If you love off-roading, you're probably familiar with the desire to stand out from the crowd. Whip lights offer a fantastic way to showcase your style wherever your adventures take you. These LED light tubes, reminiscent of flags, adorn dirt bikes, ATVs, 4x4s, motorcycles, and even trucks. They're surprisingly easy to install, even for those with limited mechanical experience. Simply wire them to your vehicle’s battery and illuminate the trails with your unique colors.

Steps

Mounting the Base Light

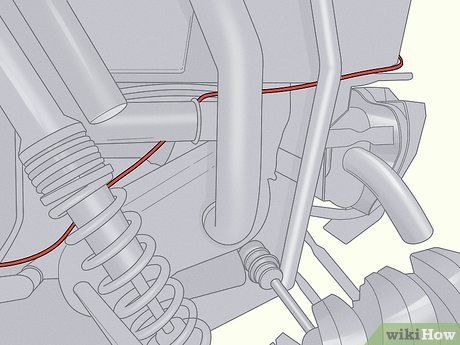

Find a suitable hole on the rear end of your vehicle's frame. Nowadays, many vehicles, including trucks and ATVs, come with pre-existing spots for mounting whip lights. Explore the back end of your vehicle, inspecting the bumper for holes. These may be concealed by bolts but should remain free of wires or other obstructions. Most vehicles offer multiple mounting points for a quick and easy installation of your new, stylish lights.

- Alternatively, you can drill a hole through the vehicle's frame. For instance, if you're working with a truck, consider drilling through its bed. Position the whip light over the hole, ensuring the power lights hang beneath it.

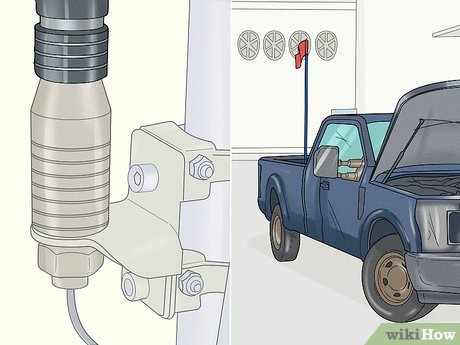

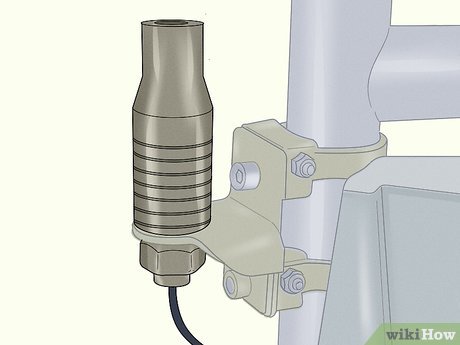

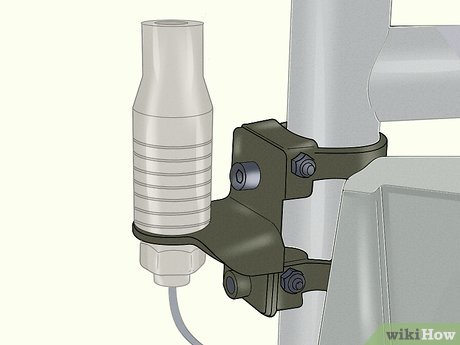

- If your vehicle lacks accessible frame holes, utilize mounting brackets instead. Identify areas on the frame to attach the brackets, such as an ATV's roll cage.

- Many off-road vehicles feature holes intended for flagpoles. If your vehicle boasts such a hole, it serves as an ideal location for installing a whip light.

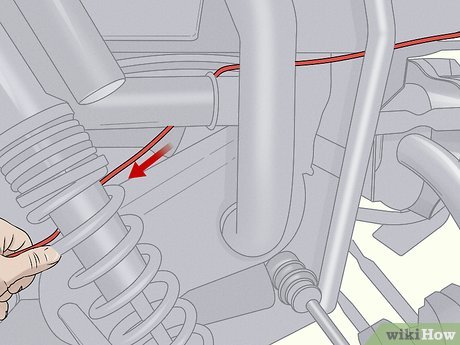

Use a socket wrench to unscrew the bolt covering the hole. Typically, there will be a metal bolt secured through the hole with a locking nut underneath. Reach beneath the hole to access the nut and turn it counterclockwise until it can be slid off the bolt. Then, switch the socket wrench to the top of the bolt and rotate it counterclockwise to remove it. If the rear bumper obstructs your access, remove it by unscrewing the bolts located around the frame's edges.

