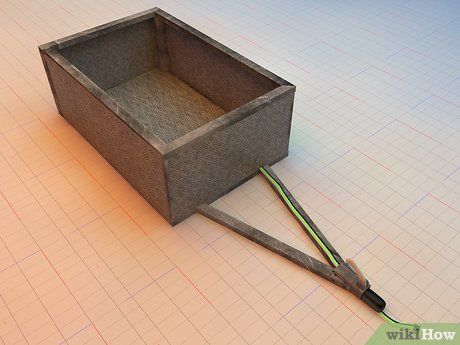

A trailer, a versatile cart that attaches to a vehicle's rear, is ideal for transporting bulky items such as furniture, lumber, and landscaping gear. While various trailer types exist, a common size for everyday use is 6 feet (1.8 m) by 4 feet (1.2 m). This size accommodates most household items but is too small for vehicle hauling. To construct this trailer, fashion the bed using rectangular metal tubing from a hardware store. Weld these sections together, then fashion the cage and tailgate with metal pipe. Lastly, attach the axle and wheels to complete the trailer.

Procedures

Building the Framework

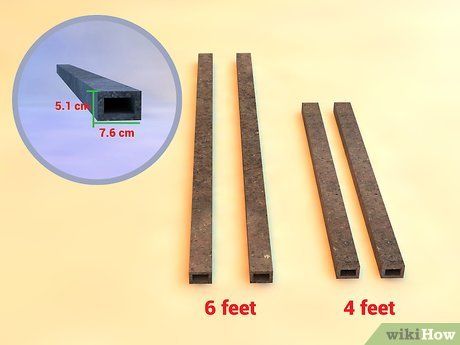

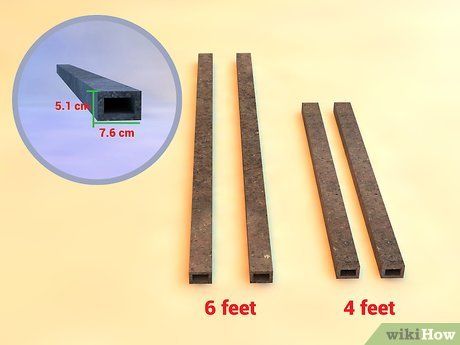

Procure four 2 in (5.1 cm) x 3 in (7.6 cm) pieces of rectangular steel tubing for the perimeter. These perimeter pieces form the rectangle for the trailer's base. For this trailer, acquire 2 length pieces measuring 6 feet (1.8 m) and 2 width pieces measuring 4 feet (1.2 m). Purchase either pre-cut pieces or a longer piece to cut to size yourself.

- For this trailer, you'll need a total of 20 feet (6.1 m), or 240 inches (610 cm), of steel for the base. Ensure you have enough material to complete the project.

- If constructing a trailer of different dimensions, adjust this step accordingly.

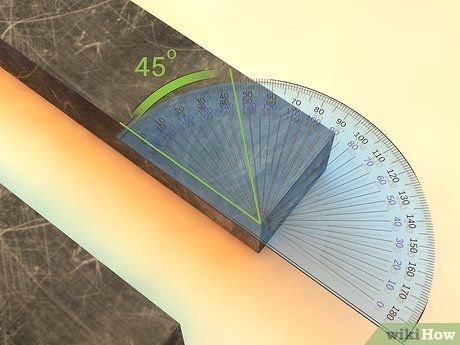

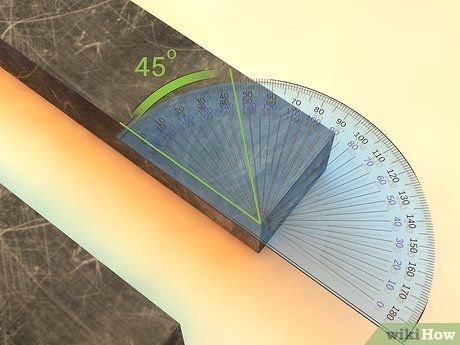

Create a 45-degree cut at the end of each perimeter piece. Utilize a protractor to measure and mark a 45-degree angle on both ends of every perimeter piece. Ensure that the angles on each base piece face the same direction. Then, use a power saw or miter saw to cut the angle on each piece.

