Air conditioner copper pipes are vital components in the equipment's structure. This part plays many critical roles in gas circulation, boasting numerous advantages in terms of durability, thermal conductivity, and installation time. Let's delve deeper into copper pipes with Mytour to understand their operation, efficient installation, thus avoiding unnecessary risks.

> Explore More:

What Are Air Conditioner Copper Pipes?

Air conditioner copper pipes or gas conduits are among the most crucial components in refrigeration equipment installation. This part primarily functions to conduct gas flow from the unit to the condenser and vice versa.

Currently, copper pipes are available in a wide variety on the market, with diverse sizes, types, and coming from various large and small brands. Some are manufactured directly in Vietnam, while many are imported from abroad, such as Thailand, Hailiang, Malaysia, etc. Each type of air conditioner copper pipes possesses different advantages, disadvantages, and price ranges.

If you're in need of an air conditioner for scorching summer days, head over to Mytour for a diverse range of air conditioner models, including standing air conditioners, mini air conditioners, 9000 BTU air conditioners, 18000 BTU air conditioners, and more.

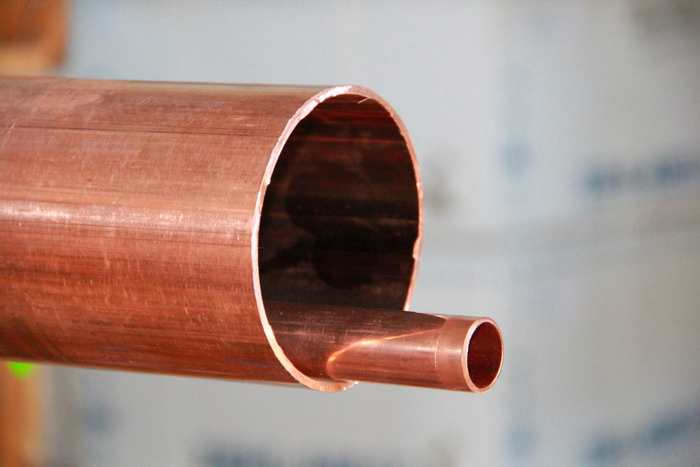

Copper pipes are an essential component of air conditioners (Source: Internet)

Copper pipes are an essential component of air conditioners (Source: Internet)The Function of Air Conditioner Copper Pipes

As mentioned earlier, air conditioner copper pipes perform the function of conducting gas flow from the unit to the condenser and vice versa. In other words, this component directly affects the cooling operation and durability of the unit. However, the question arises: why not use other installation materials instead of requiring the use of copper pipes?

Regarding this issue, almost all refrigeration technicians are familiar with the components of the condenser and the evaporator, specifically as follows:

- The condenser comprises: the compressor, the heat dissipating condenser, and the heat dissipation fan.

- The evaporator comprises: the heat absorbing evaporator, the air flow guiding fan, the temperature sensor, the control system, and the condensate drain pipe.

As a result, the high-pressure compressor pushes the refrigerant in liquid form through the condenser coils, where it releases heat and is cooled by a fan. Upon exiting the condenser, the high-pressure liquid refrigerant is pushed through copper pipe A into the house.

Arriving at the indoor evaporator coil, the refrigerant must pass through an extremely narrow copper pipe, commonly referred to by HVAC technicians as a capillary tube. It is this capillary tube section that increases the pressure within the air conditioning system, leading to the refrigerant's liquefaction.

Air conditioner copper pipes directly impact the efficiency of the equipment (Source: Internet)

Air conditioner copper pipes directly impact the efficiency of the equipment (Source: Internet)At the end of the capillary tube, the refrigerant enters the evaporator coil, which consists of a system of large-diameter piping. The sudden pressure drop causes the liquid refrigerant to evaporate and absorb heat as it travels through the evaporator coil. Then, the refrigerant in vapor form travels back to the compressor through copper pipe B to repeat the cycle. This process continues continuously.

Among all the materials used for air conditioning installation, copper pipes account for up to 50% of the total value. Their primary task is to facilitate the flow of gas, which is why this material is always prioritized.