Detach the base of the whip light by turning it counterclockwise. Each whip light features a black plastic base at one end. Twist the base counterclockwise by hand to detach it. Set the whip light aside for later use. Removing the base makes mounting and wiring much simpler without the light getting in the way. While removing the base, place the light on the ground, such as on a clean towel, to prevent accidental drops.

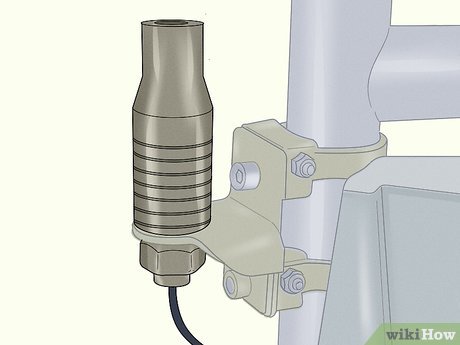

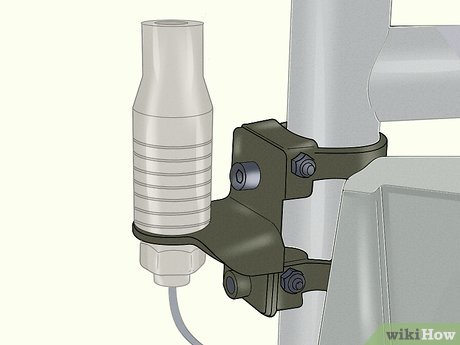

Position the whip light base atop the hole for mounting. Guide the power cord, extending from the bottom of the base, through the hole. Ensure that the quick-connect base sits flat against the frame. Then, reattach the nut to the base's bottom and tighten it clockwise. The base should rest above the hole, with the power cord tucked underneath along the frame.

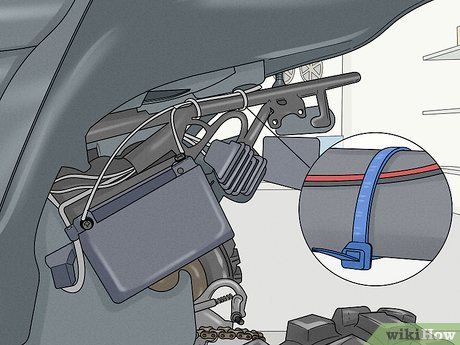

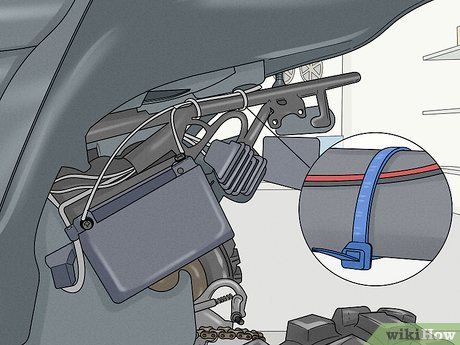

Attach mounting clips to the frame for an alternative installation location. Various types of mounts are available, with common ones being rings that clip onto different parts of the vehicle. Remove the screws from the clips and affix them to a suitable spot, such as the roll cage or another exposed bar on the frame. Insert the whip light base into the mounts and secure it in place by replacing the screws and nut. One potential mounting spot for the clips is the outer edges of an ATV's roll cage, positioned just above the vehicle's frame. While most mounting clips hang vertically, there are horizontal options available as well. If you intend to connect the lights to a horizontal bar, opt for horizontal clips, ensuring the lights rise straight up into the air when installed.