- Miter saws are recommended for accuracy as they allow you to adjust the saw to the desired angle.

- Ensure you use a blade suitable for cutting metal if using a power saw.

- Always wear protective goggles and gloves while cutting metal. Consider using a welding mask for additional safety as metal cutting produces sparks.

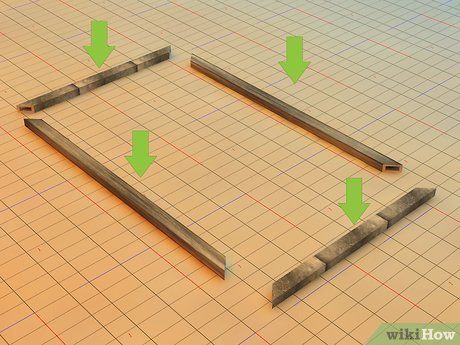

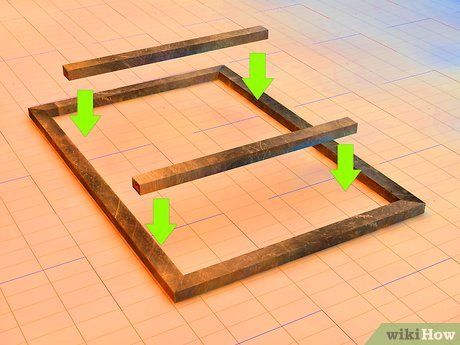

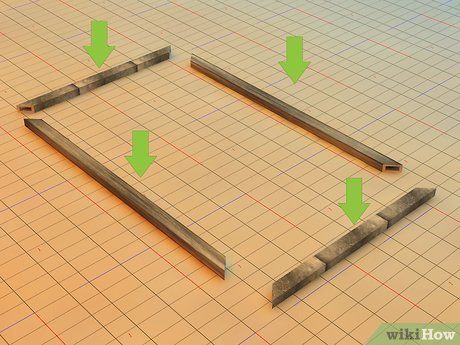

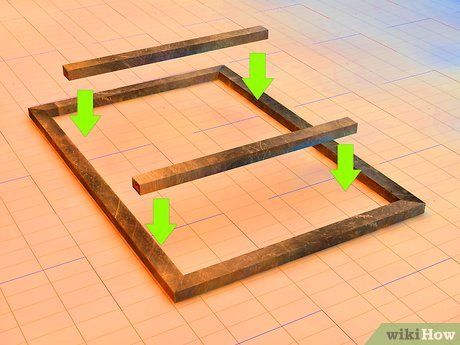

Position the base pieces on a level surface. After cutting the angles, arrange the trailer perimeter on a flat surface such as your driveway or garage floor. Lay down one of the 6 ft (1.8 m) pieces, then fit a 4 ft (1.2 m) piece into each corner. Complete the rectangle by placing the last 6 ft (1.8 m) piece.

- Ensure the pieces are tightly pushed together to minimize gaps.

- If unsure about the flatness of the surface, use a level to check.

