The recommended approach by the manufacturer, as well as DIY alternatives

Power seats offer significant convenience for enhancing comfort in your vehicle—until they malfunction. When faced with such an issue, dealing with a power seat can become quite a challenge. If you find yourself grappling with a stuck seat, continue reading to discover the necessary information and guidance to tackle the problem. In many instances, you can manually maneuver the seat. So, go ahead and assert control over that seat!

Essential Insights

- To adjust the seat forward or backward, utilize the crank socket near the seat motor with the “winder tool” available in your vehicle’s toolkit. (Refer to your owner’s manual for guidance.)

- If a winding tool is unavailable, consider using a power drill with a flexible extender. Alternatively, if you possess wiring expertise, attempt connecting the seat motor to a battery pack.

- Repairing the power seat necessitates removing the entire seat and undertaking relatively complex electrical work—consider engaging a professional for this task.

Procedures

What Causes the Power Seat to Stop Moving?

Potential Motor or Wiring Issues If your vehicle's battery and electrical system are functioning properly, the problem may lie with a faulty motor, wiring, or both. Symptoms may include the seat being unresponsive to adjustment levers or the motor emitting weak or unusual sounds. While a long-term solution involves replacing the faulty components, using a winder tool (or power drill) as outlined in this article can serve as a temporary workaround.

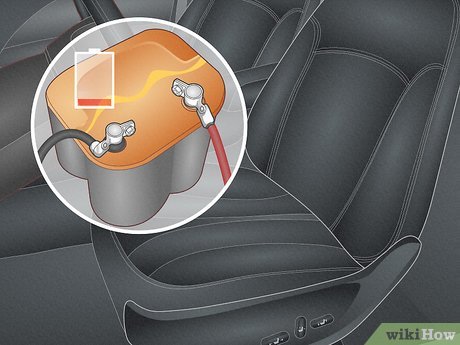

Power Supply Interruption In cases where the vehicle's battery is weak or depleted, the power seat will naturally fail to operate. This scenario commonly occurs when salvaging power seats from vehicles in junkyards. Employing a winder tool (or power drill) can provide a solution, or alternatively, connecting the seat's motor to an external battery (as discussed in this article) may be considered.

- If your vehicle's battery is weak or dead, Mytour offers assistance with jump-starting or replacing the battery.

Obstructed Mechanism Power seat mechanisms utilize long screw-like rods to adjust the seat along rails. If a part is bent, broken, or there's an obstruction, the mechanism may become jammed. Symptoms include minimal seat movement accompanied by loud or grinding noises from the motor. Unless the obstruction is accessible for removal, the recommended course of action involves seat removal and professional repair or replacement of the mechanism—an endeavor best left to skilled professionals.

Utilizing a Winder Tool

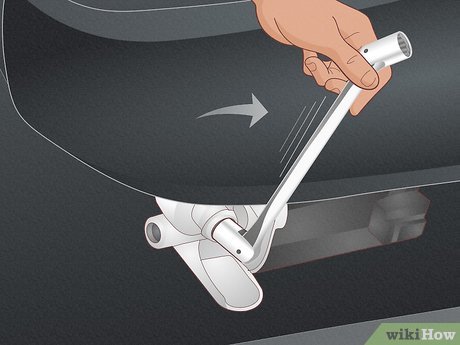

Check Your Vehicle's Toolkit for a Flexible Allen Wrench-Type Tool. Your vehicle likely includes a compact toolkit, which may contain a 'winder tool.' This tool resembles a blend of a flexible drill bit extender and an allen wrench, featuring a long, flexible shaft with a bit (usually square or hexagonal) at one end and a rigid, bent handle at the other.

- Your vehicle's toolkit is typically stored with other emergency repair items like the spare tire and jack. Refer to your owner's manual for precise details.

- If you don't have a winder tool, consider searching online, though they can be challenging to find. Additionally, note that winder tools aren't universally compatible and may not work with your specific power seat motor.

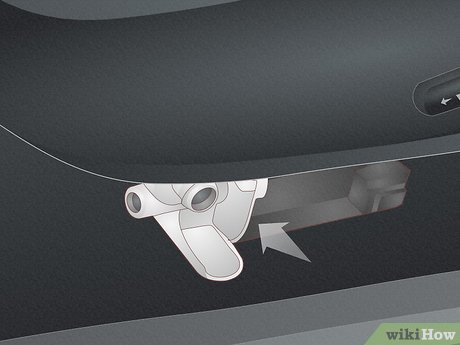

Locate the Motor Beneath the Seat and Identify the Socket. The motor's position varies by vehicle, but it's usually situated beneath the seat from the rear. Look for a small enclosed box, often along one of the seat's rails. On this motor box, find a socket opening matching the shape (typically square or hexagonal) of the winder tool's bit.

- It's possible that your power seat has multiple motors, each controlling different aspects of movement. Without guidance from the owner's manual, you'll need to locate and determine the function of each motor through trial and error.

