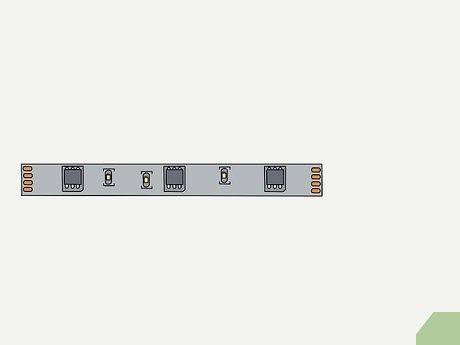

LED strip lights can be easily cut with scissors. Each LED has copper dots at the end, and cutting between these dots ensures proper functionality. After cutting, you can connect the LEDs to a power source using a quick connector or soldering. Correct connection results in a colorful display of all LEDs.

Steps

Separating LED Strips

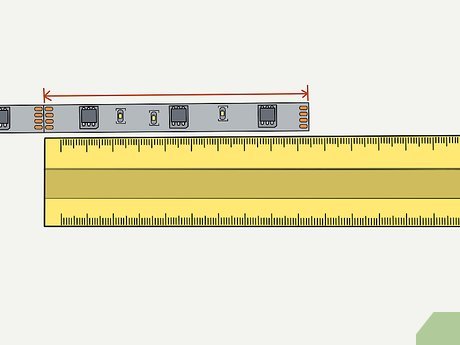

Determine the required length of LEDs. LED strips are sold in a single long strip, and you can cut individual LEDs as needed. However, cutting must be done at specific points for proper functionality. Measure the desired length before cutting any LEDs.

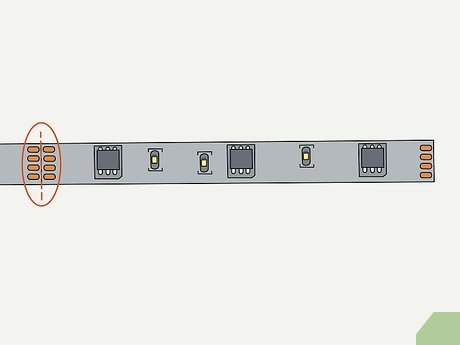

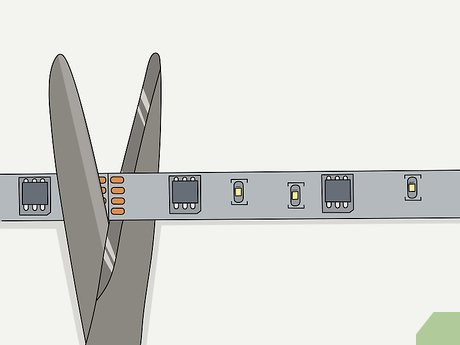

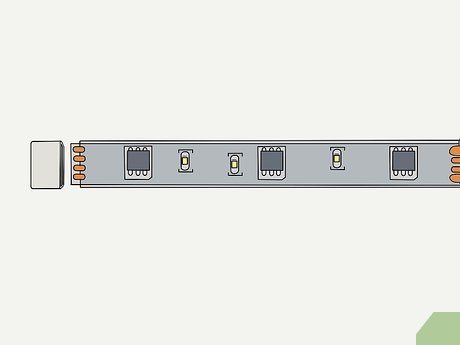

Locate the cutting line between the copper dots on the LED strip. These dots serve as connection points between each light. Look for the dashed line running through the dots and choose the closest one to your measured LED length. Remember, this line is crucial for proper functionality.

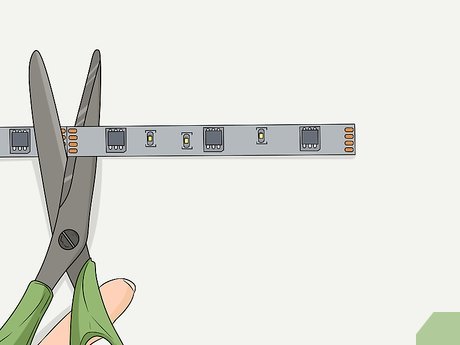

Use scissors to carefully separate the LED strip. Make sure to cut along the dotted line, which lies between the copper dots. Precision is key here to avoid any damage to the LEDs.

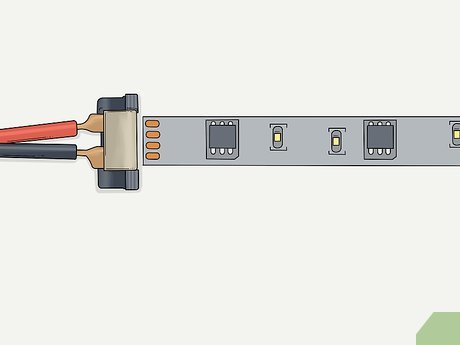

Prepare to attach LEDs to a quick connector.

