For those hesitant to invest in a pricey $3,000 workbench, this article offers a solution. It outlines the construction of a durable, functional, and visually appealing workbench using affordable materials, making it accessible to a wide audience.

Key Steps

Determine the Ideal Dimensions: A successful workbench must be tailored to your specific needs, with considerations for height, width, and length. Features like quality vises and storage options should align with your woodworking style and preferences.

Ensure Strength and Durability: Torsion box designs rely on internal grids for stability and resilience. Construct your workbench to withstand typical woodworking tasks, ensuring it remains rigid and true over time.

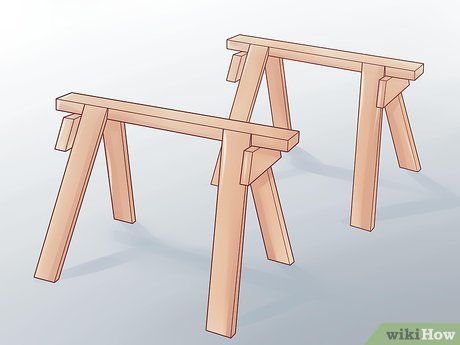

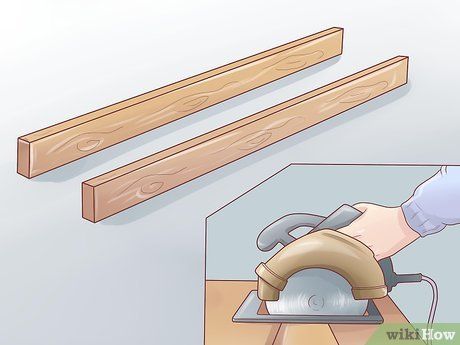

Create a Level Foundation: The initial step involves establishing a level surface to commence construction. This can be achieved by using boxes, sawhorses, or a spacious area, onto which rails or lengthy 2x4s are placed and leveled.

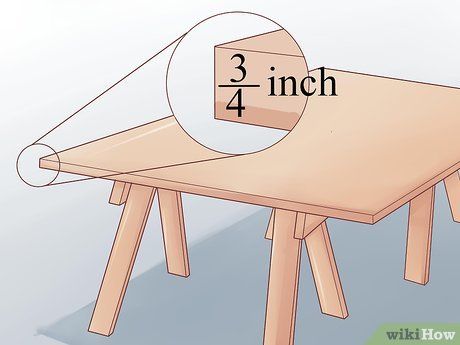

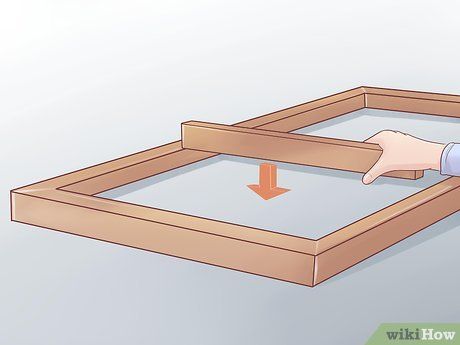

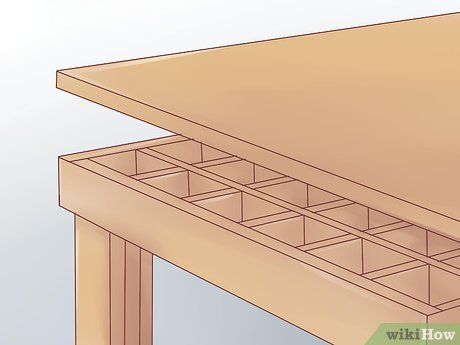

Position the Base Plywood or MDF Sheet: Place the first sheet of mid-grade plywood or MDF atop the 2x4s, ensuring it remains level. This sheet forms the bottom layer of the workbench top and serves as the foundation for the torsion box.