Routing Wiring to the Battery

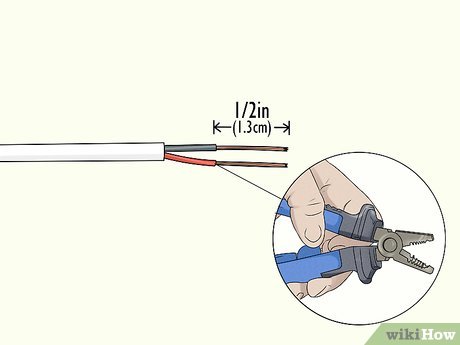

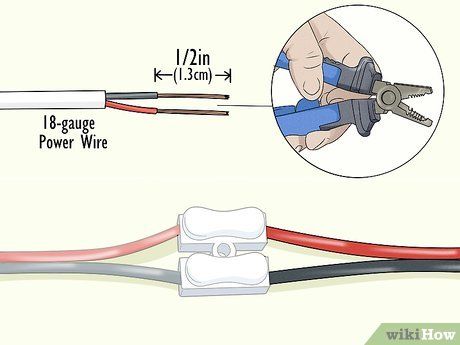

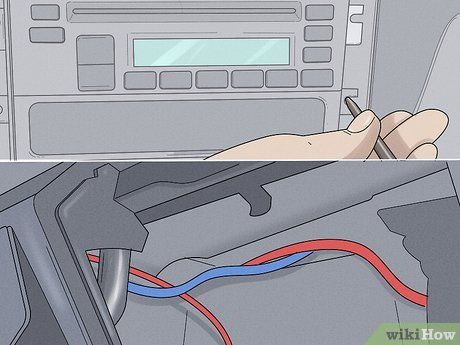

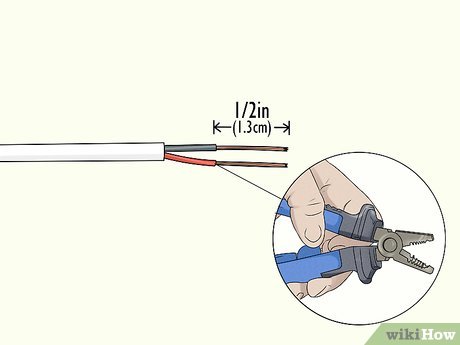

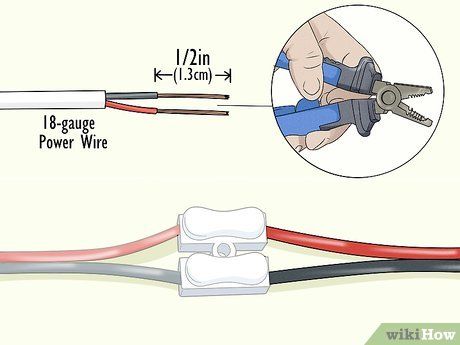

Trim 1⁄2 inch (1.3 cm) off the ends of the power wires on the light. The wires may be too short to reach your vehicle’s battery, but you can extend them by splicing in additional wiring. Typically, the base includes a red wire and a black wire. Use wire strippers to expose a small length of copper wire at the end of each wire.

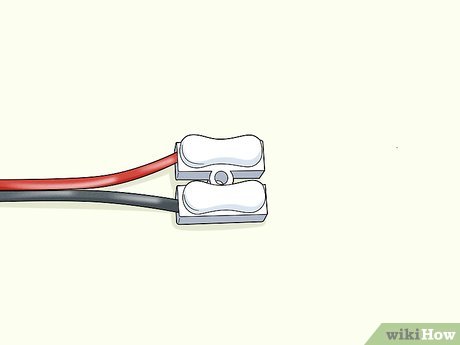

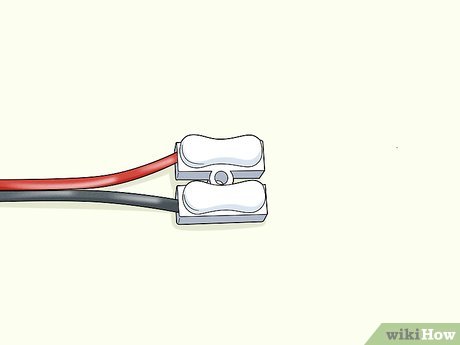

Insert the stripped power wires into a quick connector for splicing. Quick connectors cover exposed wires and facilitate easy connections to other wires. Choose a quick disconnection with terminals to plug the wires into. Push the exposed copper wires from the cable into the terminals.