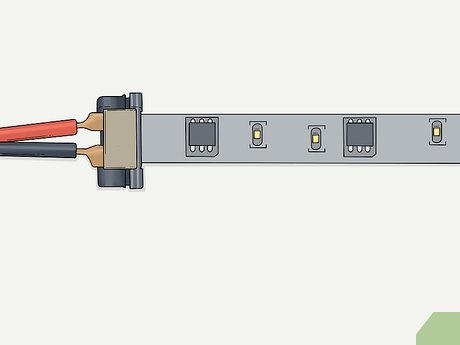

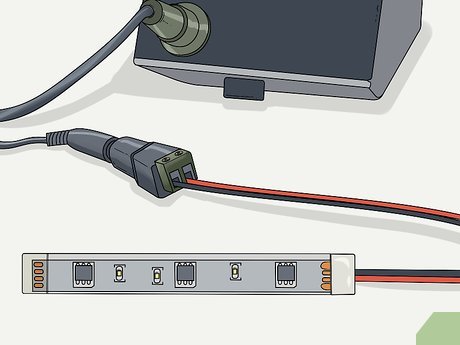

Position the quick connector correctly on the LED strip. These connectors simplify the electrical setup and usually come with + and - indicators. Align the black wire with the - and the red wire with the + accordingly.

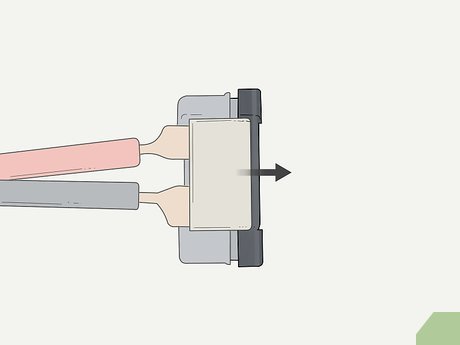

Gently remove the 1/8 inch (0.32 cm) plastic bar from the quick connector. Hold the connector securely and locate the small plastic bar, often black in color, at one end. Pull it forward to open the connector, exercising caution due to its delicate nature.

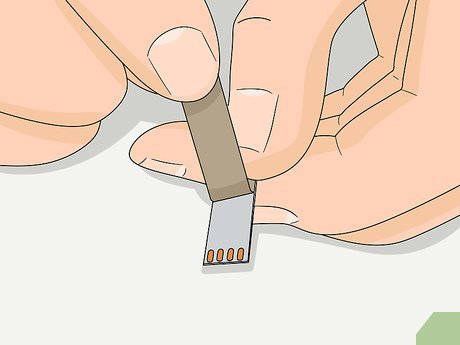

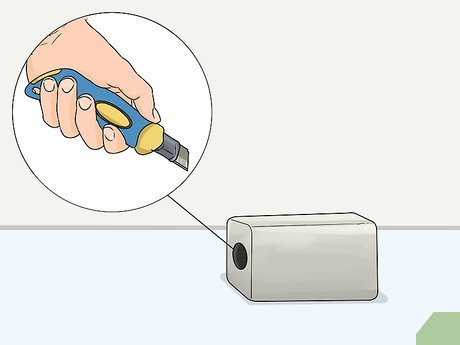

Peel off about 1/4 inch (0.64 cm) of the adhesive backing from the LED. This exposes the copper terminals. If your LEDs lack this backing, carefully remove the plastic covering the terminals using a box cutter or knife, making sure not to cut through the LED.

Insert the LED into the connector by sliding its end directly into the quick connector. Ensure proper alignment of the wires, with the black wire connecting to the + and the red wire connecting to the -.

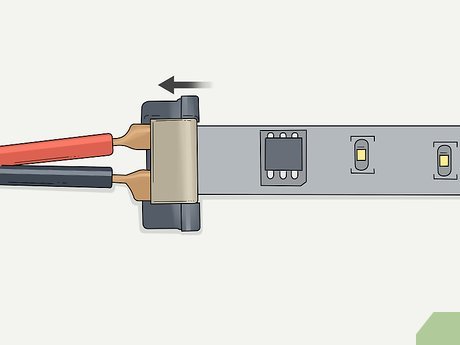

Secure the LED in place by closing the plastic bar on the quick connector. Pull the plastic bar back onto the LED to firmly hold it in position, ensuring the connection remains intact and protected from any damage.

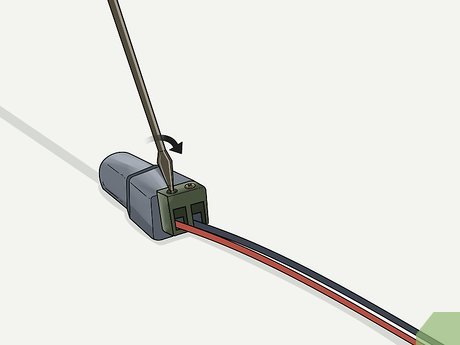

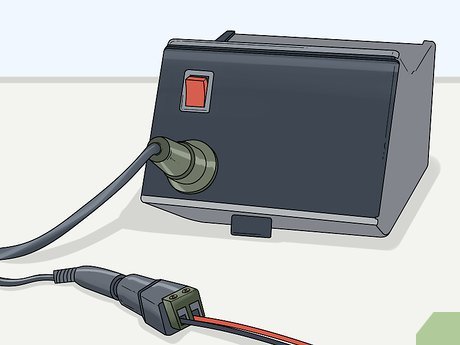

Connect the wires of the quick connector to wires of the same color on the power source. Utilize a terminal wire connector from a home improvement store. Insert the wires into the connector and tighten the screws clockwise to secure them. Connect the power supply cord to the other end of the terminal.

