Bicycle wheel bearings are critical for minimizing friction and maintaining smooth rotation of the wheels. If your ride is feeling unstable or rough, it might be time to look at replacing those bearings. This maintenance requires both time and specific tools. Bearings come in two main types: ball and cartridge. Bikes with a screw-off skewer typically use ball bearings, whereas those with removable axle caps are likely to have cartridge bearings. Ensure you follow the correct procedure for your bike's bearing type.

Detailed Replacement Procedure

Revealing the Ball Bearings

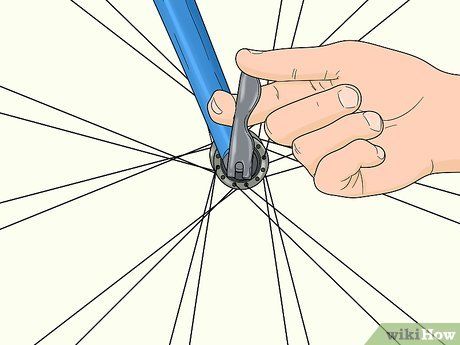

Detaching the Wheel: Modern bicycles often come with a quick-release lever on each wheel for easy removal. Simply lift this lever on the axle side to release the wheel and slide it from its housing. For bikes without quick-release, you'll need a wrench to unscrew the axle's nut before wheel removal. Remember to store any removed nuts safely to avoid losing them. Additionally, when taking off the rear wheel, ensure the chain is disengaged from the freewheel to facilitate the removal process.

Detach the skewer from the axle's center: Lay the wheel on a flat surface, with either side facing up. Grip the bottom end of the skewer and turn the top nut counterclockwise to loosen it. Remove the nut and the spring beneath it, then slide out the skewer.

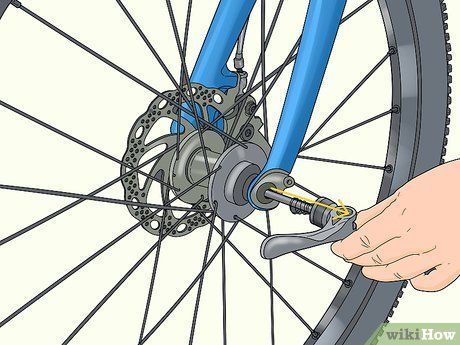

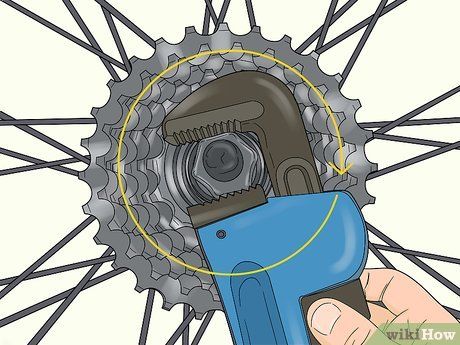

Unscrew the freewheel for rear tires: Slide a freewheel remover over the nut at the center of the freewheel. Turn it counterclockwise with a wrench to loosen the nut, then lift off the freewheel.

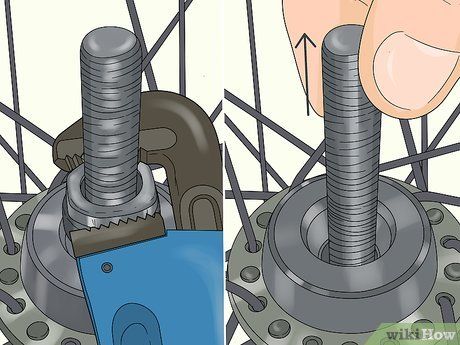

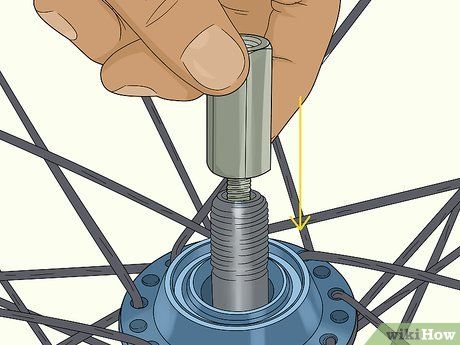

Extract the axle by loosening the locknut and cone: Use a wrench to secure the cone at the axle's base, and another wrench for the nut at the axle's end. Turn the nut counterclockwise to loosen and remove it. Pull out the spacer tube between the nut and cone. Unscrew the cone nut counterclockwise, then slide out the axle.

