You can employ a tap to create threads within a metal-drilled hole, such as steel or aluminum, facilitating the insertion of a bolt or screw. The procedure for tapping a hole is actually quite straightforward, but it’s crucial to execute it correctly to ensure even and consistent threads and holes. Select a drill bit and tap that match the size of the screw or bolt you intend to use, ensuring they are of identical size. For safety measures, it’s imperative to stabilize the object being drilled and utilize the appropriate drill bits.

Procedures

Creating the Hole for the Threads

Opt for a tap and drill set in the appropriate size. Tap and drill sets comprise drill bits and taps that are compatible with each other, enabling you to drill a hole with the bit and subsequently utilize the corresponding tap to add threads. Seek out a set that encompasses both taps and drill bits at your nearby hardware or home improvement outlet.

- You can also procure tap and drill sets online.

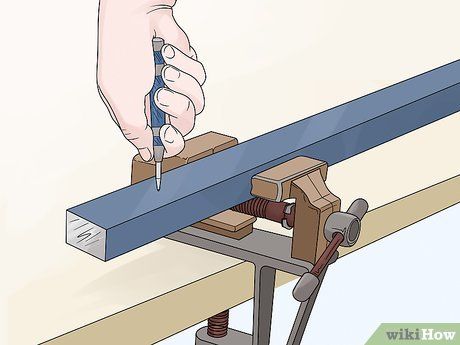

Secure the metal firmly in place using a vise or C-clamp to prevent any movement. A moving metal surface could cause the drill bit to slip off, potentially resulting in injury. Place the metal securely in a vise or attach a C-clamp to hold it steady.

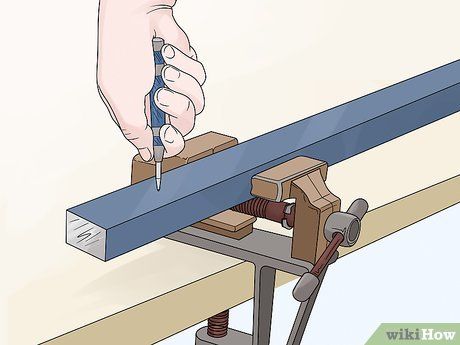

Utilize a center punch to create a small indentation at the drilling point. A center punch is a tool designed to create an indentation in a surface, enhancing the drill's grip and effectiveness. Use either an automatic center punch or a regular one to create the indentation.

Insert the drill bit into the drill's chuck. Place the drill bit into the chuck and tighten it securely to hold the bit in place.

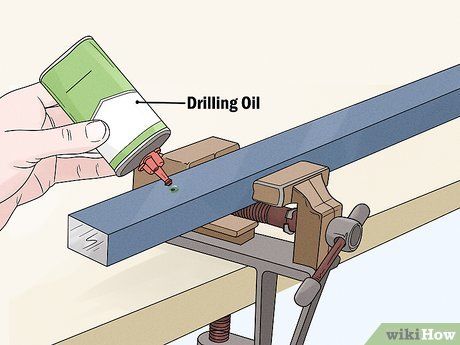

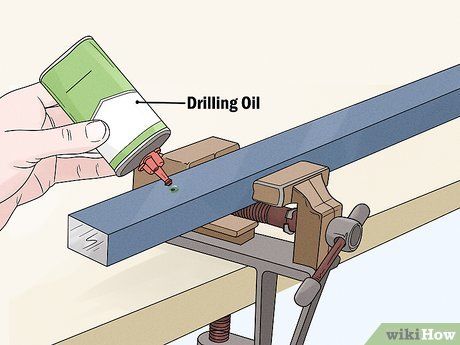

Apply drilling oil to the indentation. Drilling oil, also known as cutting oil, lubricates the drilling process, reducing heat and friction. Apply a drop of oil directly into the indentation to facilitate smoother drilling.

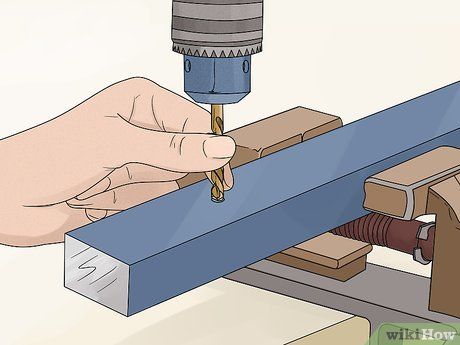

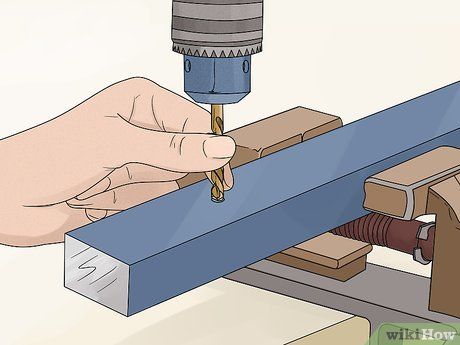

Position the drill bit into the indentation and begin drilling gradually. Align the drill over the indentation, ensuring the bit is perpendicular to the surface. Apply gentle pressure and start drilling slowly to initiate the drilling process.

Operate the drill at a moderate speed and maintain steady pressure. Gradually increase the drill's speed as it cuts into the metal. Keep the speed within the medium range and apply consistent pressure without exerting too much force.

