When operating a 3D printer, the nozzle can sometimes become obstructed, impeding the printing process. If you observe issues such as filament blockages or inconsistent extrusion, it may be necessary to perform a cleaning procedure. This guide outlines two methods for cleaning your nozzle: a basic unclogging method and a more thorough deep cleaning process.

Steps

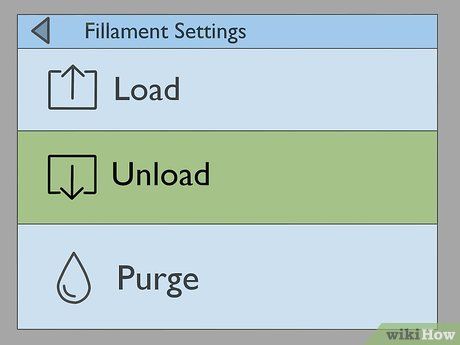

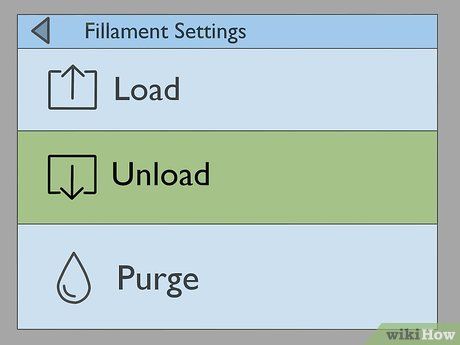

1. Remove the filament currently loaded in your printer: Access the “Unload” function either through your printer's menu or the accompanying software. Wait for the nozzle to reach operating temperature, then carefully extract the filament to avoid damaging the printer.

- If the filament is stubborn, increase the nozzle temperature until it can be easily removed.

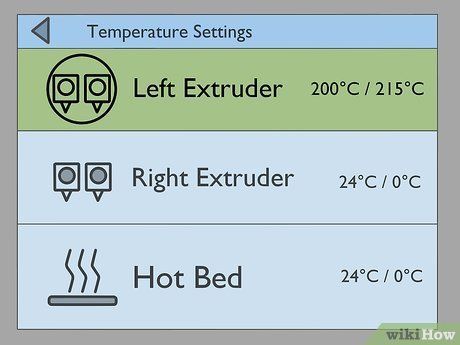

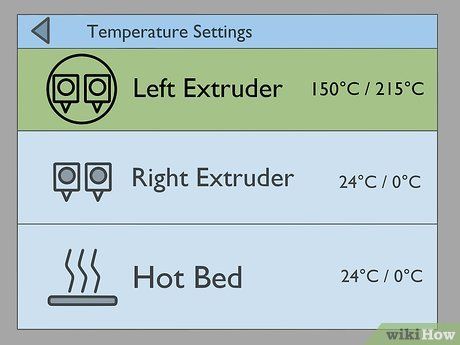

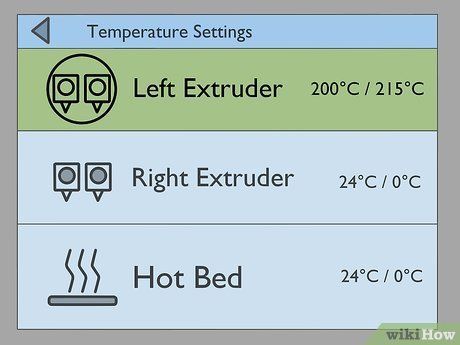

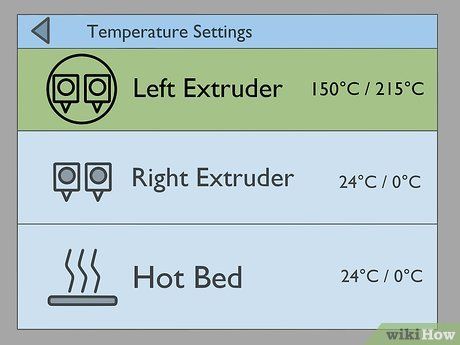

Preheat the nozzle to 200 °C (392 °F). Once the filament has been unloaded, initiate the preheating process for the nozzle to reach a temperature of approximately 200 °C (392 °F). This ensures that any residual filament within the nozzle is softened, facilitating its removal. Allow the nozzle to fully heat before proceeding further.

Pro Tip: Adjust the temperature settings specifically for the nozzle during the cleaning process, avoiding unnecessary heating of other components.