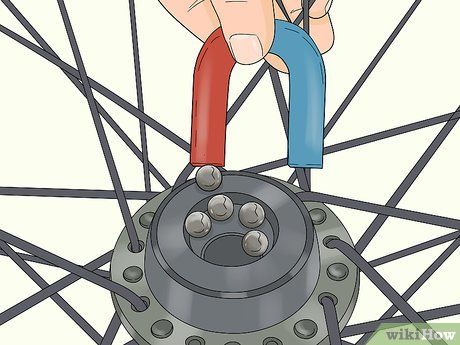

Remove old ball bearings with a magnet: Lift off the cone to expose the bearings on each side. Use a magnet to retrieve all the bearings from the hub. Repeat the process on the other side.

Clean the wheel hub with paint thinner: Apply paint thinner on a clean rag and wipe the inner and outer parts of the hub, where the axle passes through. Ensure the threads at the hub's end are also cleaned. You can use mineral spirits or rubbing alcohol as alternatives. Soak greasy parts in paint thinner for 5 minutes, then wipe off excess grease. Wash hands with soap and water afterward.

Installing New Ball Bearings

Grease both sides of the hub: Use a grease injector to apply grease around the rim of the hub. Ensure it doesn't overflow. Repeat the process on the other side of the wheel. Opt for lithium-based grease to prevent water intrusion, available at bike shops or online.

Embed the new bearings in the grease: Use tweezers to place the new bearings in a circle around the hub opening. Press them down to adhere to the grease. Replace each bearing removed on both sides. You can purchase new bearings from bike shops or online. Most bikes use 1/4' bearings for the rear wheel and 3/16' for the front. Double-check your bike's specifications in the user manual to ensure the correct size.

Reassemble the axle to encase the new bearings: Insert the axle through the hub until the cone covers one side's bearings. Secure the axle by screwing the cone onto the other side. Slide the spacer back on and tighten the nut at the end. Use a wrench to ensure everything is snug. Make sure the axle allows smooth wheel rotation. Loosen the nut slightly if the motion feels tight or jerky.

If you worked on a rear tire, replace the freewheel: Slide the freewheel back onto the axle. Replace the nut and place the freewheel remover over it. Tighten it clockwise with a wrench.

Thread the skewer through the axle again. Unscrew the nut from one side, slide the skewer through the axle from either end, and secure it by screwing the nut back on the opposite side.

Reattach the wheel to the bicycle. Hoist the wheel up, aligning it with the bike's frame slot. Secure it in place by either pushing down the quick-release lever or tightening the axle nut. If it's the rear wheel, remember to thread the chain over the freewheel.

Cartridge Bearings Removal

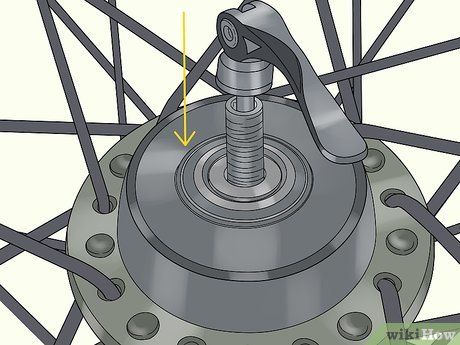

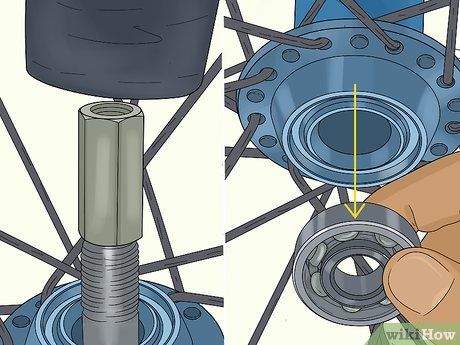

Unfasten the axle end caps. For bikes equipped with cartridge bearings, simply pull off the end caps with your hands or pliers. If they resist, consider gently leveraging them out with a vise, taking care not to crack these plastic components. Safeguard all removed parts to avoid misplacement.