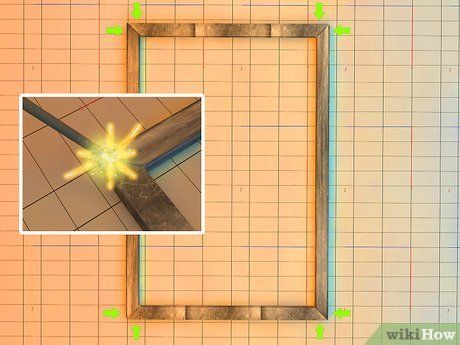

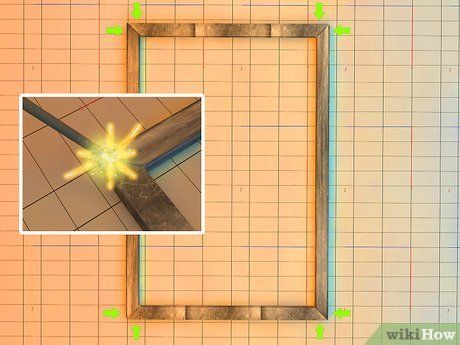

Perform welding to join the perimeter pieces. Once the perimeter is laid out, weld the pieces together using a blowtorch or similar welding tool. Start by welding along the corners of the rectangle, focusing on areas accessible first. Allow the metal to cool before flipping it over to weld the bottom.

- Check for any gaps or holes in the welds to prevent water ingress and rusting.

- You can rent welding equipment from hardware stores or purchase your own.

- Wear appropriate safety gear such as a welding mask, thick gloves, and a leather apron. Avoid touching freshly welded metal until it has cooled down completely.

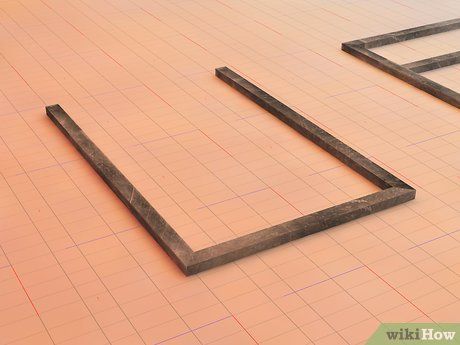

Trim a support beam for the trailer bed's center. Utilize the same steel beams used for the perimeter to cut a piece matching the width between the two longer sections of the perimeter. Fit the cut piece between the length pieces to ensure a snug fit.

- A tight fit ensures better welding performance; do not worry if some pressure is required to insert the piece.

Weld the support beam at the midway point of the trailer's length. Measure the trailer's length and mark the midpoint using chalk. Fit the support beam at this point and weld it securely in place.

Installing the Trailer Hitch

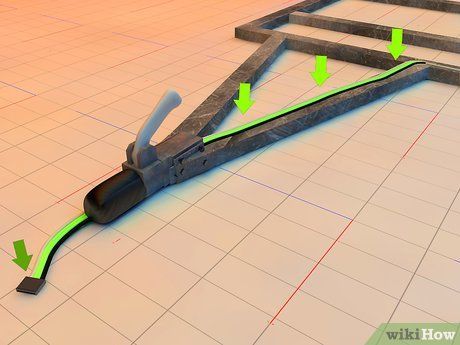

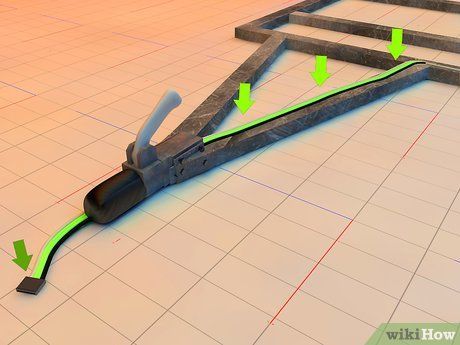

Prepare a 4.5 ft (1.4 m) piece of metal for the hitch. The hitch, which connects to your vehicle, requires a 4.5 ft (1.4 m) metal piece. Use the same steel material as the perimeter and cut it accordingly.

- A 4.5-foot (1.4 m) length is standard for typical trailer and towing setups. The tongue should generally be half the length of the towing vehicle plus 1 foot (0.30 m) to ensure sufficient turning clearance.

- If the tongue exceeds 5 ft (1.5 m) in length, it requires additional reinforcement for stability.

