. Measure approximately 3/4 inch (1.9 cm) from the cut end of each wire. Utilize wire strippers to penetrate the casing. Remove the cut insulation to expose the copper wires, which can then be rerouted to your replacement cap.

Installing a New Plug

Choose a new plug with the same number of prongs as the old one. If you're fixing a cord without soldering, installing a new plug is necessary. Ensure the new plug matches the old one in shape, prong number, and amp rating.

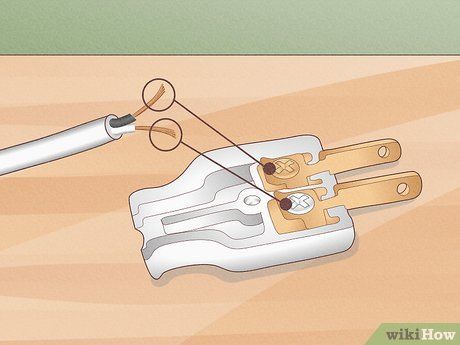

Examine the replacement cord cap for labels indicating where each wire should be inserted. Cord caps feature slots with screws to hold the wires in place. These slots may be labeled to correspond with the wires inside the electrical cord. Match these labels with the color of the insulation on each wire.

Wrap the exposed wire ends clockwise around the screws. Connect each wire to the appropriate cap terminal one at a time, ensuring they're securely twisted together before wrapping them around the screws. Utilize the small notches on most plugs to hold the wires close to the screws.

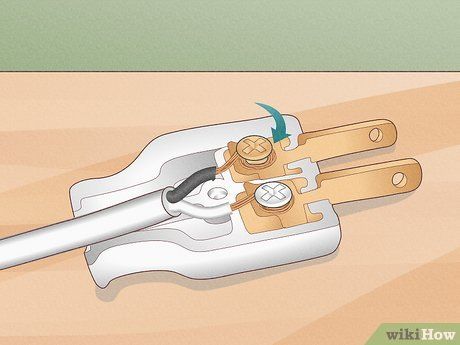

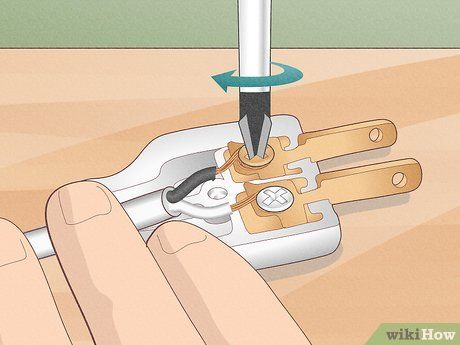

Tighten the screws clockwise to secure the wires to the cap. Use a Phillips screwdriver to tighten each screw. Double-check the positioning and security of the wires before proceeding. If adjustments are needed, loosen the screws by turning them counterclockwise.

Slide the plug housing over the cap and screw it into place. Place the other half of the plug onto the cap, ensuring the wires are well-protected. Look for a small hole on the outside of the housing where you can insert a screw. Tighten the screw clockwise, being careful not to overtighten it.

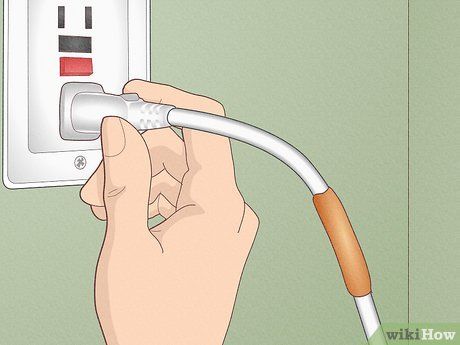

Test the cord by plugging it into a working outlet. Before testing, deactivate power to the outlet and surrounding area. Once ready, activate the power and observe for any unusual signs. If all seems well, the repair was successful! If issues arise, immediately deactivate power and investigate further.

Splicing Wires

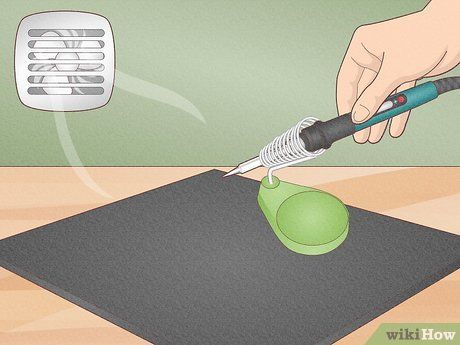

Prepare a well-ventilated and heat-resistant workspace. Ensure your workspace has adequate ventilation, such as a ventilation fan or open windows. Use a fire-safe surface like stainless steel or ceramic to prevent burns from the soldering iron. Alternatively, spread a heat-resistant material like a glass soldering mat for protection.

