Marvel Schebler carburetors are commonly found in vintage gas tractors, especially Minneapolis Moline tractors. If your tractor fails to start or doesn't run smoothly, the issue often lies within the carburetor. As time passes, carbon accumulates and internal components wear down, reducing the carburetor's ability to distribute fuel effectively. Follow these steps to understand how to clean and rebuild a Marvel Schebler Carburetor.

Procedure

Dismantling

Set up a tidy workspace. Maintaining a clean workspace is crucial while working on the carburetor as even the slightest speck of dirt can clog up the system and lead to issues. Ensure to lay down paper towels or newspaper before commencing work.

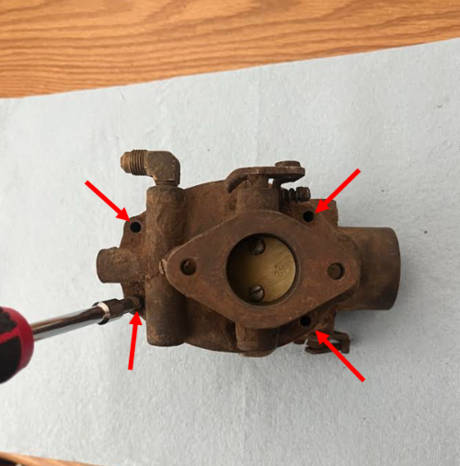

Detach the bottom needle assembly. For type C carburetors, you'll find this at the bottom. It comprises three pieces. Unscrew the needle manually, then use an adjustable wrench to remove the needle seat. Finally, employ a large flat screwdriver to extract the internal tube.

Extract the idle adjusting needle and its spring. Situated on top, use a flat screwdriver to take it out.

Take off the upper component. Secured by four screws at the carburetor's corners, remove them to detach the top. Be careful not to harm the float or misplace any internal components.

Detach the float. Secured by a sliding pin, it can be removed manually.

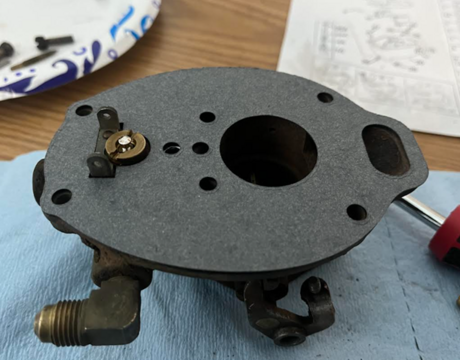

Scrape away the old gasket. Often, the old gasket sticks to the carburetor. It needs removal to ensure a snug fit for the new gasket. Use a screwdriver to scrape off any remaining gasket and residue from the edges of both pieces.

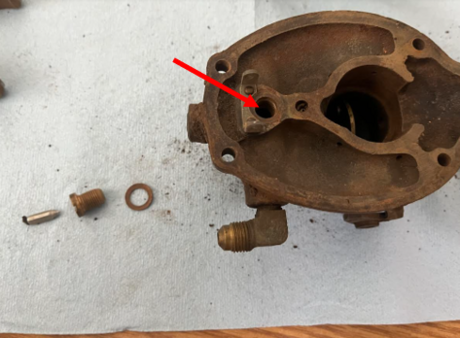

Detach the venturi. Positioned at the center of the bottom piece, the venturi is crucial for ensuring proper fuel flow. Handle it carefully to avoid loss or damage.

Extract the needle, seat, and gasket assembly. This assembly is highly significant, typically included in a rebuild kit. Remove the small spring manually, then invert the top to access the needle. Use a large flat screwdriver to unscrew the needle seat. Beneath it, you'll find a rubber or felt gasket washer that also needs removal.

Remove the idle jet. Situated just behind the needle, seat, and gasket assembly, use a very small screwdriver for removal. Exercise caution as these components are delicate and prone to breakage.