Soldering LEDs Together

Remove the plastic cover from the end of the LED strip. Use a sharp knife or box cutter to cut above the copper dots. Clear off any plastic debris from the dots.

Apply solder to the copper terminals of the LED strip. Heat up a soldering iron and melt solder wire onto the copper dots, ensuring complete coverage.

Create a small opening in a plastic end cap. Use a knife or box cutter to pierce the closed end of the cap, widening the hole enough to fit wires through.

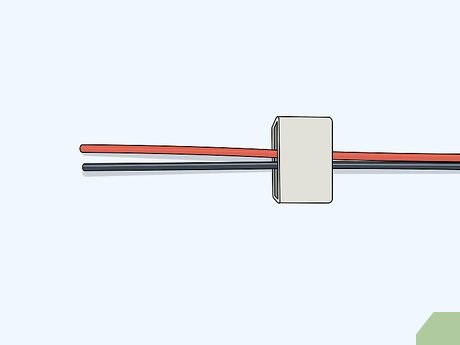

Trim and thread wires through the cap. Measure and cut black and red wires to the required length for connecting the LED to the power source. Leave a bit of extra length on each wire end. Thread the wires through the small hole in the cap.

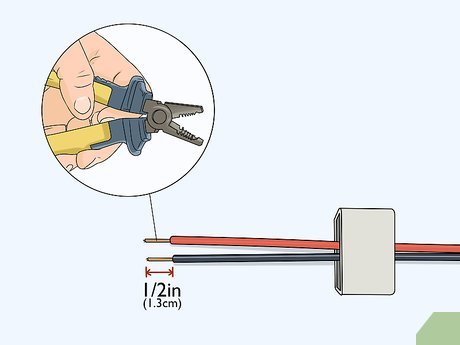

Strip the wires using wire strippers. Remove about 1/2 inch (1.3 cm) of casing from the wire ends using wire strippers, ensuring a clean cut.

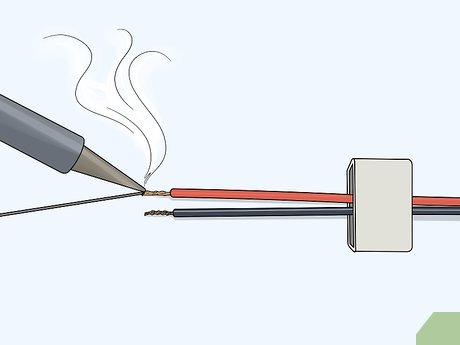

Give each wire end a twist and a coat of solder. Focus on one wire at a time. Twist the wire end to gather all the stray strands together. Reheat the soldering iron, then apply the solder to the exposed wire. Repeat this process for every wire.

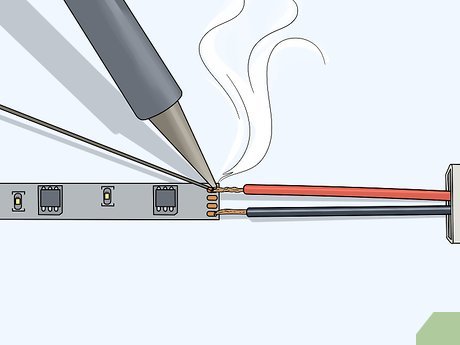

Apply solder to attach the wires to the LED. Ensure correct polarity, aligning the black wire with the LED's - terminal and the red wire with the + terminal. Touch the soldering iron to the solder on the LED to melt it, then connect the wires. Maintain pressure on the wires until the solder cools and solidifies.

Link the wires to the power supply. Insert the wire ends into the power source. You might need to twist the wire ends and cover them with shrink tubing or an end cap before testing the electrical connection. Repeat these steps to solder wires to another LED if necessary.

Secure a silicone end cap onto the LED. Obtain another plastic end cap. Fill it halfway with silicone adhesive. Press the cap onto the open end of the LED strip, ensuring the LED reaches the back of the cap.

Evaluate the LED lights. Activate the power source by flipping the switch. All LED lights should illuminate. If they don't, verify that the wires are correctly positioned. Confirm that the colored wires correspond to the correct terminals on the LED, and ensure the wires are firmly soldered to the LED.

Helpful Hints

- Only trim LEDs at designated spots as instructed by the manufacturer. Look for the dotted line or copper dots.

Important Reminders

- Exercise caution when using a soldering iron. Avoid placing it on flammable surfaces and always unplug it when finished.

Essential Supplies

Separating LED Strips

- LEDs

- Pair of scissors

Attaching LEDs to a Rapid Connector

- Rapid connector

- Utility knife or box cutter

Joining LEDs with Solder

- Utility knife or box cutter

- Soldering iron

- Metal solder wire

- Plastic end caps

- Wire strippers

- Silicone adhesive