When it's time to prepare your boat for winter storage or transportation to a new destination, utilizing marine shrink wrap is key to preserving its condition. A snug layer of shrink wrap effectively blocks out cold air, moisture, and sunlight. To apply shrink wrap, drape the material over a frame made of polyester strapping, then heat it with a shrink gun. Customize with tape, vents, and access doors as necessary to securely enclose your boat until it's ready for use again.

Procedures

Relocating and Securing the Boat

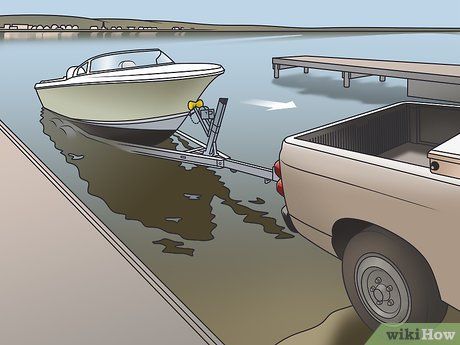

Remove the boat from the water before wrapping. Prior to winterizing your boat, relocate it to a protected area. Most marinas offer lifts to transfer larger vessels onto trailers or storage blocks. For smaller boats, utilize a winch to pull them onto a trailer positioned near the water.

- If you have a small speedboat or sailboat, it can remain on its trailer during winterization. However, for larger, heavier vessels like yachts, place them on blocks for the winter.

Select a well-ventilated spot for boat storage. Opt for a secure location such as a marina or garage. Since shrink wrap emits chemicals when heated, ensure adequate ventilation by keeping doors or windows open nearby. While working outdoors is feasible, avoid windy days as they can complicate the winterization process. If outdoor work is necessary, choose a calm, clear day.

- Wear a respirator or dust mask to protect against fumes from the shrink wrap.

- If possible, transport the boat to its winter storage spot before beginning the winterization process to avoid moving it later and risking damage to the wrap.

Seal fuel vents with shrink wrap tape. Shut off the fuel line valve to safeguard the boat. If feasible, drain any remaining fuel from the line. Then, use shrink wrap tape to completely seal the vents, preventing heat from igniting fuel vapors. Apply sufficient tape to effectively block off the vents.

- Purchase shrink wrap tape from marine supply or hardware stores, or online from shrink wrap suppliers.

- Refer to the boat manufacturer or owner’s manual to locate the vents if unsure of their positions.

Protect sharp edges with foam cushions or towels. Sharp edges pose a threat to the integrity of the shrink wrap. Cover them entirely to blunt their impact. Secure cushions or towels to these edges using shrink wrap tape or a similar adhesive. Ensure the shrink wrap can conform to these edges without tearing.

- Obtain foam insulation from a hardware store or repurpose old towels or clothing for cushioning.

- Key areas to cover include corners of windshields, antennas, and ski pylons.

Constructing a Fabric Framework

Install support posts along the centerline of the boat. Position the support posts in open areas on the boat’s deck. Each post requires a top and bottom cap for proper positioning. Place the initial post near the bow, ensuring it extends at least 10 inches (25 cm) above the boat's highest point. Position a second post near the stern.

- To craft your posts, measure the distance from the deck to the boat’s highest point. Purchase 2 in × 4 in (5.1 cm × 10.2 cm) wooden posts, ensuring they are 10 inches (25 cm) taller than your measurement. Then, equip them with foam caps available online.

- For small powerboats, two posts are sufficient. Add more posts for larger boats to adequately support the shrink wrap. Install an additional post for every 8 feet (2.4 meters) of boat length requiring coverage.

Secure support posts using polyester straps. Fasten a strap from the boat's rear to the front, threading it through the grooves on the post caps. Place additional straps horizontally across the boat, ensuring each cap is threaded. Attach all straps to grab rails or cleats along the boat’s edges to ensure stability.

- Ensure straps are tight to provide a stable frame for the shrink wrap. Loose straps result in loose shrink wrap.

- If anchoring points are unavailable, extend the strapping to the trailer beneath the boat.

Create loops at the end of each strap. Measure from the end of the strap to approximately 8 inches (20 cm) below the metal rub rail encircling the boat's edge. Cut new straps to size and tie them to cleats and edge rails, forming loops about 1/2 inch (1.3 cm) in diameter.

- Secure straps using a basic overhand knot or any secure knot of your choice.

Wrap a perimeter band around the boat. Begin at the stern and thread each strap through the previously created loops, ensuring a tight fit against the boat’s side. Secure the ends together with a buckle upon reaching the stern.

- Before tying, ensure the strap is pulled taut. Use a strap tensioning tool if needed, readily available in shrink wrap kits or online.

- Utilize the boat’s propeller as an anchor point for the perimeter band, ensuring the strap remains taut and secure.

Shrink Wrap Application

Determine the required shrink wrap dimensions. Measure from the boat's center down to the metal rub rail, adding an extra 8 inches (20 cm) for the perimeter band and an additional 6 inches (15 cm) for folding. Double the measurement to cover both sides of the boat.

- Measure the boat's highest point to ensure complete coverage, including windshields and other protrusions.