Attach 18-gauge power wires to the opposite end of the connector. Use wiring that matches the colors of the wires from the whip light base, typically a black and red wire. Strip 1⁄2 inch (1.3 cm) of casing from each wire and connect them to the corresponding terminals in the connector.

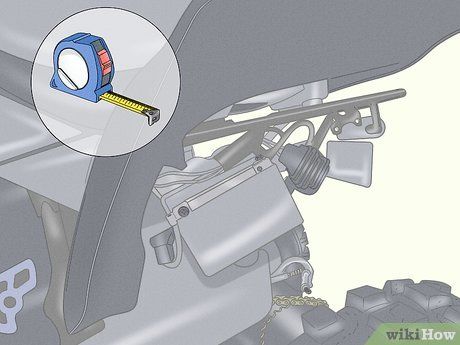

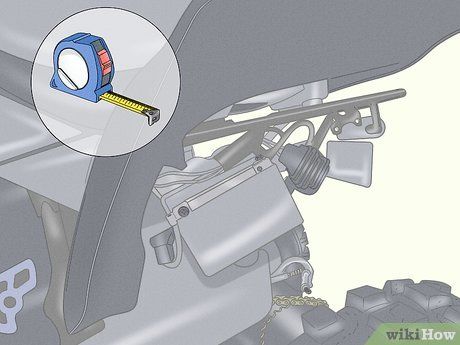

Measure the distance from the lights to the battery for the wiring. Estimate the length needed using a tape measure. It's advisable to cut the wire longer than needed to account for routing along the vehicle's frame.

Cut the 18-gauge power wires to the measured length using pliers. Use lineman’s pliers or wire cutters to cut both the red and black wires to the same length. Do not strip off the casing until after routing the wires.

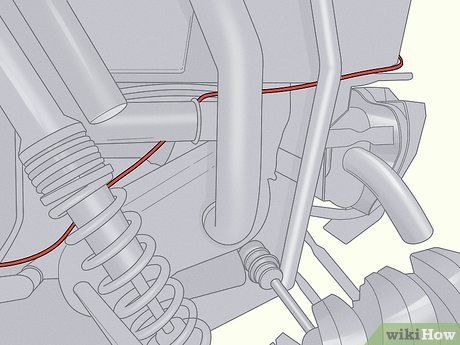

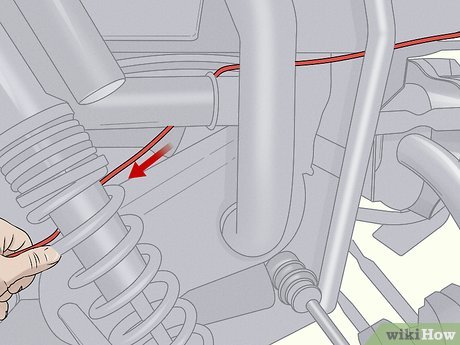

Route the 18-gauge wires to the battery for compact ATVs. Locate the battery underneath or behind the seat. It's often exposed, making it easy to connect the wires directly. Before connecting, loop the wires around the frame to protect them from damage.

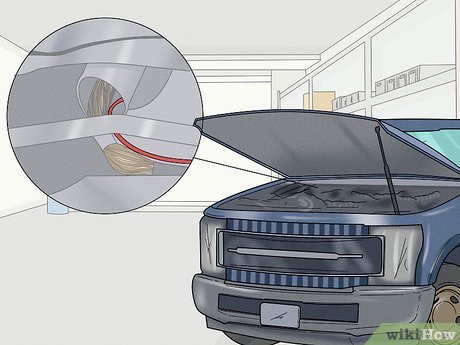

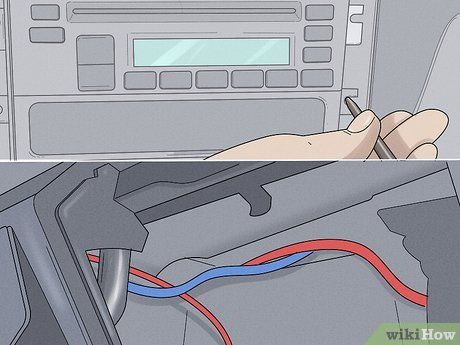

Thread the 18-gauge wires through the rear end for larger vehicles. Look for an opening beneath the vehicle leading to the rear seats. Pass the wires through this opening into the cab. Check inside to ensure they've reached the interior. If accessible, remove the bumper to track the wires more effectively.

