Plywood serves as a budget-friendly and adaptable material for construction, yet its porous nature poses challenges in outdoor applications. Waterproofing plywood significantly reduces the risk of warping or decay due to exposure to the elements. Discover the essential steps to prep your plywood and explore the top four methods to waterproof it effectively for prolonged outdoor use.

Key Considerations

- Opt for polyurethane varnish for reliable waterproofing, wood stain for weather resistance, oil for an economical sealant, or epoxy for enhanced durability.

- Prioritize sanding your plywood before applying any sealant to ensure proper adhesion. Ensure thorough coverage of the plywood surface with your chosen sealant for comprehensive waterproofing.

- Allow sufficient drying and curing time for the sealant to achieve optimal effectiveness.

Step-by-Step Guide

Prepping the Plywood

Establish a tidy workspace. Locate a level outdoor area devoid of any items susceptible to accidental paint spills. Arrange a surface for supporting the plywood during sealing, such as sawhorses, newspapers, or a clean wall.

Use a moist cloth to remove dust from the plywood. Prioritize surface preparation by wiping away debris that could hinder sanding. For rough plywood, employ a vacuum with a brush extension to clear debris.

Sand the surface with 180 to 220-grit sandpaper. Employ 180 to 220-grit sandpaper to stroke the plywood along the wood grain until achieving a smooth texture. Pay attention to sanding the sides and ends as well, using 80-grit sandpaper for particularly rough areas.

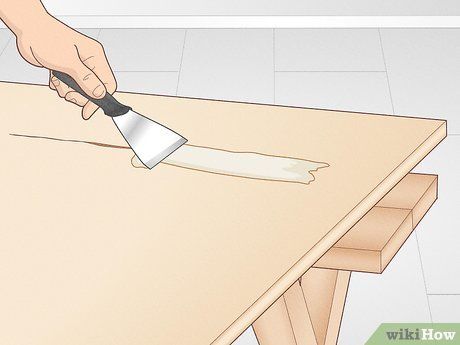

Inspect the plywood for divots and fill them with wood putty or filler. Apply putty or filler using a putty knife, ensuring complete coverage before scraping away excess material. Allow the putty to dry overnight before proceeding.

Sand and wipe the surface with a damp cloth to smooth the excess putty. After the putty or filler dries, use 220-grit sandpaper to sand the plywood again. Pay attention to areas where wood putty was used to ensure they are level with the rest of the board. Wipe the surface with a damp cloth to remove excess dust and debris, then let the plywood dry overnight.

Using Polyurethane Varnish for Plywood Sealing

Opt for polyurethane varnish for reliable waterproofing. This product offers good waterproofing and a nice finish at an affordable cost. It's easy to apply and doesn't require advanced skills.

Apply sanding sealer to both sides of the plywood. Prior to applying polyurethane sealer, prime the board with sanding sealer. Mix the sanding sealer, apply a thin coat with a paintbrush, and let it dry for about an hour. Sand both surfaces with fine-grit sandpaper, vacuum any sawdust, and wipe clean with a tack cloth or rag.

Use a clean paintbrush to coat the plywood with varnish. Apply varnish in long strokes along the wood grain to cover the board with a thin coat. Let the first coat dry completely, then apply a second coat. Repeat for both sides, allowing sufficient drying time between coats.

- Oil-based polyurethane varnish dries in about 6 hours, while water-based varnish may take up to 24 hours. Ensure proper drying time between applications based on the type of varnish used.

Apply varnish to the edges and ends. Use a smaller paintbrush to coat the ends and sides of the board with polyurethane varnish. Let each coat dry before applying the next. If you prefer a different finish on the broad faces, use a different sealant and protect the faces with masking tape.

Allow the varnish to cure for 30 days. Polyurethane varnish requires approximately a month to cure fully, so wait for this period before proceeding with your project or installing the boards outdoors.

Sealing Plywood with Water-Based Stain

Opt for a standard wood stain for general weather-proofing. Wood stains offer both protection and an attractive finish. They typically provide better sealing compared to regular paint.

Transfer the water-based stain into a garden sprayer. Garden sprayers, commonly used for pesticides, are suitable for applying sealants and stains to wood. Dilute the stain with water as instructed before pouring it into the sprayer.

Apply a layer of stain to both sides of the plywood. Use a garden sprayer to evenly apply the first coat of stain, ensuring complete coverage on both sides and edges. Allow the stain to dry for 10-15 minutes or as per instructions. After drying, wipe off any excess stain with a rag, then flip the plywood and repeat the process on the other side.