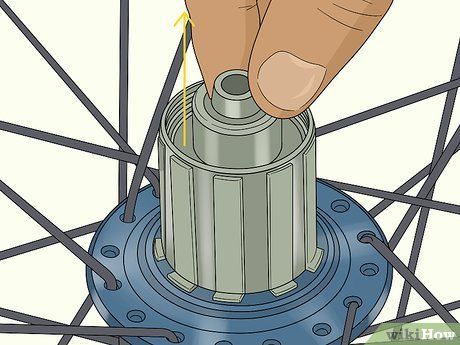

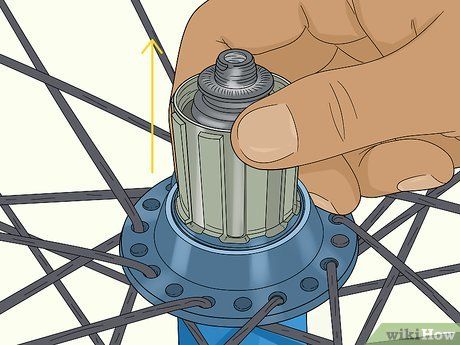

Extract the freehub to access bearings. Locate the freehub under the end caps on the bike's drive side, typically the right side. Pull off the freehub as you did the axle caps, noting a spring and two caps underneath. Keep these components together in a secure location. If your bike model requires it, unscrew rather than pull off the freehub.

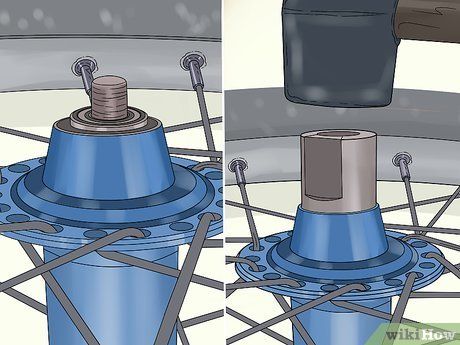

Position an axle protector on the non-drive side's axle. With the left side of the tire facing upwards, insert an axle protector into the hub, ensuring a snug fit around the axle. Axle protectors are available at bike shops or online.

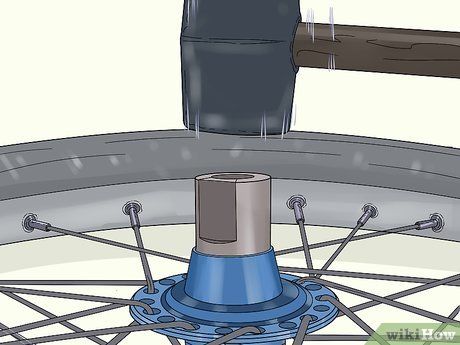

Use a hammer to dislodge the bearing via the axle protector. Employ a rubber mallet or a hammer equipped with a rubber cap to lightly strike the top of the axle protector. Continue until the bearing ejects from the opposite side. Avoid hammering the hub directly to prevent damage.

Turn the wheel to extract the second bearing. Rotate the wheel to bring the drive side to an upper position, place the axle protector, and gently tap out the second bearing.

De-grease the hub and detached parts with paint thinner. Use paint thinner on a clean cloth to clean the hub's grease. Submerge the axle, caps, and removed components in solvent for 5 minutes, then dry them. Alternatives include mineral spirits or rubbing alcohol. Post-cleaning, wash your hands thoroughly. If you have sensitive skin, wearing gloves is advisable.