Copper pipes serve as crucial conduits for gas flow, ensuring the stable operation of air conditioners (Source: Internet)

Copper pipes serve as crucial conduits for gas flow, ensuring the stable operation of air conditioners (Source: Internet)> Check out the top-selling air conditioning products on Mytour:

Standards for installing copper pipes in air conditioners

Here are some important standards to consider when installing air conditioner copper pipes to ensure durability and efficiency:

Standard Sizes

Each manufacturer has detailed regulations on the size of copper pipes for air conditioner installation to ensure stable operation, energy efficiency, and durability. Incorrect installation or using copper pipes that are too long or too short according to the manufacturer's specifications can result in warranty rejection in case of malfunctions.

Currently, this component of air conditioners mainly utilizes two types of pipes: pipes from the condenser to the evaporator (suction line) and pipes from the evaporator to the condenser (liquid line). The diameter of the suction line is always smaller than that of the liquid line. Here are some specific standards for copper pipes that users need to consider for proper installation:

- 1 HP Air Conditioner (equivalent to 9000 BTU): The suction line has an outer diameter of 6mm and the liquid line has a diameter of 10mm.

- 1.5 HP Air Conditioner (equivalent to 12000 BTU): The suction line has an outer diameter of 6mm, and the liquid line has a diameter of 10mm or 12mm.

- 2 HP Air Conditioner (equivalent to 18000 BTU): The suction line has an outer diameter of 6mm, and the liquid line has a diameter of 12mm.

- 2.5 HP Air Conditioner (equivalent to 24000 BTU): Both the suction line and the liquid line have outer diameters of 6mm and 16mm, respectively.

Additionally, users can find more information about the recommended sizes of copper pipes in the technical specifications section on the product page.

The standard sizes of air conditioner copper pipes are designed according to the manufacturer's specifications (Source: Internet)

The standard sizes of air conditioner copper pipes are designed according to the manufacturer's specifications (Source: Internet)Distance between the condenser and the evaporator

Similar to dimensions, the length of the copper pipe connecting the condenser and the evaporator must also comply with the installation requirements set by the manufacturer. The reasons are as follows:

- Short copper pipes: Short copper pipes may cause the refrigerant/gas to not return to the compressor in time, leading to blockages and severe damage.

- Long copper pipes: Excessively long copper pipes can slow down or impede the cooling process of the air conditioner. Moreover, if the size of the pipes exceeds the manufacturer's specified limits, warranty claims may be rejected.

Thus, each manufacturer and model of air conditioner has different lengths for installing copper pipes. Typically, the minimum length is around 3m and the maximum is about 15m to 20m for high-capacity units. However, the optimal operating length generally falls between 3m and 7m. Users can find specific information about the recommended distances for each unit in the technical specifications section of each product.

Difference in height between the condenser and the evaporator

In addition to the length of the copper pipes connecting the two units, users should also pay attention to the height difference between the condenser and the evaporator. This figure must fall within the manufacturer's specified limits and depends on the length of the pipes.

In reality, the height difference between the condenser and evaporator doesn't have much impact. This is because most users typically install both units on the same floor inside the house. However, this specification becomes crucial for high-rise buildings, apartments, and skyscrapers. Users can find more detailed information in the product's technical specifications section.

> Buy Panasonic 1hp air conditioner now, Inverter technology for energy savings, great price at Mytour

Important criteria to note during the installation of air conditioner copper pipes (Source: Internet)

Important criteria to note during the installation of air conditioner copper pipes (Source: Internet)Common Sizes of Copper Pipes for Air Conditioners Nowadays

Below is a table of copper pipe sizes for some popular air conditioner models on the market today. Users can refer to this to make informed installation decisions:

| Dòng máy | Máy lạnh Inverter | Máy lạnh non-Inverter |

| Máy lạnh Toshiba | Model N3KCV:1 HP dùng ống 6/101.5HP dùng ống 6/102 HP dùng ống 6/12.7 | Model N3KPX:1 HP dùng ống 6/101.5HP dùng ống 6/12.72 HP dùng ống 6/12.7 |

| Máy lạnh Daikin | Model FTKS:1 HP dùng ống 6/101.5HP dùng ống 6/102 HP dùng ống 6/12.7Inverter Gas R22: FTKDFTKD25 6/10FTKD35 6/12FTKD50 6/12 | Model FTE:1 HP dùng ống 6/101.5HP dùng ống 6/12.72 HP dùng ống 6/16 |

