Acknowledging that Intel is also in possession and operation of semiconductor manufacturing machines based on the Extreme Ultra Violet (EUV) lithography technology produced and supplied by ASML in the Netherlands. However, in the image below is a segment of the High NA EUV lithography machine named Twinscan EXE:5000, a modern, powerful, and the most expensive product created by ASML, and the first of its kind globally. Intel is the pioneer unit to own this machine.

Acknowledging that Intel is also in possession and operation of semiconductor manufacturing machines based on the Extreme Ultra Violet (EUV) lithography technology produced and supplied by ASML in the Netherlands. However, in the image below is a segment of the High NA EUV lithography machine named Twinscan EXE:5000, a modern, powerful, and the most expensive product created by ASML, and the first of its kind globally. Intel is the pioneer unit to own this machine. Twinscan EXE:5000 is a colossal machine in the truest sense, requiring 13 truck containers, and 250 new cargo boxes for transportation. After complete assembly, this machine stands as tall as a 3-story building. Due to its size, Intel had to expand their fab in Hillsboro, Oregon, just to accommodate this machine. The estimated cost for a Twinscan EXE:5000 ranges from 300 to 400 million USD.High NA EUV machines, equipped with large numerical apertures ranging from 0.33 to 0.55, will enable the processing of chips with transistor density equivalent to 1nm processes. Current EUV machines can only cater to semiconductor chip production up to a maximum of 2 or 3nm processes. Hence, some believe that High NA EUV scanners will be the key tool for humans to continue advancing the semiconductor industry according to Moore's Law, in the period from 2025 to 2026, as Intel, Samsung, and TSMC begin commercializing 2 or 1nm processes.Estimatedly, High NA EUV lithography technology will allow the semiconductor manufacturing industry to progress for another 10 years before requiring newer technologies.

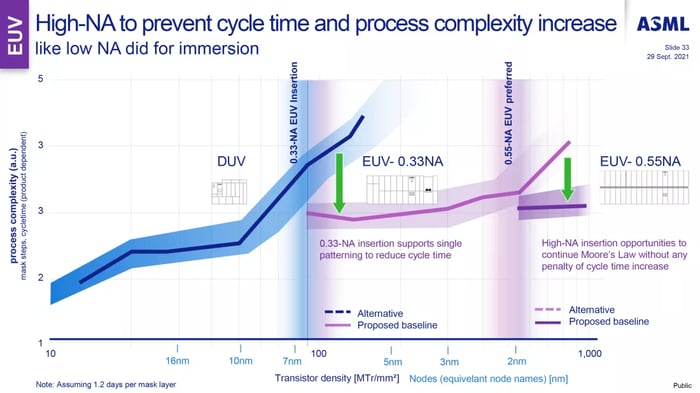

Twinscan EXE:5000 is a colossal machine in the truest sense, requiring 13 truck containers, and 250 new cargo boxes for transportation. After complete assembly, this machine stands as tall as a 3-story building. Due to its size, Intel had to expand their fab in Hillsboro, Oregon, just to accommodate this machine. The estimated cost for a Twinscan EXE:5000 ranges from 300 to 400 million USD.High NA EUV machines, equipped with large numerical apertures ranging from 0.33 to 0.55, will enable the processing of chips with transistor density equivalent to 1nm processes. Current EUV machines can only cater to semiconductor chip production up to a maximum of 2 or 3nm processes. Hence, some believe that High NA EUV scanners will be the key tool for humans to continue advancing the semiconductor industry according to Moore's Law, in the period from 2025 to 2026, as Intel, Samsung, and TSMC begin commercializing 2 or 1nm processes.Estimatedly, High NA EUV lithography technology will allow the semiconductor manufacturing industry to progress for another 10 years before requiring newer technologies. Thanks to realizing a mistake over a decade ago and placing early orders for the Twinscan EXE:5000 machine, Intel will test the capabilities of this machine ahead of both TSMC and Samsung. The two Asian entities will have to wait several more years to receive the lithography machines they ordered from ASML.A noticeable distinction lies in both the Twinscan EXE:5000 test machine and the machine used in commercial semiconductor chip production, the Twinscan EXE:5200. Both require significant changes in semiconductor chip design and processing, encompassing processes, materials, mask coating layers for lithography on silicon wafer surfaces, and even semiconductor die verification tools. Having these machines beforehand means Intel will have an advantage in process testing, thereby refining the process earlier and more efficiently.In 2022, ASML set a goal to produce a complete 20 High NA EUV scan machines each year by 2027 and 2028. Currently, the Dutch conglomerate itself is running orders for dozens of machines to serve fabs and semiconductor manufacturing conglomerates worldwide.According to Techspot

Thanks to realizing a mistake over a decade ago and placing early orders for the Twinscan EXE:5000 machine, Intel will test the capabilities of this machine ahead of both TSMC and Samsung. The two Asian entities will have to wait several more years to receive the lithography machines they ordered from ASML.A noticeable distinction lies in both the Twinscan EXE:5000 test machine and the machine used in commercial semiconductor chip production, the Twinscan EXE:5200. Both require significant changes in semiconductor chip design and processing, encompassing processes, materials, mask coating layers for lithography on silicon wafer surfaces, and even semiconductor die verification tools. Having these machines beforehand means Intel will have an advantage in process testing, thereby refining the process earlier and more efficiently.In 2022, ASML set a goal to produce a complete 20 High NA EUV scan machines each year by 2027 and 2028. Currently, the Dutch conglomerate itself is running orders for dozens of machines to serve fabs and semiconductor manufacturing conglomerates worldwide.According to Techspot