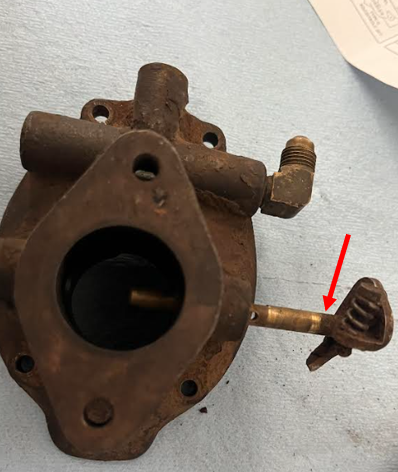

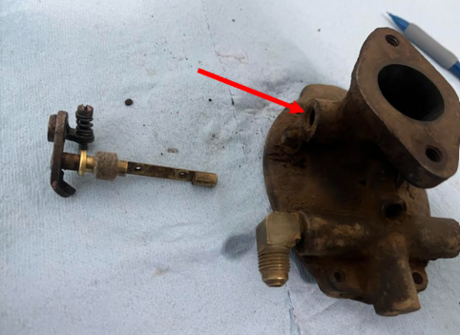

Detach the throttle valve. Located in the hole through the top piece, the throttle valve is secured by two screws. Use a small flat screwdriver to remove them.

Extract the shaft and lever assembly. Once the throttle valve is removed, slide out the throttle shaft and eliminate any remaining gaskets in the holes.

Unscrew the drain plug. Adjust the drain plug at the bowl's base to the open position, allowing fluids to drain out during the cleaning procedure.

Cleansing

Thoroughly clean all components. Utilize carb cleaner and paper towels to clean both carburetor pieces and all internal parts. Ensure carb cleaner is sprayed into every orifice to prevent blockages. Eliminate all rust and carbon deposits.

(Optional) Soak internal components overnight (optional). If the internal parts are heavily soiled, soak all metal pieces in a cleaning solution such as bleach, toilet bowl cleaner, or carb cleaner.

Reassembly

Reconstruct the throttle shaft assembly. Install a fresh felt gasket and brass retainer onto the shaft, then reinsert it into the hole.

Attach the throttle valve. Place the throttle valve back into the hole, ensuring it's angled correctly for fitting. Insert the two screws into their respective holes. Using a small magnetic flat screwdriver is recommended as these screws are small and angled.

Reinstall the idle jet. After confirming all threads are clean, screw the idle jet back into place. Tighten until snug, but avoid over-tightening to prevent breakage.

Install the new needle, seat, and gasket assembly. These components are typically included in the rebuild kit. Place the new gasket washer over the needle seat and screw them into position. Carefully drop the needle into the seat, ensuring the tip remains undamaged. Slide the spring over the needle to secure it in place.

Position the venturi in the bowl. Reinsert the venturi into its designated spot. It should fit snugly without forcing it in as it only fits one way.

Position the new gasket correctly on the top piece. Ensure the new gasket is aligned properly and nothing protrudes, as it can be easily damaged. A faulty gasket may lead to leaks and allow dirt and grime to enter the carburetor.

Secure the new float. Attach the new float by inserting the pin through the holes. Adjust the float until it lies parallel with the other components. Avoid excessive angling, as it may impede proper fuel flow.

Tighten the top piece. Reattach the top piece using the four screws and ensure a snug fit. Handle the assembly gently to prevent damage to the float or gasket.

Install the new upper needle and spring. Use the provided needle and spring from the rebuild kit. Screw the needle all the way in, then back out one and a half turns.

Install the lower needle assembly. Reassemble the bottom assembly by first inserting the tube, followed by the needle seat, and then the needle. Tighten the needle completely, then back it out one and a half turns.

Helpful Tips

-

Ensure to utilize the appropriate size screwdriver for removing parts, especially considering some are delicate and made of brass, thus prone to breakage.

-

When adjusting the carburetor, tighten the top needle completely, then back it out one and a half turns. Repeat this process for the bottom needle.

-

Upon reattaching the carburetor to the machine, fine-tune the needle adjustments while the tractor is operational until it runs smoothly.

Important Warnings

- Always use appropriate safety gear like rubber gloves when handling cleaning solutions.

- Exercise caution regarding where carb cleaner is applied as it possesses high corrosive properties.

Essential Tools

- Paper towels or newspaper

- Screwdrivers of different sizes and types

- Carburetor cleaner

- Protective rubber gloves