When it comes to mixing plaster for sculpting, precision isn't necessary. Sculptors typically rely on a 'rule of thumb' approach for small to moderate amounts of plaster (less than five gallons/22 liters) used in molding and casting. This method applies to various standard gypsum plaster products like Plaster of Paris, Hydrocal, and Densité.

Steps

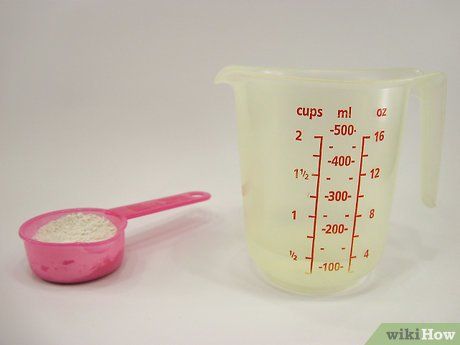

Determine the Quantity of Plaster and Silica Needed for Your Project. Remember, it's a 1/3 plaster, 1/3 silica flour, and 1/3 water mixture. While experience plays a significant role here, beginners may need to estimate and prepare extra to ensure they have enough. Common sense is key.

Pre-blend Plaster and Silica Flour.

Pour lukewarm, clean water into a flexible mixing container. A standard two-gallon (7.5 liter) plastic bucket works well. The water volume should be around one-third of your estimated total plaster/silica mixture from Step 1.

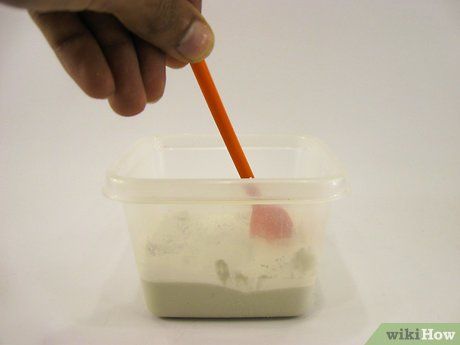

Combine dry plaster and silica with the water. Slowly sift the powder through your fingers to break up clumps, allowing it to fall into the water. Work swiftly but avoid dumping the plaster directly into the water. Do not stir the mixture yet.

Gradually add more plaster/silica to the water. Observe as it sinks slowly, with some powder remaining on the water surface. Distribute additional plaster to areas with standing water.

Stop adding plaster/silica once there's no more standing water. The surface should appear predominantly grayish with some white dry powder spots. Do not mix it yet!

Allow the bucket to rest for a few minutes. Utilize this time for final project preparations. If you're molding or casting, ensure you've properly applied the release agent to your pattern or mold.

Avoid hand-mixing plaster. Plaster generates heat during chemical reaction with water, posing a burn risk. Instead, use a wooden spoon or similar tool, employing a side-to-side motion akin to an exaggerated 'hello' wave.

Ensure to eliminate any lumps. Once thoroughly mixed, the plaster is ready for your project's use.

Tips

- Water temperature affects plaster setting time; hotter water accelerates, while colder water decelerates. Adjust according to project needs for faster or slower curing.

- Plaster may dry out skin; consider applying hand lotion post-mixing. Almond oil or standard moisturizers work well.

- Various mixing methods are acceptable, but avoid introducing air bubbles, which can harm mold or casting surfaces.

Warnings

- Avoid getting plaster on clothing or valuable items, as it's challenging to remove from fabric and porous surfaces. However, if spillage occurs, attempt to clean it instead of considering the item ruined.

- Always wear a dust mask to prevent inhalation of plaster dust particles, which can harden in the lungs and pose a serious health risk.

- NEVER use hands to handle plaster or apply it directly to skin—severe burns leading to amputation have been reported.

- Never dispose of plaster down drains, as it can solidify and damage plumbing. Dispose of unused plaster in the trash and rinse hands in a bucket of water before washing them.

Things You'll Need

- Plaster (dry powder)

- Clean water source

- Plastic bucket or flexible mixing container

- Project requiring mixed plaster