| Máy lạnh Panasonic | Model TS:1 HP dùng ống 6/101.5HP dùng ống 6/12.72 HP dùng ống 6/12.7 (dành cho mã M-N-P). Date 2014 mã Q dùng ống 6/16 | Model KC / C:1 HP dùng ống 6/101.5HP dùng ống 6/12.72 HP dùng ống 6/12.7. Riêng model 2 HP date 2014 mã đuôi QKH dùng ống 6/16 |

| Máy lạnh Sharp | 1 HP dùng ống 6/101.5HP dùng ống 6/12 | 1 HP dùng ống 6/101.5HP dùng ống 6/122 HP sử dụng ống 6/12 |

| Máy lạnh Fujitsu/General | 1 HP dùng ống 6/101.5HP dùng ống 6/102 HP dùng ống 6/12.7 | 1 HP dùng ống 6/101.5HP dùng ống 6/12.72 HP dùng ống 6/12.7 |

Air conditioner copper pipes come in various sizes compatible with different types of equipment (Source: Internet)

Air conditioner copper pipes come in various sizes compatible with different types of equipment (Source: Internet)Common Questions When Using Air Conditioner Copper Pipes

During the use of air conditioner copper pipes, users inevitably encounter certain concerns. Here are specific answers to common questions to give you a better overview:

How much does air conditioner copper piping cost?

The purchase price of an air conditioner does not include installation costs and copper piping. Each device with different capacities will use copper pipes of specific sizes. Consequently, the price levels will vary as follows:

- Price of copper piping with a capacity of 9000 BTU using 6/10 piping: 150,000 VND/m.

- Price of air conditioner copper piping with a capacity of 12000 BTU using 6/12 piping: 170,000 VND/m.

- Price of copper piping with a capacity of 18000 BTU using 6/16 piping: 200,000 VND/m.

- Price of copper piping with a capacity of 24000 BTU using 10/16 piping: 230,000 VND/m.

Additional material fees during installation may vary depending on the air conditioner model. Users should check for updates on the product page and purchase according to their needs.

However, it's worth noting that repairing or replacing copper pipes hidden in walls often incurs significant costs. To minimize unnecessary damage and prolong the lifespan of the component, users should consider the following important issues:

- When concealing copper pipes in walls, it's advisable to use high-quality, genuine materials and accessories and hire a reputable installation team to ensure the air conditioner can operate reliably for several years without issues such as damage or gas leaks.

- Limit disassembly or relocation of air conditioners as up to about 40% of issues arise from random incidents and poor installation techniques, leading to rusting, water leaks, etc.

- In cases where users wish to reuse old pipes, they should choose copper pipes used for no more than 2 years, and thoroughly check the quality and type of gas used in the old pipes before making a decision.

- To ensure safety and quality, users should only use air conditioner copper pipes for about 2 years of use.

Where to buy air conditioner copper pipes?

Copper pipes are a crucial component in air conditioner structures. Hence, manufacturers always impose strict standards and quality requirements. To ensure durable, energy-efficient, and effective cooling operation, users should choose reputable suppliers with transparent origins. For installation, prioritize professional units with high technical skills to perform accurate welding and jointing operations. 90% of gas leaks originate from these positions.

Why is it necessary to install standard air conditioner copper pipes?

Users should always prioritize installing standard air conditioner copper pipes due to the following great benefits:

- Ensures stable air conditioner operation, achieving maximum cooling efficiency.

- Increases durability for copper pipe components and extends their service life.

- Minimizes the risk of cracked pipes, gas leaks, pipe contraction affecting gas flow, thereby avoiding many unforeseen serious issues.

- Standard copper pipe installation makes it easier for manufacturers to provide warranty coverage in case of poor performance or malfunctions.

Install standard air conditioner copper pipes to avoid unforeseen mishaps (Source: Internet)

Install standard air conditioner copper pipes to avoid unforeseen mishaps (Source: Internet)Here is a compilation of all useful information about air conditioner copper pipes. Hopefully, with these insights from Mytour Blog, you have gained valuable knowledge to make the most suitable choice for your equipment, ensuring stable, durable, and cost-effective operation. Additionally, if you are interested in purchasing the latest equipment models, don't forget to visit Mytour to explore a wide range of high-quality products at competitive prices!