Created in 1934 by O.G. Schmidt, electric trolling motors enable anglers to control their boats at slower speeds than trolling speed with an outboard motor, offering superior control compared to a paddle or oars. They also provide an alternative for propelling boats across lakes where 'no-wake' regulations apply or in most lakes where gasoline-powered outboard motors are prohibited. Trolling motors cater to both freshwater and saltwater fishing and can be installed in one of three locations: on the transom (stern), on the engine itself, or on the bow. The following are guidelines on how to mount a trolling motor in each of these positions.

Procedures

Mounting a Trolling Motor on the Transom

Release the clamps on the mounting bracket. Transom-mounted trolling motors come with 1 or 2 clamps integrated into the mounting bracket to secure the motor in place. Rotating the clamps counterclockwise (to the left) will unlock them.

Position the motor onto the transom. Place the trolling motor near the center of the stern, ensuring it doesn't interfere with the main motor's operation, if present. Align the top of the mounting bracket with the stern's top edge.

Secure the clamps tightly. Rotate the clamps clockwise until fully tightened to prevent the motor from loosening during operation.

- Ensure that the center of the motor section of transom-mounted trolling motors is submerged at least 9 inches (22.5 cm) while running to avoid noise that can startle fish.

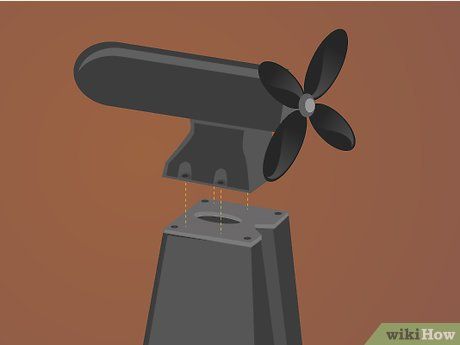

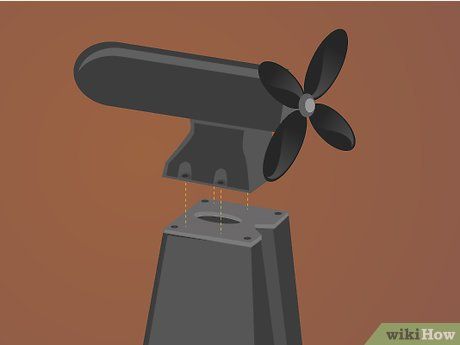

Installing a Trolling Motor on the Engine

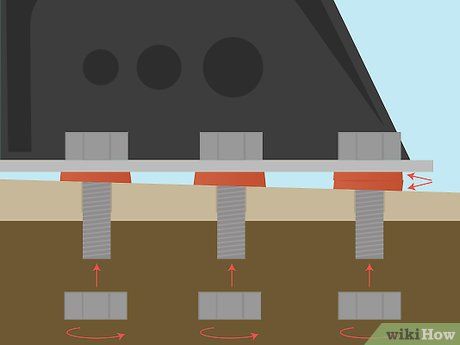

Position the mounting bracket atop the engine's anti-cavitation plate, with the motor raised. The anti-cavitation plate, located above the propeller on outboard motors or the outboard unit of inboard-outboard motors, prevents the propeller from breaking the water's surface during forward propulsion. The mounting bracket ensures that the trolling motor breaks the water's surface when the boat is 'on plane,' with the bow lifted above the water.

- Ensure that the anti-cavitation plate extends at least 13 inches (32.5 cm) below the waterline, allowing the trolling motor to operate at least 6 inches (15 cm) below the waterline.

Mark the drill holes on the anti-cavitation plate using the mount as a guide.

Drill holes for the mounting bolts. Utilize a drill bit capable of piercing through the metal of the anti-cavitation plate.

Position the mounting bracket on the anti-cavitation plate once more.

Insert and tighten the mounting bolts. This action will firmly secure the trolling motor.

- Engine-mounted trolling motors are specifically intended for V-hull or tri-hull boats that achieve a planing position. They are not suitable for use with pontoon boats or sailboats.

Mounting a Trolling Motor on the Bow

Detach the trolling motor assembly from the mount base. Bow-mounted electric trolling motors are engineered for use on boats featuring flat, elevated forward decks. Such decks are commonly found on bass boats, designed for precise boat control while fishing in shallow waters with vegetation and obstacles.

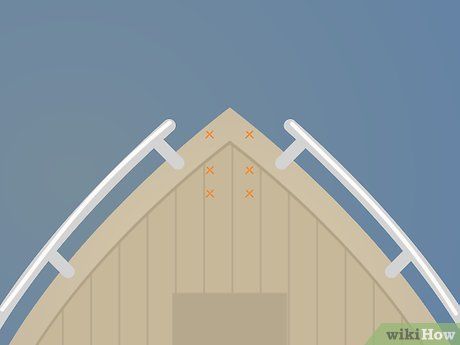

Select the spot on the deck where the base should be affixed. Ensure it accommodates the motor both during operation and when stored on deck while the main motor propels the boat. The location should allow enough clearance for the motor to detach from the base if equipped with a breakaway mount, and the mounting screws should penetrate the deck without reaching the hull.

