Plastic fuel tanks are highly sought after in the realm of motorcycle racing and ATV enthusiasts. They weigh less than half of their metal counterparts and can be easily shaped to fit unique configurations. Seamless fuel tanks rarely leak and are resistant to the rust and corrosion that affect metal tanks. If a plastic fuel tank sustains small holes or tears, there are several relatively simple methods to effect repairs.

Steps

Seal a Plastic Fuel Tank Using Epoxy Adhesive

Empty the gasoline from the tank and let it dry completely. Sand the area around the hole or crack, and wipe it clean with a shop cloth soaked in rubbing alcohol.

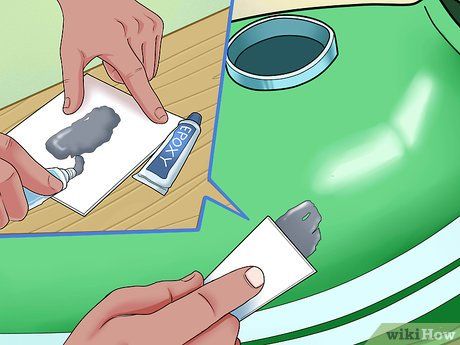

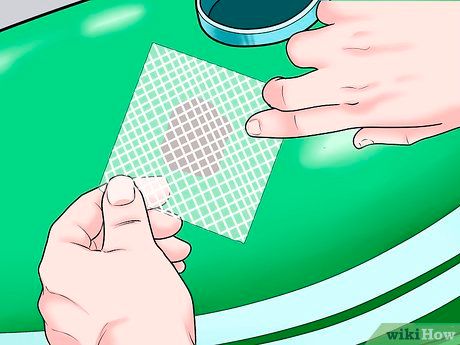

Combine the two-part epoxy and spread it evenly around the edges of the opening. Cut a fiberglass patch large enough to cover the hole with some overlap.

Position the fiberglass patch over the hole and press it firmly onto the epoxy. Apply additional epoxy over the patch and surrounding area, pressing down firmly to ensure saturation.

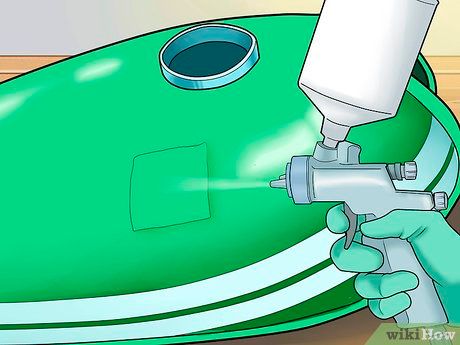

Allow the epoxy to dry completely, then sand the patched area smooth. Optionally, you can spray paint the patched area with plastic paint for a finished look.

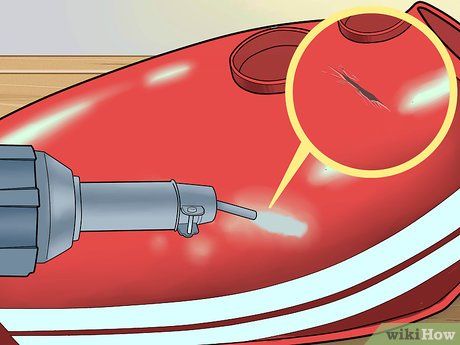

Seal a Plastic Fuel Tank with a Plastic Welder

Purchase or rent a plastic welder. Inform the salesperson about your project to ensure you receive the appropriate rods for the job.

Detach the plastic gas tank from the vehicle and place it in a secure welding space. Empty the tank of gasoline and ensure both the interior and exterior are completely dry. Wear protective eyewear, a welding helmet, and welding gloves.

Utilize a specialized plastic welding rod to fill the crack or gap. Begin at one end and carefully work the bead around the entire perimeter of the opening. Then, proceed to crisscross over the hole, allowing the rod to fill it entirely.

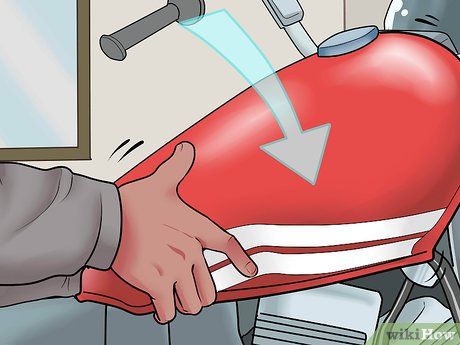

Allow the weld to cure, then sand it smooth and, if preferred, apply plastic spray paint for a polished finish.

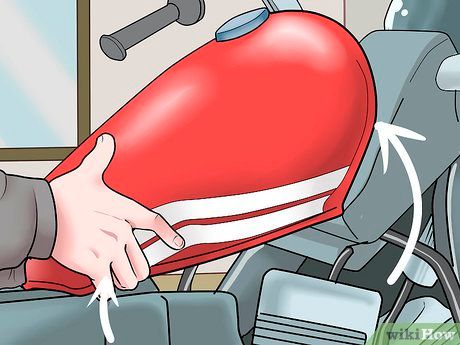

Reinstall the repaired plastic fuel tank onto the vehicle.

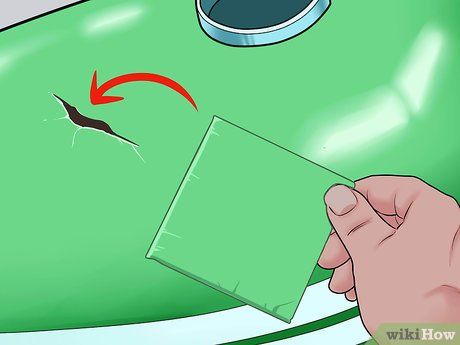

Seal a Plastic Gas Tank with a Soldering Gun

Empty the fuel tank and thoroughly clean it with soapy water. Gently sand the area around the repair site.

Cut a plastic patch, using a material similar to the gas tank, slightly larger than the damaged area.

Heat an electric soldering gun and carefully create a trench along the crack's edge. Move the gun back and forth to push the plastic into the trench. While the plastic is still soft, place the patch over the damaged area. Continue using the soldering gun to smooth and fuse the plastic together.

Allow the repair to cool and dry completely. Prepare a 2-part epoxy glue and apply it over the entire patch. Let it set, then sand the area and apply a coat of plastic paint if desired.

Helpful Tips

- Epoxy glue offers an easy solution for sealing plastic fuel tanks, although it may sometimes fail prematurely.

- If you're using a plastic welder for the first time, it's wise to practice beforehand. The rental store can assist you in ensuring a smooth experience.

Important Warnings

- A plastic welder is generally safe to use around gasoline and its fumes due to its high flash point. However, avoid using it near open flames and exercise caution.

Essential Supplies

- Plastic patches

- 2-part epoxy glue

- Fiberglass patch

- Sandpaper

- Shop cloth

- Rubbing alcohol

- Plastic spray paint

- Plastic welder

- Welding rods

- Welding helmet

- Welding gloves

- Eye protection

- Soldering gun