Allow the plywood to rest for 24 hours. Once the stain has dried for the recommended time, let the stained plywood sit for at least a day to cure. Apply additional coats as necessary to achieve your desired color and finish.

Using Oil for Plywood Waterproofing

Opt for oil as a relatively inexpensive and lightweight waterproofing solution. Oils are particularly effective for managing moisture and are well-suited for situations where heavy waterproofing is not required.

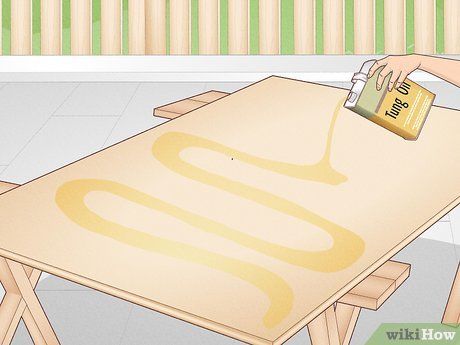

Choose from tung oil, boiled linseed oil, or mineral oil. Tung oil offers the highest water resistance and provides a durable finish, while boiled linseed oil and mineral oil are more economical options. You can mix oils, but ensure each layer dries completely before applying the next.

Apply oil onto the flat surface of the plywood. Lay the plywood flat to prevent oil from dripping off the edges. Pour oil generously onto the plywood and allow it to soak in for a few minutes. Add more oil until the entire board is saturated.

Massage the oil into the board, then wipe off the excess. Use a cloth or old T-shirt to remove excess oil while massaging it into less-saturated areas. Ensure thorough saturation by flipping the board and repeating the process on the back if necessary.

Sand the board and apply a second coat of oil. Sand the board with coarse sandpaper to create sawdust, then apply another coat of oil. Let the oil mix with the sawdust to fill the wood pores. No need to wait for drying as oil saturates the board before water can.

Using Epoxy to Seal Plywood

Opt for epoxy for a thorough and durable finish. Although time-consuming and costly, epoxy results in sturdy surfaces suitable for long-lasting fixtures like dining surfaces.

Prepare and apply epoxy on a warm, low-humidity day. Mix epoxy resin with a hardener according to the product instructions. Ensure suitable conditions for application, avoiding cold temperatures and high humidity.

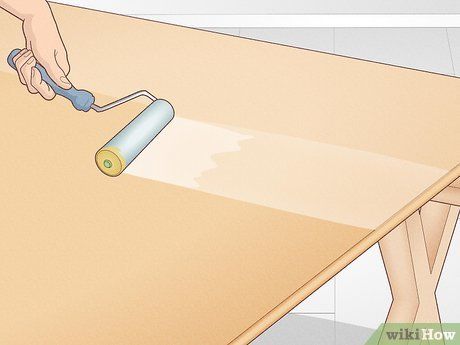

Use a roller to evenly apply the mixed epoxy. Pour a small amount onto the plywood and spread it thinly across the surface. Use a clean roller to flatten the epoxy and remove air bubbles.

Apply additional coats of epoxy. Wait until the previous coat becomes slightly tacky, then apply subsequent coats. Use a hair dryer to remove air bubbles as the epoxy cures.

Allow the epoxy to cure for at least a week. After applying the final coat, let the epoxy harden for one to two weeks. Keep the board dry and at room temperature during this period.

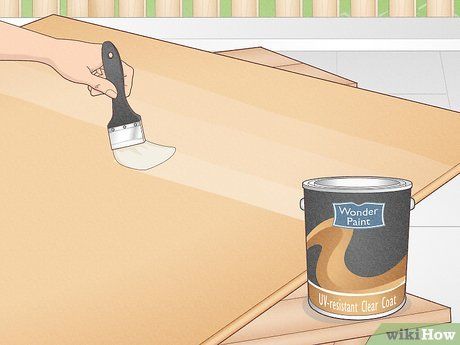

Protect the epoxy with a UV-resistant clear coating. Apply a UV-resistant top coat to shield the epoxy from UV rays. Use a paint roller or brush to ensure even coverage on all sides of the board.

Helpful Tips

Important Warnings

- Wear latex gloves and a face mask when handling wood sealants to protect your skin and respiratory system.

Essential Tools and Materials

- Sandpaper

- Damp cloth or rag

- Tack cloth

- Wood putty or filler

- Putty knife

- Paintbrush

- Paint roller

- Garden sprayer

- Vacuum

- Sanding sealer

- Polyurethane varnish

- Tung, linseed, or mineral oil

- Wood stain

- Epoxy

- Hair dryer

- UV-resistant clear coating, e.g., polyurethane paint or latex paint (optional)