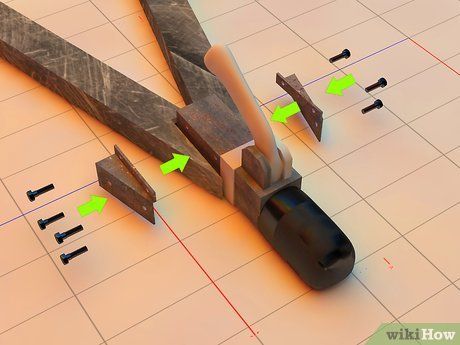

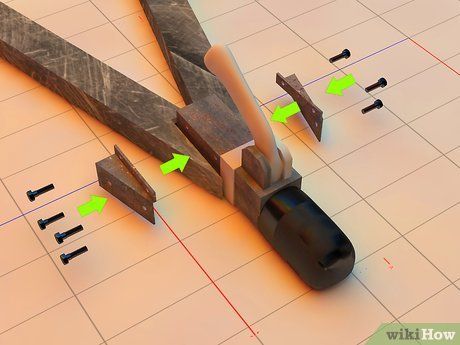

Create notches in the hitch and rear support beam for interlocking. These notches facilitate the secure fitting of the hitch and support beam. Measure the distance from the center support beam to the outer rear beam of the trailer. Transfer this measurement to the hitch and mark it. Cut out a section of the hitch halfway up, matching the width of the support beam. Similarly, find the midpoint of the support beam and cut a notch of the same width halfway down the beam.

- For convenience, a portable power saw is preferable over a miter saw for this task.

Align and interlock the notches. Insert the notched hitch into the corresponding notch on the support beam. Ensure the hitch rests evenly on the ground and reaches the center support beam.

- Verify the center alignment by measuring from the two rear corners of the trailer bed to the hitch tip. Both measurements should be equal, indicating proper centering of the hitch.

Securely weld the hitch to the trailer bed. Two key connection points exist between the hitch and trailer bed: the end of the hitch reaching the center support beam and the notch on the rear beam. Weld both points to firmly attach the hitch.

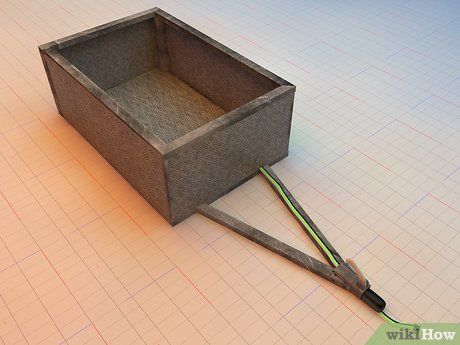

Connect the hitch to the tongue's end. Finalize the tongue by adding a hitch connection, essential for linking the trailer to your car. Obtain a hitch connector compatible with your car's hitch size. Attach it to the tongue's end and weld it securely.

- Hitch connectors are readily available at automotive stores; ensure you choose one matching the tongue's width.

- For connectors with bolt holes, attach the connector to the tongue, drill corresponding holes, insert bolts, and weld the connector securely in place.