New Cartridge Bearings Installation

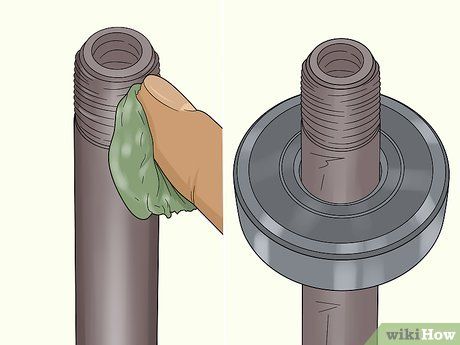

Lubricate the hub for smooth bearing insertion. Spread a thin coating of bicycle grease on both the hub's interior and exterior to fend off rust and enhance movement. A grease gun or hands work well for application. Opt for lithium-based grease to guard against water damage.

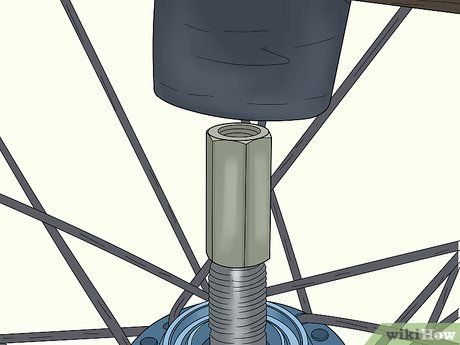

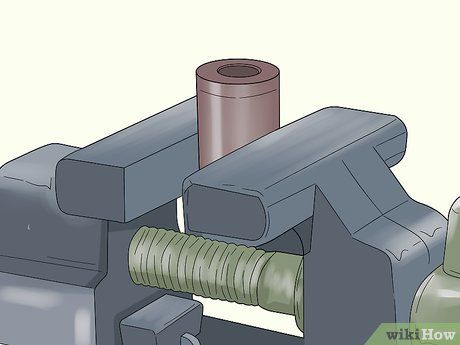

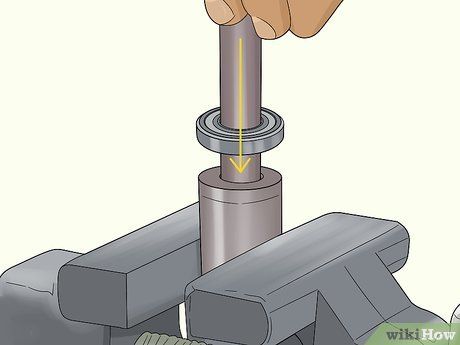

Secure an axle drift in a vise. Position the drift vertically and tighten the vise to hold it steady. An axle drift, purchasable at bike shops, aids in aligning the bearing into its slot.

Mount a new bearing on the axle's sides. After greasing the axle and bearing, fit the bearing onto one side of the axle, allowing the axle to slightly protrude. It’s not time to tighten it just yet. For rear wheels, start with the axle’s longer, drive side.

Align the axle with the drift. Orient the axle so the bearing-end faces downwards and place it into the drift, ensuring it stands upright.

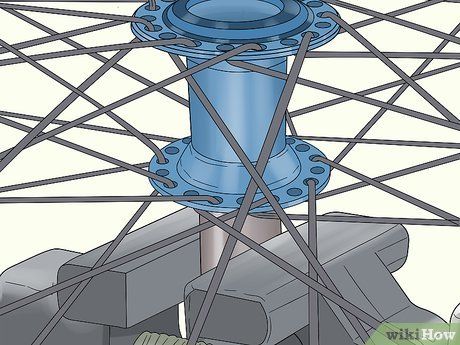

Position the wheel over the axle. Align the wheel's hub with the axle and pass the axle through the hub until the bearing fits snugly inside. Rest the wheel atop the vise, matching the drive sides correctly for rear wheels, as the wheel’s hub is broader on the drive side.

Insert the other drift from the opposite side of the hub. Align the drift with the axle and hub, ensuring the wheel side faces upward. Gently maneuver it over the axle and into the hub.