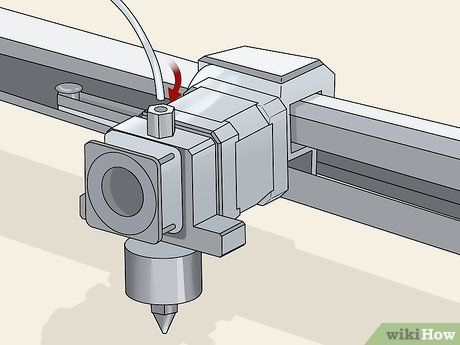

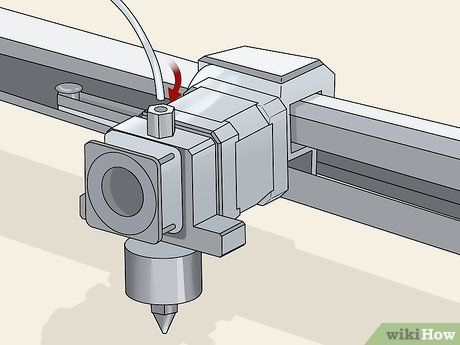

Insert a transparent ABS or nylon filament into the nozzle and hold for 10-15 seconds. Utilize ABS or nylon filaments due to their high melting points, which aid in effectively dislodging any obstructions. Insert the filament into the nozzle opening and push it as far as possible, maintaining pressure for 10-15 seconds to allow slight melting.

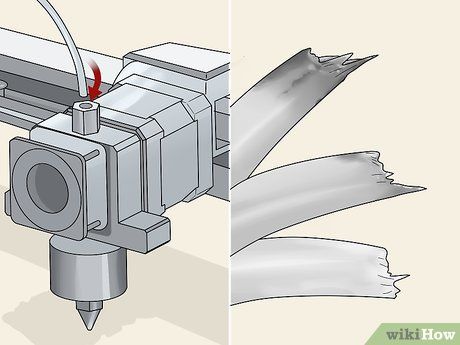

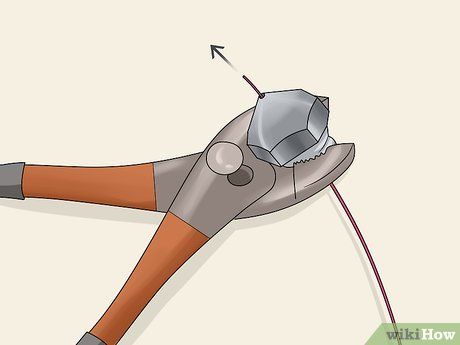

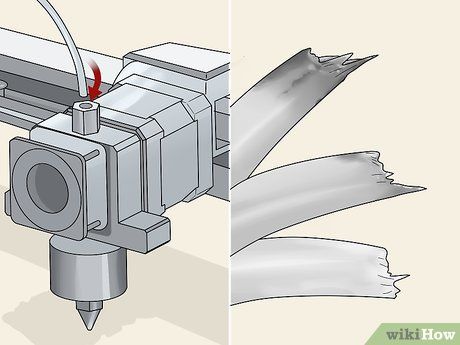

Withdraw the filament and inspect for debris before trimming the end. Following the 10-15 second interval, swiftly retract the filament from the nozzle. The transparent ABS or nylon filament will reveal any contaminants, facilitating easy identification. Trim approximately 5 cm (2.0 in) from the soiled end using scissors or snips.

Repeat the procedure until the filament emerges clean. Continuously insert and withdraw the filament from the nozzle in 15-second intervals. With each repetition, the amount of debris captured by the filament should decrease. Ensure to discard the trimmed end of the filament after each cycle to prevent recontamination of the nozzle.

Performing a Thorough Cleaning Using Acetone

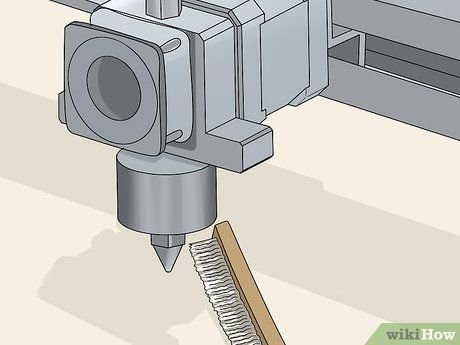

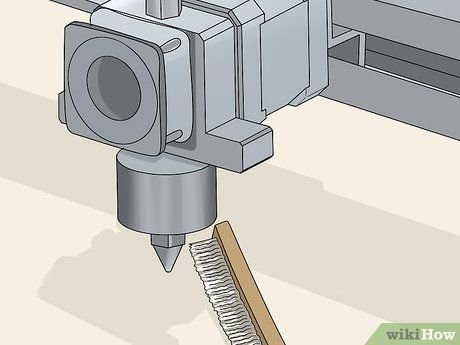

Scrub away any adhered material from the exterior using a wire brush. Keep the nozzle attached to the printer to ensure stability. Utilize back-and-forth strokes with firm pressure to remove any residual filament. Vary the angle and direction of brushing for comprehensive cleaning.