Building the Enclosure and Tailgate

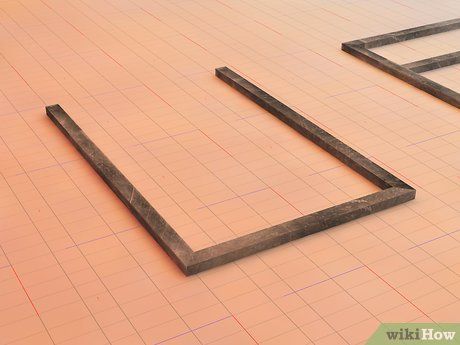

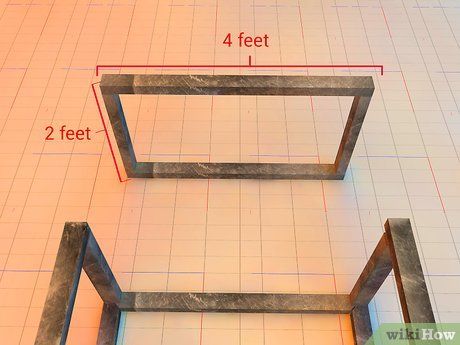

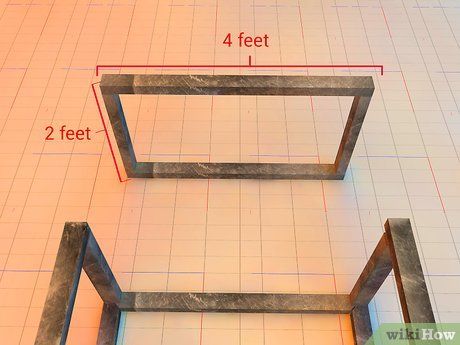

Construct a cage top matching the trailer's perimeter using metal pipes. The cage top, with three sides, mirrors the trailer bed's dimensions. Use 1-inch (2.5 cm) diameter metal pipes: 2 pieces measuring 6 ft (1.8 m) and 1 piece measuring 4 ft (1.2 m). Position the longer pipes parallel on a flat surface, placing the shorter pipe between them at one side to form a 3-sided rectangle. Weld the corners together.

- Standard metal tubing is suitable for constructing the cage top.

- If the pipes are not the correct size, measure and cut them accordingly.

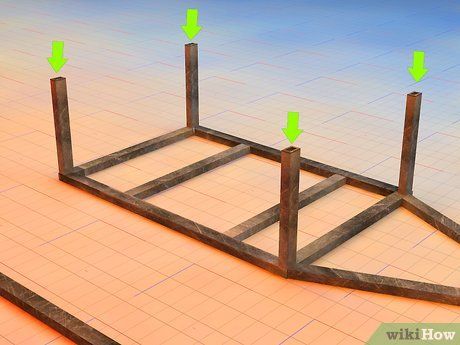

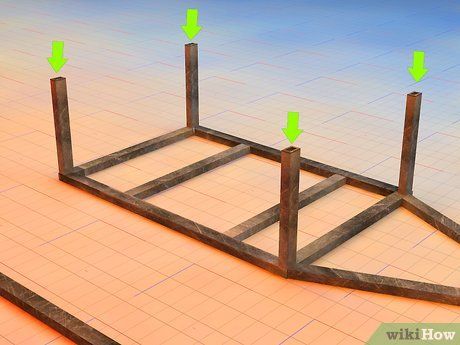

Weld vertical metal pipes to each corner of the trailer bed. These serve as support beams for the cage top. Cut 4 pieces of metal tubing measuring 2 feet (0.61 m) each, and weld one to each corner of the bed.

- The height depends on the intended cargo; 2 feet (0.61 m) is adequate for most needs, though taller cages may be necessary for larger loads.

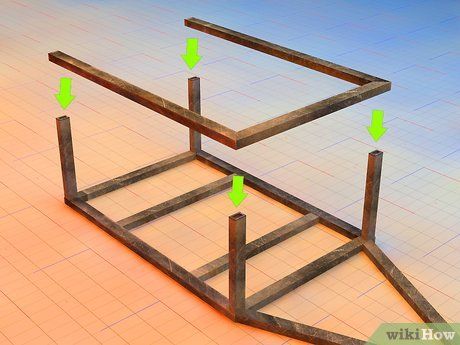

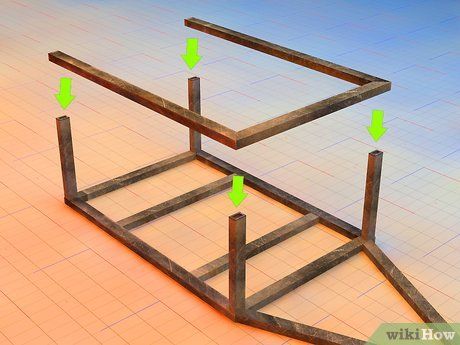

Attach the cage top to the vertical metal pipes. Once the cage top is assembled, elevate it into position, ensuring the open side faces away from the trailer tongue. Rest it on top of the support beams and weld it securely in place.