- There's no need to force the drift tightly into the hub; it simply needs to rest atop the hub opening.

Use a hammer to gently tap the drift and secure the hub in place. Employ a hammer to lightly tap the drift. Continue tapping until the bearing is fully seated within the hub.

- You can confirm the bearing's insertion by inspecting beneath the wheel, near the vise. Once the bearing is out of sight, it's within the hub.

- Opt for a rubber mallet or a hammer with a rubber base to prevent any damage to the wheel.

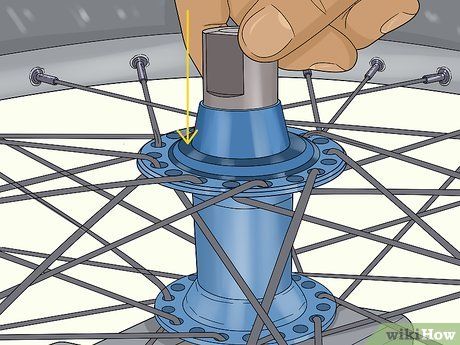

Position the other bearing onto the upper side of the axle. Allow the bearing to rest on the hub opening. Next, position the drift over the bearing and gently tap it until the bearing enters the hub.

- You may need to elevate the axle from below to provide sufficient clearance for the bearing to slide over.

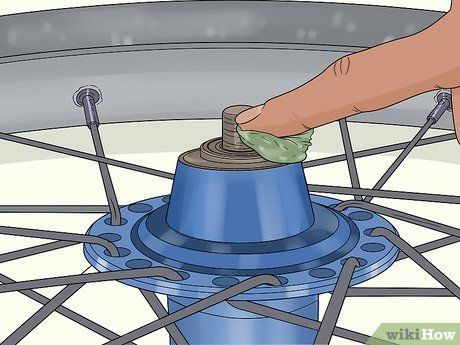

Apply grease to the new bearings to shield the hub from harm. Take a bit of grease on your fingers and spread it across both sides of the hub to coat the new bearings. This helps prevent corrosion and water damage.

- Apply only a thin layer of grease; excessive application could potentially seize the axle.

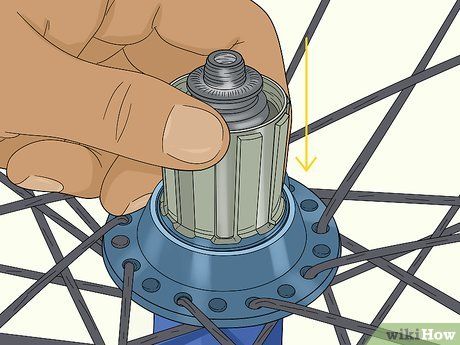

Reconstruct the bike freewheel body. Lightly grease the two caps that were previously beneath the freewheel. Slide them onto the axle, followed by the spring. Finally, reattach the freewheel body onto the axle.

- If you're concerned about forgetting the correct assembly sequence, consider taking photos as you progress to serve as a visual guide.

Install the axle end caps. Attach the end caps to each side of the axle, ensuring they click into place.

- When buying a bike, first determine its intended use—be it for leisure, fitness, or commuting.

- Consider your budget and select a bike that fits your requirements.

Required Items

Uncovering Ball Bearings

- Wrench Set

- Freewheel Removal Tool

- Cleaning Rags

- Paint Thinner

Inserting New Ball Bearings

- New ball bearings

- Grease

- Wrenches

- Freewheel remover

Removing Cartridge Bearings

- Pliers

- Wrench

- Paint thinner

- Axle protector

- Hammer

- Rags

Inserting New Cartridge Bearings

- New cartridge bearings

- Grease

- Vise

- Hammer

- Axle drift

Pointers

-

Allocate a specific space to keep all removed parts organized to prevent misplacement. Arrange the pieces in the order they were taken off to aid in reassembly.

Advisories

- Incorrectly replacing bearings can lead to bike malfunction, posing a risk to your safety. If you're uncertain about your bike repair skills, it's advisable to seek professional assistance from a bike shop.