If you find yourself needing to remove your car's tire for a flat change, rotation, or repairs, the first step is to take off the lug nuts. Safety is paramount, so ensure you execute this task carefully to avoid any mishaps. With a few safety measures and a steady pace, you can safely and efficiently remove your tire.

Procedure

Disassembling a Raised Wheel

Utilize the appropriate tool to loosen the lug nuts. Before lifting the vehicle, use a wrench or tire iron to loosen the lug nuts. Avoid completely removing them; instead, turn them a quarter turn counterclockwise to loosen them sufficiently for removal once the vehicle is elevated.

- You can procure tire irons from local auto parts stores, often equipped with a universal fitting end.

- Alternatively, opt for a deep socket of the correct size with a ratchet or breaker bar.

- If a lug nut proves stubborn, apply pressure on the tire iron to dislodge it.

Detach the lug nuts. Since the lug nuts were already loosened prior to lifting the car, they should now be relatively easy to unscrew completely. Utilize a wrench if necessary to turn the lug nuts counterclockwise until they detach from the lug studs.

- As you remove the lug nuts, be mindful of potential wheel movement to avoid finger pinches.

- Remove the lug nuts in a crisscross pattern rather than sequentially to ensure even disengagement.

Apply a thread loosener if required. In case the lug nuts are corroded, generously apply a thread loosening solution or rust remover onto the nuts. Allow it to sit for a few minutes before attempting to loosen the lug nut again.

- If a lug nut and stud break, professional repair involving installation of a new lug stud is necessary.

- Ensure usage of the correct sized socket to prevent rounding off the lug nut.

- If a lug nut is stripped or rounded, seek professional assistance for removal.

Safely store the lug nuts. Place the lug nuts in a secure location to prevent loss. Losing a lug nut may allow temporary securing of the wheel with remaining nuts, but losing multiple nuts renders the vehicle unsafe to drive until replacements are obtained.

- Replacement lug nuts can be acquired from local auto parts stores.

- Utilize a small bowl or container to prevent lug nuts from rolling away during work.

Extract the wheel towards you. Once the lug nuts are removed, grasp the tire from both sides and pull it towards you to disengage it from the lug studs. If the wheel hasn't been removed for a while, considerable force might be necessary to detach it.

- Exercise caution, especially if the tire is damaged and has protruding metal wires that can cause injury.

- Wearing gloves is advisable when dealing with damaged tires.

Utilize a rubber mallet to loosen stubborn wheels. If the wheel is firmly stuck and doesn't yield to pulling, employ a rubber mallet to dislodge it. Strike the tire around the rim-tire junction in a circular motion until it loosens.

- Avoid using a metal hammer on rims to prevent damage.

- Considerable force might be required to free a rusted wheel.

Elevating a Wheel

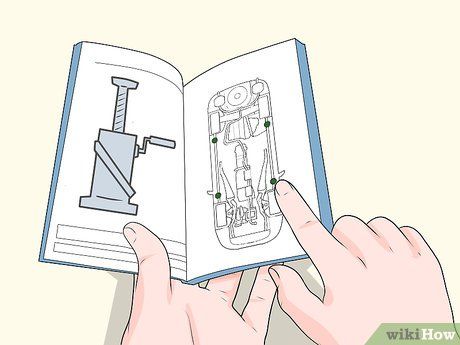

Identify the designated jack points on your vehicle. Each vehicle has specific points on its frame designed to bear the weight of lifting. These points might not be readily apparent, so consult your vehicle’s manual if you have trouble locating them.

- Typically, jack points are situated inside each wheel and at central positions on the front and back of the vehicle.

- Using improper jacking points can result in damage to the vehicle's frame.

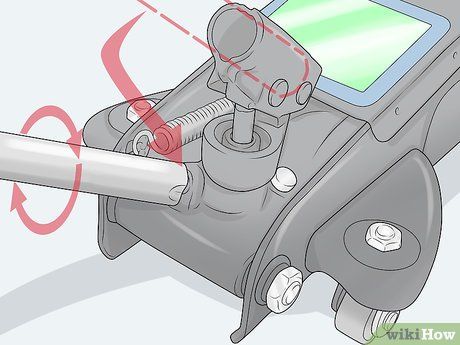

Secure the jack valve. Hydraulic trolley jacks operate by building pressure to lift the vehicle. Ensure the hydraulic valve is fully closed by turning it clockwise using the jack handle. Reinsert the handle into the jack once the valve is closed, if applicable.