Slide a PVC shrink tube onto the wire for later use. Choose a PVC shrink tube of appropriate size to protect and insulate exposed wires. Slide it along one of the cords, leaving the stripped wires exposed for repair.

Opt for 63/37 lead solder for easier handling. This type of solder consists of 63% tin and 37% lead, melting at a low temperature for a strong fix. It's beginner-friendly and commonly used for electronic repairs.

Wear protective gear, including safety glasses. Prioritize safety by wearing safety glasses to shield against splashes from the soldering iron. Consider wearing long-sleeved clothing and closed-toe shoes for additional protection.

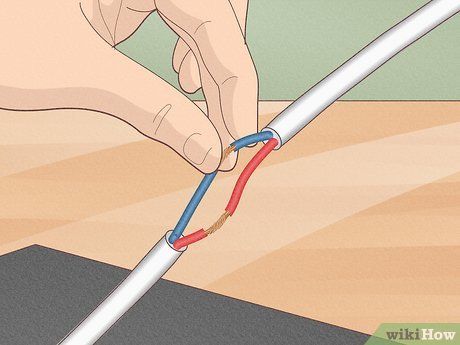

Twist the exposed ends of the internal wires together. After cutting and stripping the damaged portion of the cord, match the wires according to their insulation color. Twist the wires together, ensuring proper separation of colors to prevent short-circuiting.

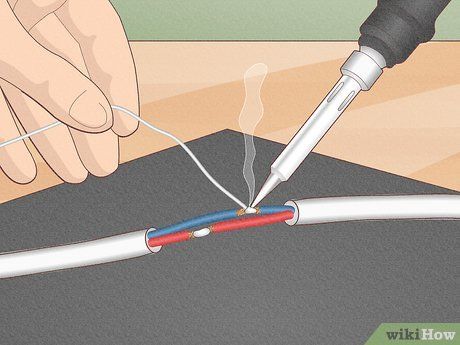

Apply solder to cover the wires. Position the solder wire at a 45-degree angle above the wires, and the heated soldering iron at the opposite 45-degree angle. Melt the solder onto the exposed wires, ensuring they're evenly coated.

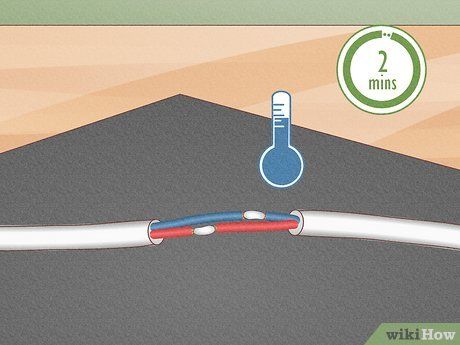

Allow the soldered wires to cool for approximately 2 minutes. Avoid disturbing them until they've cooled completely. Turn off the soldering iron and set it aside safely during this time.

Gently heat the PVC tube after placing it over the solder. Position the tube over the repaired area and use a hair dryer or other gentle heat source to shrink it tightly over the soldered section.

Test the cord by plugging it into an outlet. Turn off the power, then plug in the cord and reactivate the electricity. Watch for any signs of trouble such as smoke. If all seems well, consider the repair successful.

Tips

-

If you have a long cord, consider cutting it into smaller cords. Discard short lengths left after cutting if they're damaged.

-

You can check cords using a continuity tester or multimeter. Look for a continuity of 0 ohms to ensure the repaired cord is functioning correctly.

-

Always ensure you're using the correct plug for the cord being repaired to avoid electrical damage to the wires.

Warnings

- Working with electrical wires poses risks of electrical shock. Take necessary safety precautions and avoid handling live wires.

- Splicing extension cords is considered unsafe according to the National Electrical Code. Repairs should involve cutting out damaged sections and replacing the plug.

- Do not attempt to repair external cords by twisting wires together, using wire nuts, and covering with electrical tape. While suitable for internal wire splicing, this method doesn't adequately insulate external cords against fires or electric shock.

Things You’ll Need

Cutting and Exposing Damaged Wires

- Tools such as wire cutters, pliers, or a utility knife

- Wire strippers

Installing a New Plug

- A wire plug

- A Phillips screwdriver

Splicing Wires by Soldering

- A PVC shrink tube

- 63/37 lead solder

- A soldering iron or pencil

- A heat gun, blow dryer, or lighter