- Be prepared with a flashlight, and don't be surprised if you encounter loose change or old food debris during your search!

Insert the Winder Tool's Bit into the Motor's Socket. If you have the correct winder tool provided with your vehicle, the bit should fit securely into the socket. In case you discover the wrong winder tool, consider using a power drill with a flexible extender bit—while not ideal, it may serve as your best alternative.

Rotate the Winder Tool's Handle to Adjust the Seat (Gradually). Typically, turning the handle clockwise will slowly move the seat backward, while counterclockwise turns will shift it forward. Confirm this by observing the movement—albeit slow, this method will eventually accomplish the task!

- If only one side of the seat moves, there may be two separate motors requiring manual adjustment. Search for a second motor opposite to the one you're addressing, and alternate between sockets to adjust the seat incrementally.

- It's likely that you'll only be able to adjust the seat forward or backward using the winder tool—not vertically, etc.

Can I Substitute a Drill for a Winder Tool?

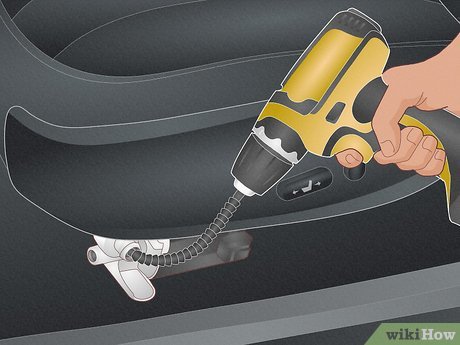

Consider Using a Power Drill if it Fits. While using a power drill may offer quicker results than a winder tool, it poses certain challenges. Finding a screwdriver bit suitable for the seat motor's socket may be difficult, as it's designed for the winder tool. Additionally, accessing the socket may require a flexible drill bit extender. If you manage to reach the socket and fit the bit, operate the power drill at its lowest speed for better control over the seat's movement.

- Running the drill at a slow pace reduces the risk of damaging the socket.

- If your seat has two motors controlling forward/back movement, alternate between them regularly with the drill to prevent misalignment and track jamming.

- Keep in mind that while this method might be as effective (or even faster) than using a winder tool, it's not endorsed in owner's manuals. The winder tool is specifically designed for this task, unlike a power drill.

Alternative Adjustments & Repairs

Apply Pressure on the Seat while Engaging the Adjustment Lever. This technique may work if the motor is partially functional but lacks the power to move the seat. By exerting pressure on the seat while activating the adjustment lever, you may provide the motor with the additional force it requires. However, be aware that this approach could potentially cause further damage to the power seat's motor and mechanism, leading to complete breakdown and necessitating alternative methods.

Apply Downward Pressure on the Seat while Pushing in the Desired Direction. Unlike assisting the motor's function by applying pressure, this method relies on sheer force to overcome a non-operational motor. By firmly pushing down on the seat while exerting force in the desired direction, you may achieve minimal movement along the tracks. However, there's a risk of causing damage to the seat mechanism.

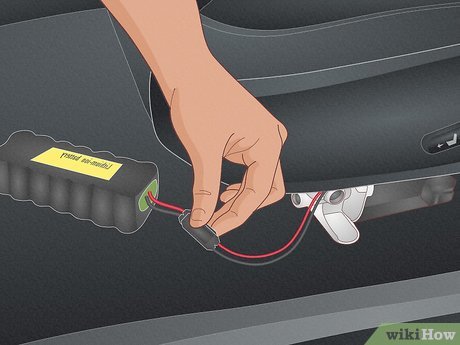

Connect the Motor to a Battery under Certain Conditions. Here's when this approach applies: 1) The seat motor operates but lacks power due to faulty wiring or a powerless vehicle; 2) You're willing to cut and strip the motor's wires; 3) You possess moderate to advanced electrical wiring skills. While this method is best suited for removing seats from junkyard vehicles, here's a breakdown of the process if you wish to attempt it:

- Locate the wire bundle leading to the seat motor, cut it, and strip the wire ends inside.

- Attach coated wire lengths to the two thickest wires within the bundle.

- Connect the wire ends to the positive and negative terminals of a battery, such as a battery pack with lead wires or a cordless tool battery. If the motor functions properly, the seat will initiate movement (switch terminals if the seat moves in the wrong direction).

Removing the Seat for Motor and Wiring Repair or Replacement. Repairing or replacing motors and wiring under a vehicle seat requires removing the seat due to space constraints. However, this process presents challenges for DIY enthusiasts:

- 1) Accessing the four bolts securing the seat requires moving it fully forward and backward—a difficult task when the power mechanism fails. Temporary solutions are necessary before attempting permanent fixes.

- 2) Modern power seats contain numerous wires and motors. Unless proficient in wiring, it's advisable to seek professional assistance from an auto garage.

- If the repair exceeds your capabilities, expect to pay approximately $800 USD for professional repair services.