- The valve may be positioned differently depending on the jack, often distinguished by color or being unpainted.

- If using a scissor jack, there's no valve to close.

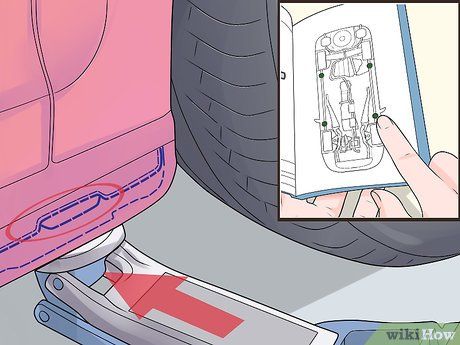

Position the jack under the appropriate jack point. Slide the jack beneath the nearest jack point to the wheel you're working on, ensuring the cup of the jack is positioned just under the frame. Adjust the jack if needed to ensure proper alignment.

- The jack's cup should align centrally with the designated jack point.

- The cup may have teeth or ridges to prevent sliding as the vehicle is lifted.

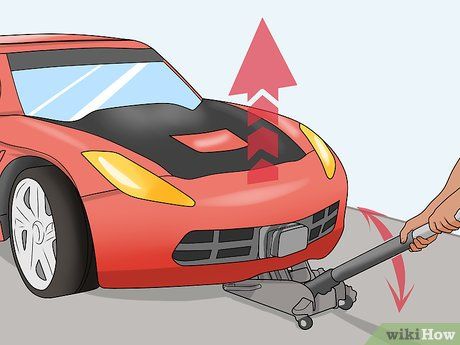

Lift the vehicle using the jack. Depending on the jack type, use the handle to raise and lower (with a trolley jack) or turn (with a scissor jack) to elevate the vehicle. Begin lifting slowly, monitoring the frame around the jack point for any signs of metal bending or crimping.

- If bending is observed, lower the vehicle and readjust the jack positioning.

Only raise the car to the necessary height. Jacking a vehicle too high increases the risk of it slipping off the jack or stands. Elevate it only enough to facilitate tire replacement, and promptly place jack stands for added safety.

- Avoid placing any body part beneath the vehicle without jack stands for support.

- Lift the vehicle until the tire clears the ground for removal.

Preparing to Utilize the Jack

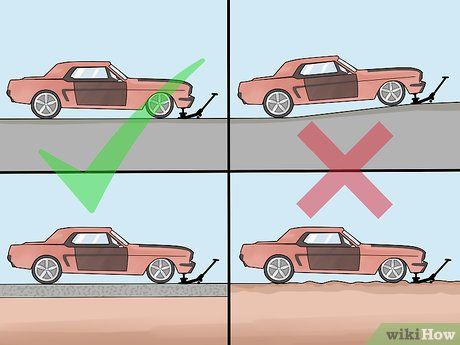

Choose a stable, level surface for jacking. When lifting a section of the car, the weight is concentrated on the jack's small contact area. Ensure the surface can withstand this pressure. Concrete and asphalt are ideal. Avoid jacking on angled surfaces for safety.

- Never jack on uneven or sloped surfaces.

- Insufficiently strong surfaces can cause the jack to collapse or sink.

Ensure ample workspace for safe operations. Whether using an emergency or trolley jack, ensure enough space to work without endangering yourself or others. Have sufficient space to stand without obstruction, especially if replacing a flat tire.

- Ensure there's space behind the jack without impeding traffic.

Verify the car is in park. For automatic transmissions, engage park before jacking. This prevents wheel rotation and potential rolling. Use wheel chocks alongside park mode to secure the vehicle.

- Parking locks the drive wheels; front-wheel drive cars' front wheels won't turn, and vice versa for rear-wheel drive.

- In manual transmissions, consider first gear to prevent rolling.

- Wheel chocks, bought from auto parts stores or improvised from rocks, prevent wheel movement during lifting.

Activate the parking brake. Depending on your vehicle's type, the parking brake may be a lever in the center console or a pedal on the left side while seated in the driver's position. Pull up the lever or push down the pedal to engage the parking brake, preventing the vehicle from rolling during jacking.

- Refer to your owner’s manual for guidance if you're uncertain about locating the parking brake.

- The parking brake secures the rear wheels, thus it won't be effective if the entire rear section of the car is raised.