- Wire brushes are available at local hardware stores.

- Refer to the manufacturer's guidelines to confirm the compatibility of a metal brush with the nozzle.

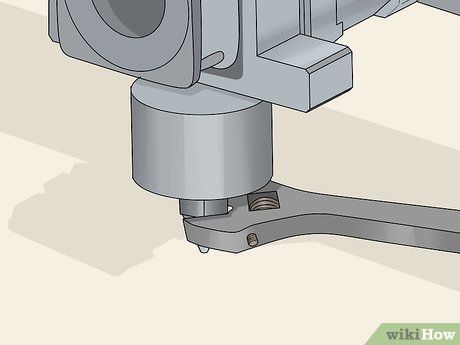

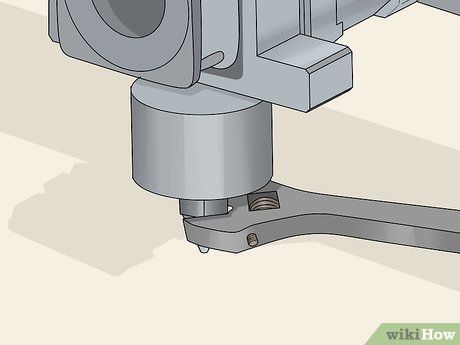

Raise the nozzle temperature to 150 °C (302 °F). Elevating the temperature aids in loosening the threads, facilitating easy removal. Set the temperature to a minimum of 150 °C (302 °F) to allow for expansion of the metal.

- Attempting to remove a cold nozzle may damage the threads, complicating reattachment.

Dismantle the nozzle using a wrench. Once heated, affix a wrench to the nozzle and rotate it counterclockwise for removal. Place the nozzle on a heat-resistant surface to prevent damage.

- Avoid direct contact with the nozzle to prevent burns.

Immerse the nozzle in acetone for 15 minutes, then air-dry. Submerge the nozzle entirely in acetone-filled container and allow it to soak for 15 minutes to facilitate breakdown. Afterwards, remove the nozzle from the acetone and dry it using a lint-free cloth or paper towel.

- Acetone, commonly found in nail polish removers, is available at local drugstores.

- Acetone aids in dissolving exterior contaminants and filament residue within the nozzle.

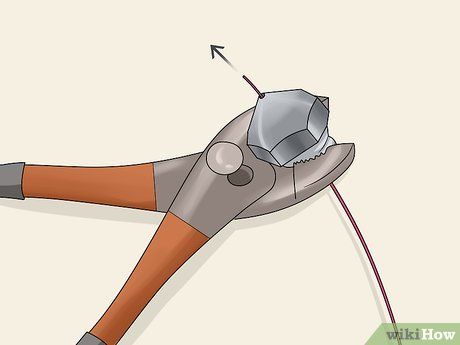

Warm the nozzle using a heat gun for 1 minute. Position the heat gun vertically and activate it. Secure the nozzle with pliers, holding it above the heat source. Rotate the nozzle to ensure even heating. The heat should help loosen any filament residue. After 1 minute, turn off the heat gun and set it aside.

- Heat guns are available at hardware stores.

- Avoid directing the heat gun towards anyone to prevent burns.

Clear any obstructions from the nozzle using a thin wire or needle. Grasp the nozzle with pliers and carefully insert a wire or needle into it. Scrape the inner sides of the nozzle to remove residue. Repeat the cleaning process until the obstruction is cleared and the nozzle is transparent.

- Clean the wire or needle if residue accumulates on them.

Tip: If the nozzle remains unclean after 2-3 minutes, reheat it to prevent filament solidification.

Recommendations

Cautionary Notes

Essential Supplies

Removing Blockages from the Nozzle

-

Clear ABS or nylon filament

-

Filament cutters

Performing a Thorough Cleansing with Acetone

-

Adjustable wrench

-

Stiff wire brush

-

Acetone solution

-

Lint-free cloth

-

Heat gun

-

Needle-nose pliers

-

Thin wire or needle