Pull the wires along one side of the vehicle towards the front. From inside the cab, locate the wires and draw them forward, keeping them along a single side. If possible, run them along the exposed frame or tuck them under carpeting.

Installing an Inline Fuse

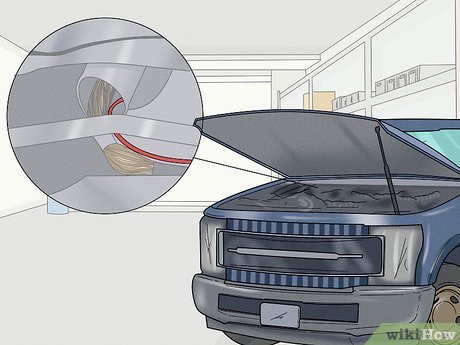

Access the battery by opening the hood or front cover on larger vehicles. For trucks, lift the hood. Other vehicles, like ATVs and 4x4s, may have a removable cover in front of the dashboard. Remove the cover using a Torx screwdriver to expose the battery.

Remove the dashboard, seats, and other components in trucks and large ATVs. Identify the push pins atop the dashboard and pull them out using pliers. Gently pull the dashboard forward and disconnect any attached wires. Look for a hole to route electrical wires through the dashboard; if not found, remove parts like seats and console with a Torx screwdriver for extra space.

Thread the light's power wires through an opening in the engine compartment. Guide the cable along your vehicle's sides towards the dashboard. Use a flashlight to locate a small hole, often covered with a rubber plug, on the dashboard or center console.

Use wire strippers to trim 1⁄2 in (1.3 cm) of insulation from each wire. Expose the wires carefully for connection to the vehicle's power supply. Twist the exposed copper strands together and insert them into an electrical connector.

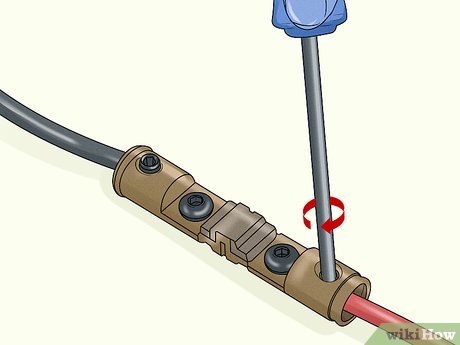

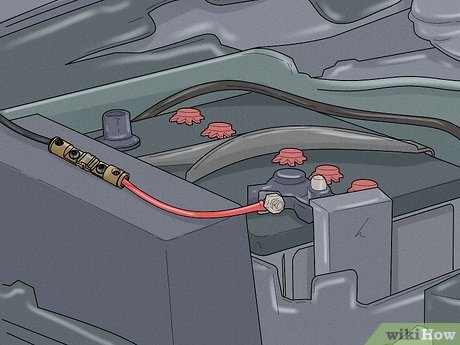

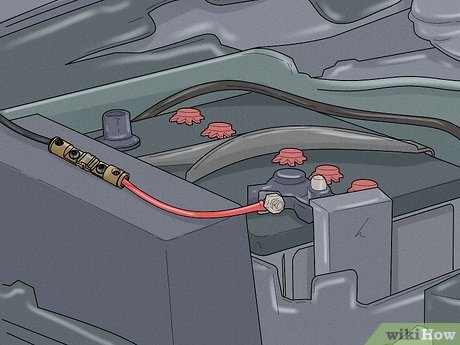

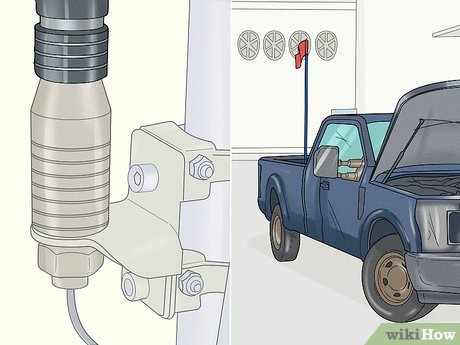

Attach an inline fuse to the frame if space permits. Purchase an inline fuse holder, a 3-amp fuse, and zip ties. Find an open spot near the battery, secure the fuse with zip ties, and insert the 3-amp fuse into the holder.