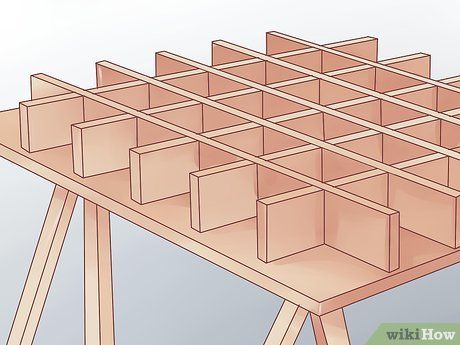

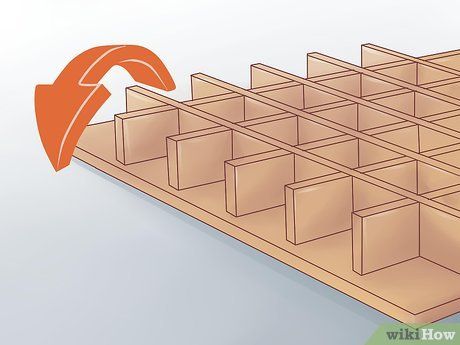

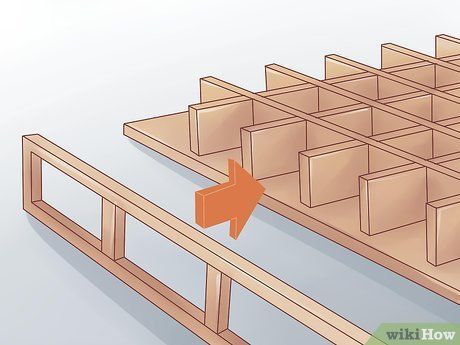

Construct the Internal Grid: Once the outer lines are marked, proceed to create the internal grid or squares within these outlines. Utilize 1x2 lumber to form equally-sized squares across the length and width of the top.

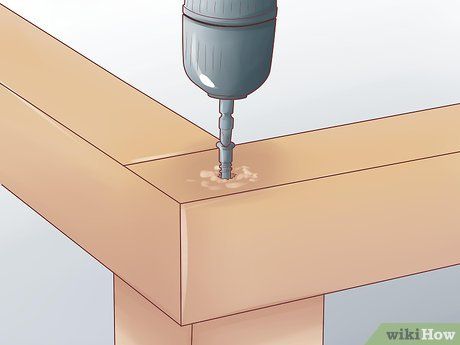

Assemble the Outer Frame: Using 1x2 lumber, build the outer frame of the workbench. Pre-drill holes or employ a brad nailer and adhesive to secure the frame along the previously marked lines on the plywood or MDF base.

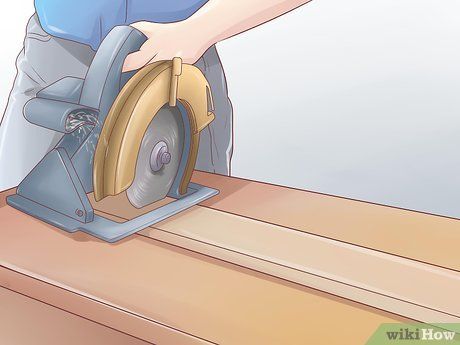

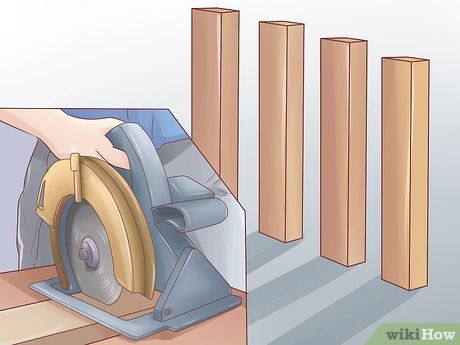

Prepare the Grid Components: Cut the 1x2 lumber to the appropriate lengths for constructing the grid. Ensure that the long pieces align with the bench's length, while the shorter ones span across its width.

Position Short Strips: Place the short strips along the grid's designated positions against the outer frame, ensuring squareness with a carpenter's square. Clean off any excess glue for a tidy finish.

Add Long Strips: With the short strips in position, add the long strips using glue, screws, or brad nails. Ensure the long strip aligns with the short strips and touches the outer frame at each end.

Continue with Short Strips: Proceed to add more short strips as done in the first row, securing them with glue, screws, or brad nails. Ensure they are square to the long strips and toenail them if necessary.

Install Additional Long Strips: Add another long strip following the same method as before, then add the short strips using glue, screws, or brad nails. Apply glue at the intersections for added strength.

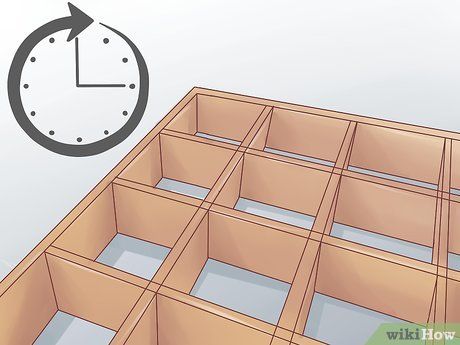

Allow Glue to Dry: Let the glue dry overnight before proceeding. Once dried, attach the grid to the bottom plywood, which serves as the base of your workbench.