- Enlist assistance to lift and hold the cage top in position while welding for easier execution.

Fabricate a trailer tailgate using metal tubing. Utilize the same tubing employed for the cage construction. Cut two pieces to 4 ft (1.2 m) length and two to 2 ft (0.61 m) length. Arrange the longer pipes parallel and place the shorter pipes at each end to form a rectangle. Weld the corners together and affix metal mesh over the open section.

- For a simpler approach, opt for a single piece of metal for the tailgate, although it will be heavier.

- Metal mesh can be sourced from hardware stores or scrapyards.

Secure the tailgate to the trailer using door hinges. Employ two standard door hinges. Measure 6 inches (15 cm) inward from each side at the trailer's bottom and mark these points. Weld a hinge at each mark, then weld the bottom of the tailgate to each hinge.

- Various methods can be employed to close the tailgate. For a straightforward solution, use a chain wrapped around the gate and bar to secure it.

- Alternatively, affix connectors to the gate and trailer bed. Acquire four circular metal loops from the hardware store. Weld two onto the top corner of the cage facing backward, and weld the other two onto the outer top edge of the tailgate, facing outward. Align the loops when closing the gate and insert pins to secure it closed.

Sheath the bed and sides with metal mesh. Finalize the trailer bed by covering it with metal mesh. Cut a mesh sheet to match the base size and attach it by welding down each point where it contacts the trailer bed. Cut additional sheets to fit each side of the bed and attach them using the same welding method.

- Some may opt for plywood for the trailer base due to its cost-effectiveness and lighter weight. If heavy loads won't be transported, plywood can be laid down for the trailer base.

Mounting the Axle and Wheels

Purchase an axle kit from a hardware store. Select high-quality axles for your trailer wheels. Hardware stores offer kits comprising axles and tire attachments tailored to trailer dimensions.

- Some may consider using old car axles for a more economical choice. If this option is preferred, check scrap yards for additional parts.

- Keep in mind that car axles and tires will be heavier than trailer components.

Position the axle 28.8 inches (73 cm) from the rear of the bed. When constructing single-axle trailers, guidelines suggest placing 60% of the trailer length in front of the axle and 40% behind it, ensuring optimal balance. For a 6 ft (1.8 m) trailer, position the axle 28.8 inches (73 cm) from the back of the bed.

- For trailers of different lengths, calculate 0.4 times the total length to determine the distance for axle placement from the trailer's rear.

Secure the axle clasps to the underside of the trailer bed. Each side of the axle features 2 clasps designed to hold it in position. Press these clasps against the trailer beam and weld them securely.

- If the clasps struggle to remain in place, use clamps to hold them steady while welding.

Install and inflate the tires. Finalize the trailer assembly by mounting the tires. Slip the rubber onto the wheels and use an air compressor to inflate the tires to the recommended pressure.

- The typical recommendation for trailer tires is 35-40 psi, although it's advisable to check the specifications provided with your product.

- If you're unsure about the correct tire installation and inflation procedure, seek assistance from a professional to ensure the safety of your trailer.

Pointers

Cautions

Always ensure you have the correct safety gear before welding.

When towing your trailer, start with slow and cautious driving to verify its stability.

Materials Needed

- 2 in (5.1 cm) x 3 in (7.6 cm) rectangular steel tubing

- 1 inch (2.5 cm) steel pipe

- Metal mesh

- Axle kit

- Blowtorch or similar welding tool

- Metal saw

- Welding mask

- Welding gloves

- Leather apron

- Trailer hitch

- Door hinges