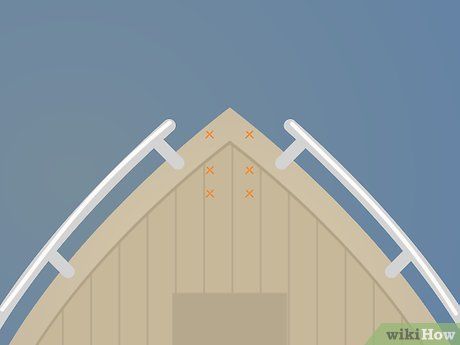

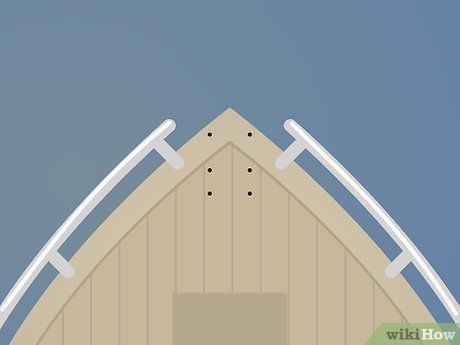

Mark the drill holes on the deck. Use the mount base as a guide for this step.

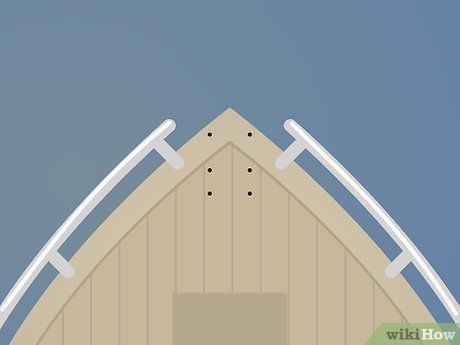

Drill holes for the mounting bolts. Use a sharp drill bit and drill to a depth of 1/4 inch (6.5 mm), ensuring to clear any debris afterward. If the boat is fiberglass, countersink the holes.

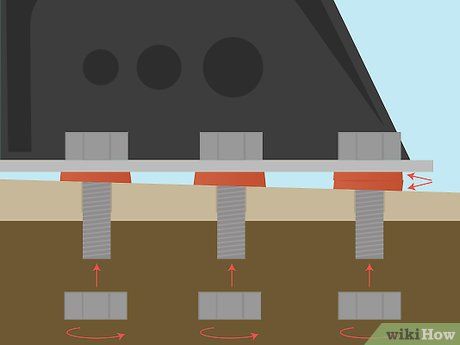

Insert a bolt through each hole in the mount base.

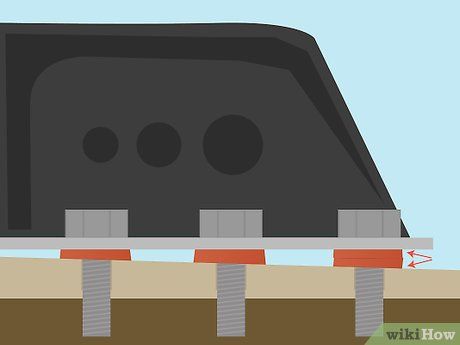

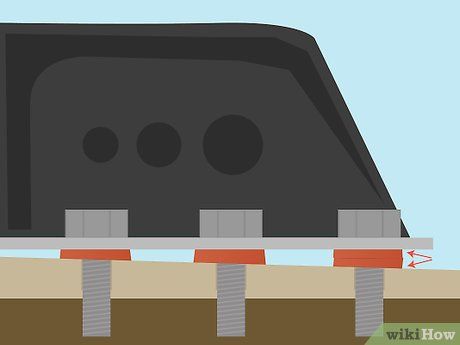

Slide a rubber washer onto each bolt, beneath the mount base. Hold the washers in place with your fingers as you position the mount base over the drilled holes in the deck. If this proves difficult, place the washers over the drilled holes first.

Position the base over the drilled holes, passing the bolts through each hole.

Ensure the base sits level against the deck surface. If it's uneven, add additional rubber washers under the bolts to stabilize it.

Attach a steel washer and retaining nut onto each bolt. Tighten the nuts to firmly secure the base in place.

Fasten the motor assembly to the base.

InsightsMany trolling motors are adjustable vertically to ensure proper operating depth for the propeller.

An electric trolling motor meant for transom mounting can also be adapted for bow mounting on a V-hull boat or for backtrolling by adjusting the control unit.

Consider using a tie-down strap to secure the bow-mounted electric trolling motor in rough water conditions.

- Drill (for bow or engine mounted trolling motors)

- Drill bits (for bow or engine mounted trolling motors)

- Bolts or screws (usually included in mounting kit)

- Retaining nuts (usually included in mounting kit)

- Metal washers (usually included in mounting kit)

- Rubber washers (for bow or engine mounted trolling motors)

- Wrench or screwdriver (for bow or engine mounted trolling motors)