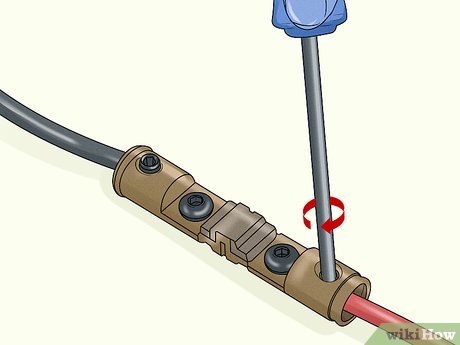

Insert the red power wire into one end of the inline fuse holder. Push the wire from the power lights into the holder's terminal. Tighten the terminal screw to secure the wire in place.

Connecting Wiring to the Battery

Measure and cut a piece of red wire to fit between the fuse and battery. Use an 18-gauge red wire for this purpose. Determine the distance between the fuse and battery, cut the wire accordingly, and strip 1⁄2 in (1.3 cm) of insulation from both ends.

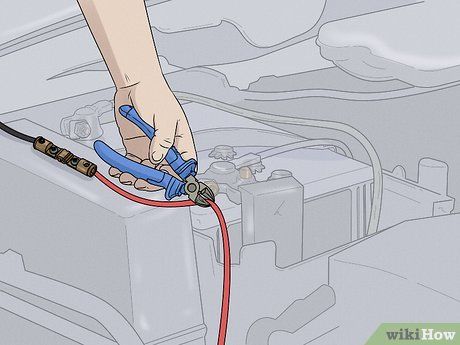

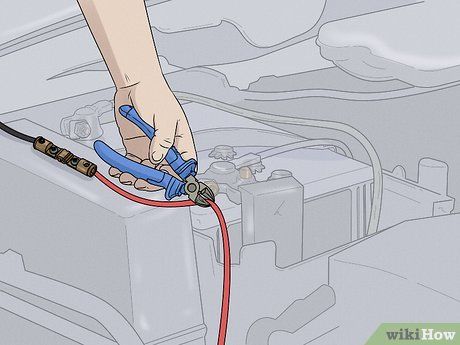

Attach a ring terminal to one end of the red wire. Ring terminals are simple connectors that fit onto battery terminals. Insert the exposed wire into the terminal and use pliers to crimp down the insulation, securing it around the wire.

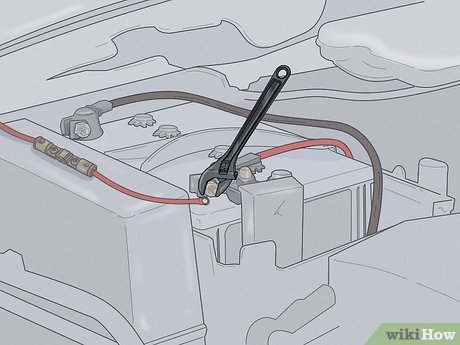

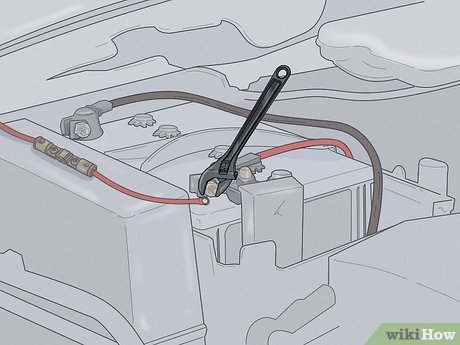

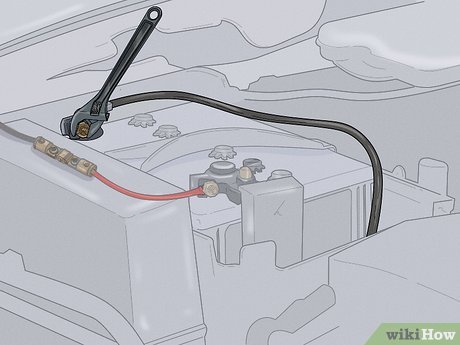

Loosen the nuts on the vehicle's battery cables using a wrench. Rotate the nuts clockwise to release them. Each terminal on the battery corresponds to a cable, typically black and red. Ensure the lighting wires are connected to the appropriate terminals.