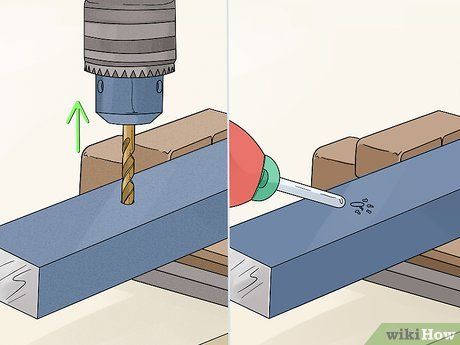

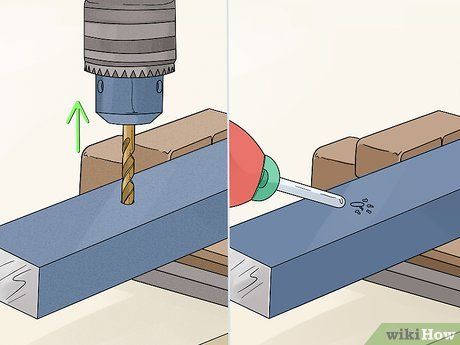

Periodically withdraw the drill every 1 inch (2.5 cm) to clear away metal flakes. Metal shavings can increase friction and heat up the drill bit, leading to uneven holes. Pause drilling intermittently to remove accumulated metal flakes and shavings, ensuring smooth and uniform hole formation.

Creating Threads in the Hole

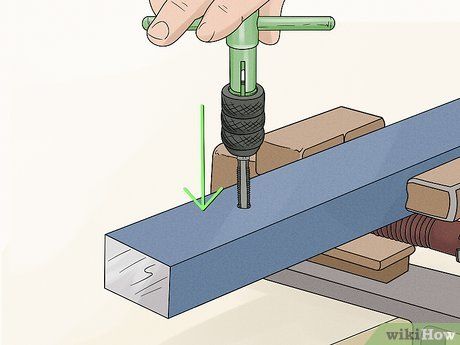

Insert the appropriate tap into a T-handle for manual threading. Securely fasten the tap into the T-handle device, which facilitates the manual creation of threads in the drilled hole, essential for accommodating screws and bolts.

Lubricate the hole with drilling oil. Apply a few drops of drilling oil directly into the hole to facilitate the tapping process and thread creation. Wipe off any excess oil with a clean cloth to ensure a tidy workspace.

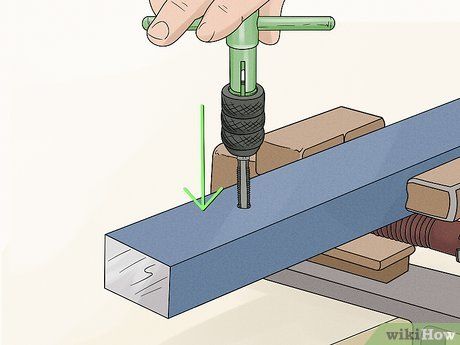

Ensure the tap is inserted straight into the hole. Position the tap to align perfectly with the drilled hole, ensuring it enters straight to create threads in the correct alignment.

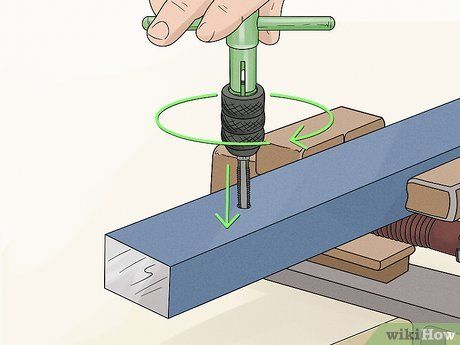

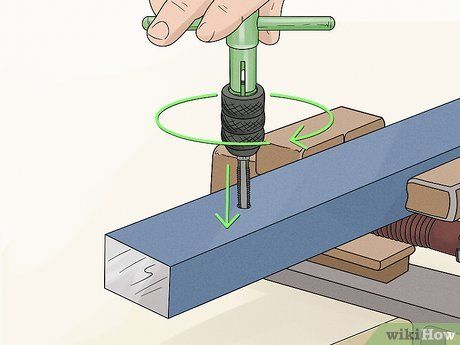

Thread the hole using the T-handle and tap. Rotate the T-handle clockwise to initiate the tapping process, maintaining smooth and consistent rotations. Avoid applying excessive pressure to ensure even and uniform threading of the hole.

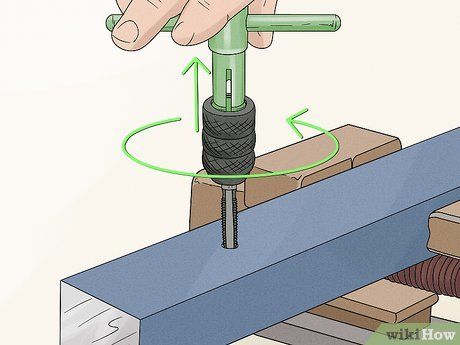

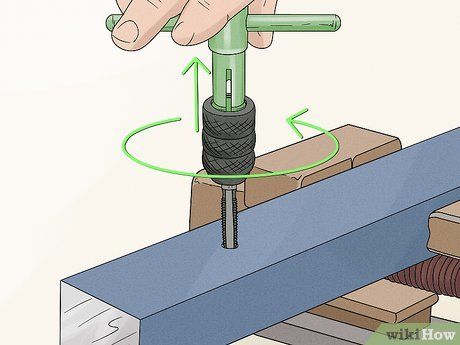

Remove the tap by reversing the T-handle rotation. Rotate the T-handle counterclockwise until the tap protrudes from the opposite side of the hole. Then, gently turn it in the opposite direction to extract the tap from the hole.

Useful Tips

Take your time during drilling and maintain steady, gentle pressure on the drill. Rushing the process can result in uneven holes and threading.

Essential Tools

- Power drill

- Tap and drill set

- T-handle

- Drilling oil

- Automatic center punch

- Vise or C-clamp

The content is developed by the Mytour team with the aim of customer care and solely to inspire travel experiences. We do not take responsibility for or provide advice for other purposes.

If you find this article inappropriate or containing errors, please contact us via email at [email protected]