Once the glue has dried overnight, with assistance, flip the bottom and grid over, placing it back on the 2x4s to ensure a flat, level surface. Double-check for levelness and squareness. Mark lines on the bottom to align with the center lines of the 1x2s underneath, then secure with brad nails for added strength.

After completing the brad nailing on the bottom, flip it over again, verifying flatness and squareness. Add the top layer of plywood or MDF onto the grid. If you plan to replace the top piece in the future, avoid gluing it in place. Instead, use screws to attach it to the grid below, ensuring a secure fit. Trim the outside edges of the top and bottom pieces flush with the outer frame.

Once assembled, trim the outer edges of the top and bottom plywood or MDF to match the outer frame.

The outer trim should be hardwood, 1' to 1-1/2' thick, and match the thickness of the torsion box. Miter the corners or use a box joint for added aesthetics. Attach the outside trim with glue and screws, rounding over the edges to prevent splintering.

After rounding over edges and sanding the entire top, apply a quality oil finish to protect the torsion box and enhance its appearance. Consider using a mixture of boiled linseed oil and tung oil for optimal results, applying about three coats.

Construct a sturdy frame using three layers of 2x6 material for the legs. The new torsion box top requires a robust frame to support its weight while ensuring strength, stiffness, and durability.

Your top frame can be cost-effective yet visually appealing. Select high-quality 2x6s and 2x8s from your local lumberyard, considering yellow pine as a budget-friendly option that still offers excellent quality.

Square off the outside edges of the 2x6s and 2x8s by removing the rounded edge, approximately 1/4'-5/16'.

Determine the desired height for your workbench top and cut the 2x6s accordingly. Ensure that the height allows for comfortable working without excessive bending or reaching.

Trim one of the three 2x6 laminations to match the width of the bottom trimmed 2x6 foot and the top trimmed 2x8 rail.

After cutting the 2x6s to the desired length and width, assemble them using glue and screws, ensuring proper spacing for the foot and top rail. Utilize scrap pieces to ensure accurate placement of the short leg lamination.

Prepare two trimmed 2x6s, each cut to the width of the base frame plus an additional 3' on each side of the legs. These pieces will serve as the foot and should have a slight section removed from the center bottom for leveling purposes.

Secure the foot (trimmed 2x6) to the legs using glue and lag screws at the predetermined location. Verify the squareness of the legs and foot with a framing square for a neat appearance. Ensure the lag screws penetrate the foot/rails and extend approximately 2-1/2' into the legs without protruding through.

Install the top rail, cut to match the width of the base frame, using glue and lag screws. Similar to the foot piece, ensure a snug fit and an inset appearance when attaching the top rail.

Complete the leg assembly by attaching the long trimmed 2x8 side rails using glue and lag screws. These rails should match the bench's length minus any overhang for mounting vises. Overlap the long side rails with the end rails at the leg corners for added stability.

If desired, you can include a stretcher between the foot pieces. Attaching two trimmed 2x4s to the top edge of the foot will provide a sturdy base for adding shelves or storage cabinets beneath your new workbench.

Consider applying a nice oil finish to the base frame after rounding off any edges prone to splintering and smoothing out the surface with sanding.

To attach the top torsion box to the base frame, you can use figure eights or opt for cross pieces measuring about 2x3' positioned at the top rails of the base frame. Place four pieces—one at each end of the base frame and two evenly spaced between them—pre-drilled for screws to secure the top torsion box in place.

Tips

- Ensure that all materials for the inside of the torsion box are of the same width and thickness before beginning, as this will streamline the process and ensure proper fitment.

- Take your time and prioritize quality workmanship; your workbench will be the focal point of your shop, so take pride in its construction.

- Before starting, have a well-detailed drawing and clear instructions. Familiarize yourself with all the components of the bench top and base, and decide on the desired appearance and functionality beforehand.

Warnings

- These torsion boxes are heavy, so enlist help when moving or lifting them. Ensure your design prevents overturning by selecting appropriate dimensions for height and width.

Things You'll Need

- A table saw

- Cordless drill/screw gun

- Ratchet and socket to fit lag bolts

- Drill bits