Connect the red wire to the positive terminal of the battery. Slide the ring terminal onto the battery terminal and fasten the locking nut clockwise using a wrench. Confirm that the wire is properly attached to avoid blowing the fuse.

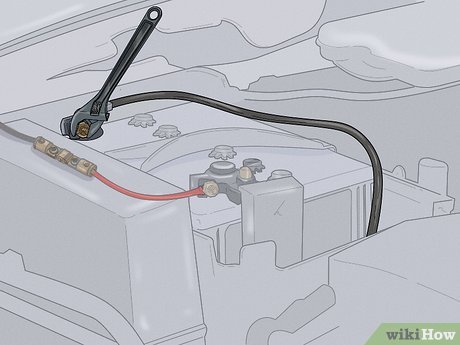

Attach the black wire to the negative terminal of the battery. Identify the black wire connected to the whip lights and strip 1⁄2 in (1.3 cm) of insulation from the end if necessary. Then, affix a ring terminal to it and place it onto the battery terminal before tightening the locking nut.

Wrap the wire connections with electrical tape for added protection. Although durable, covering them reduces the risk of wire fraying. Begin with the connector under the whip light and secure any other connectors as well.

Secure the wiring to the vehicle's frame using zip ties. Identify loose wiring sections and wrap zip ties around them and the frame. Combine and bind the black and red wires together securely against the frame.

Fasten the whip light into its base at the rear of your vehicle. Insert the tube into the previously mounted base and rotate it clockwise until it locks in place. Ensure the whip light is firmly secured to your vehicle, checking the stability of the mounts and the light itself on the frame.

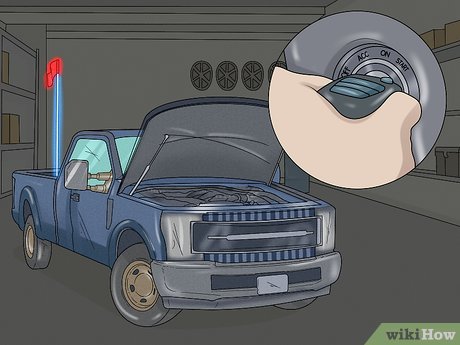

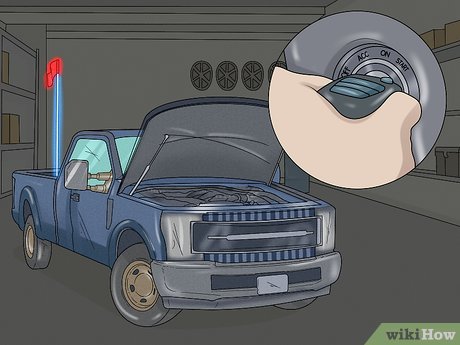

Test the lights by turning on the vehicle. Before reassembling any removed parts, conduct a test run of the lights. Power up your vehicle and activate the lights using the control switch. If everything functions correctly, the lights will illuminate, enhancing your ride.

Reinstall the hood, dashboard, and any other removed components. Begin by reattaching panels inside the vehicle, starting with the dashboard and central console. Secure the seats and then replace the hood. After completion, showcase your vehicle's new glow by taking it for a ride!

Useful Tips

-

If unsure about installing whip lights on your specific vehicle, consult the lighting manufacturer for guidance. Although installation procedures may vary, customer support can offer assistance based on your vehicle type and the product you're using.

-

Whip lights are available in various lengths and colors, with many offering color-changing capabilities and wireless remotes for control post-installation.

-

Whip lights can typically integrate with existing wiring systems, allowing you to splice old and new wiring together for seamless operation.

Whip lights come in diverse lengths and colors, often with color-changing features. Utilize the remote control, if available, to select your desired color.

Important Warnings

Exercise caution when handling electrical components to prevent electric shock. Always switch off your vehicle before working with the battery or any wiring.

Ensure proper connection of all wiring in accordance with the manufacturer's instructions. Incorrect wiring arrangements may lead to burnout.