A hydraulic jack serves as a device utilized for hoisting heavy loads, typically cars or trucks. Its functionality relies on oil to lubricate the internal mechanism. In the case of acquiring a new jack, it arrives devoid of oil, requiring filling. Additionally, jacks necessitate periodic oil refills. Initially, remove the cover plate and filler plug. Subsequently, fill the chamber with hydraulic jack oil. Finally, follow the procedure to purge excess air from the system, ensuring optimal functionality of your jack.

Procedures

Refilling the Hydraulic Jack with Oil

- Place the jack in an area tolerant of potential spills, such as the street, if avoiding oil stains on your driveway is desired.

- If unsure about your jack's release mechanism, refer to the owner's manual.

- Maintain an open release valve during the procedure.

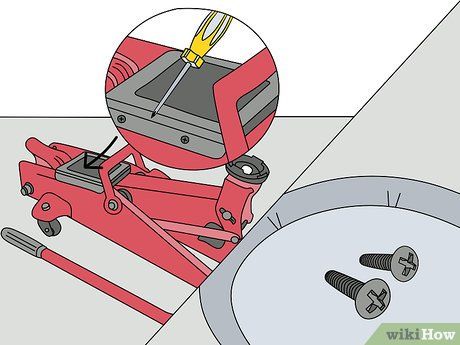

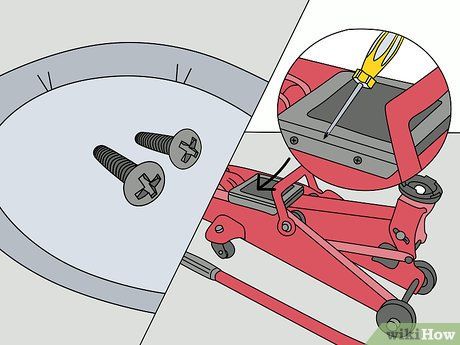

- Depending on the jack type, the cover plate may either fully detach or lift up. If removable, store it safely to avoid misplacement.

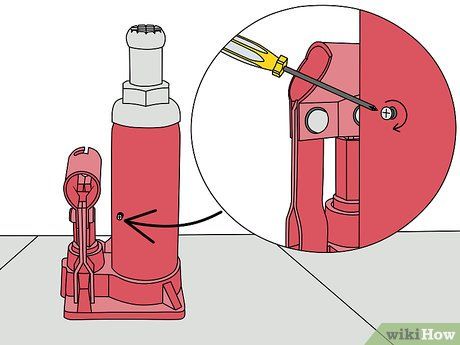

- Typically, Phillips head screwdrivers are suitable for removing these screws, but verify your specific model's requirements.

- Keep the removed screws safe for later reattachment of the cover.

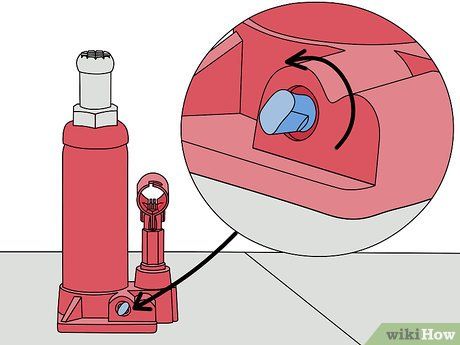

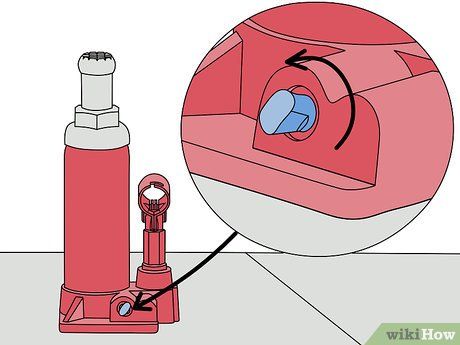

- For older jacks with accumulated dirt around the fill plug, consider using a hose or pressure washer to dislodge the debris beforehand.

- If unable to locate the filler port, consult the jack's owner's manual.

- Exercise caution to avoid damaging the plug during removal. If encountering resistance, halt and reassess rather than forcing removal.

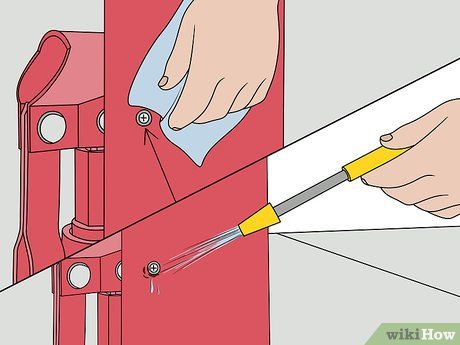

- Utilize a funnel to minimize spillage.

- Strictly employ hydraulic jack oil for this purpose; other oils such as motor oil or brake fluid are not suitable.

- Delay replacing the cover plate for now. Air bleeding remains necessary before proceeding, and the cover plate could hinder the process.

- Depending on your jack model, it might be necessary to keep the fill plug out during air bleeding. Refer to your owner’s manual for the correct procedure.

Air Bleeding Procedure

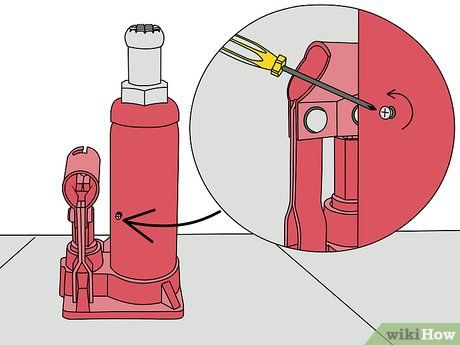

- Air bleeding is vital to remove air buildup in the hydraulic system, which can impede proper jack operation. Failure to bleed air might result in improper lifting or even jack failure.

- Various jack models may have different air bleeding methods. Consult your owner’s manual to ascertain the appropriate procedure for your model.

- If the jack operates jerkily or fails to reach its full height, air likely remains in the system. Repeat the air bleeding process if necessary.

Essential Supplies

- Screwdriver (flathead or Phillips)

- Hydraulic jack oil

- Rags

Useful Pointers

Important Reminders

- Only utilize hydraulic jack oil for your jack; using any other liquid can lead to jack failure.

- Prior to performing maintenance on your jack, always refer to your owner’s manual as different models may feature distinct mechanisms.