- Err on the side of excess material to avoid shortages. It's easier to trim down an oversized sheet than to deal with insufficient coverage.

Position and secure the shrink wrap around the perimeter band. Begin at the top of the support post and gradually cover the hull, ensuring the wrap reaches the perimeter band. Leave approximately 6 inches (15 cm) of excess material on all sides to cover the band, trimming any surplus with a film knife.

- Store the shrink wrap in a folded position until ready for use to prevent tearing or contamination.

- If necessary, use shrink wrap tape to join multiple pieces together, ensuring a seamless application.

Attach the shrink wrap to the perimeter band using a heat tool. Wear a heat-resistant glove for protection and hold the heat gun slightly above the wrap's edge. Gradually work around the boat, gently heating and pressing down the tucked-in edge. Leave the rear edge untouched for now.

- Exercise caution to avoid direct contact between the heated wrap and exposed skin. Apply heat carefully to prevent damage to the wrap or the boat.

Secure belly bands every 6 inches (15 cm) along the shrink wrap. Fasten polyester strapping along the trailer's length and thread it through small slits in the wrap using a film knife. Tie the strapping tightly, ensuring it is approximately 8 inches (20 cm) below the rub rail, and trim any excess material.

- Belly bands help maintain a tight seal on the shrink wrap, ensuring optimal protection.

- Once tied, further tightening of the belly bands is unnecessary.

Fasten the shrink wrap to the boat's stern. Begin tucking the wrap as done on other sides, cutting off excess material as needed. Heat the wrap's edge to secure it to the boat, paying attention to cover exposed areas like the propeller. If required, heat the wrap from underneath the stern for additional security.

- This step requires precision and may result in tearing if rushed. The wrap should hang slightly lower at the stern compared to other sections.

Heat the wrap from the stern to the bow of the boat. Hold the heat gun approximately 6 inches (15 cm) above the boat and work on one side at a time, starting near the rub rail. Move the gun steadily towards the boat's front, ensuring even heating and smoothing out wrinkles as necessary using a gloved hand.

- Heating shrink wrap resembles the motion used in spray painting. Consistent movement prevents melting and ensures a uniform application.

- Divide the boat into sections and focus on heating one section at a time to prevent overheating or melting of the wrap.

Utilize a ladder or extension tool to access the upper part of the boat. For safety, use an extension tool to reach the top portion of the shrink wrap. Attach the heat gun to the extension and work from the rear to the front until the entire surface appears smooth and free of wrinkles.

- When using a ladder, ensure stability and avoid touching the shrink wrap to prevent damage.

Finalizing and Ventilating the Seal

Seal any holes or weak spots in the shrink wrap with tape. Apply a generous layer of shrink wrap tape over holes and seams, then briefly heat the tape with a heat gun to ensure adhesion. Follow manufacturer recommendations for specific instructions on repairing damaged areas.

- Tape adheres best when applied to warm shrink wrap. Reheat the wrap briefly if necessary after cooling to ensure proper adhesion.

- Refer to the manufacturer’s instructions for guidance on using shrink wrap tape.

Install adhesive vents along the boat's sides. Position the vents above the deck, spacing them evenly along the boat's length. Use 4 to 6 vents for smaller powerboats, placing them near each corner. Directly attach the vents to the shrink wrap to allow moisture to escape and prevent mold growth.

- Positioning vents over taped fuel vents is recommended.

- Vents facilitate airflow under the shrink wrap, inhibiting mold formation.

- Consult a size guide, such as https://dr-shrink.com/boat-size-venting-chart-cheat-sheet/, to determine the appropriate number of vents for your boat.

Open the vents and install caps over them. Use a film knife to cut the shrink wrap inside the vent opening, then attach the provided cap. Once all vent caps are securely in place, the main winterization process is complete.

Fit a zippered entryway for accessing the boat if necessary. Similar to installing a vent, position the zippered door on a convenient location atop the boat's surface. Secure the door in place with tape before cutting out the opening. Use the zipper closure to seal the door shut until access inside the boat is required.

- Consider adding a zippered door provided by most shrink wrap manufacturers to maintain the integrity of the seal while allowing access to the boat during winter.

Helpful Pointers

-

When removing shrink wrap, use a plastic edge to prevent scratching your boat's surface.

-

For complete winterization, remove cushions and other fabric components from the boat. If removal isn't possible, keep cabin doors open to ensure proper ventilation.

Cautionary Notes

- Shrink wrap can become flammable if overheated. Keep a fire extinguisher nearby for emergencies.

- Be cautious when shrink wrapping to avoid damaging your boat. If unsure, consider hiring a professional for assistance.

- Heating shrink wrap produces toxic fumes. Work in a well-ventilated area and wear a respirator for protection.

Essential Supplies

- Measuring tape

- Shrink wrap

- Heat gun

- Protective padding for sharp edges

- Film knife

- Shrink wrap tape

- Minimum of 4 ventilation ports

- At least 2 2 in × 4 in (5.1 cm × 10.2 cm) posts about 10 in (25 cm) tall

- Zippered entrance