To conceal the unsightly end grain of a board, there's no match for the finesse of a miter joint. Utilized for embellishing picture frames, door and window trimmings, as well as openings, miter joints, though delicate, serve as decorative elements, adding aesthetic appeal. While not ideal for heavy loads, they excel in enhancing visual appeal. Dive into Step 1 below to craft your own masterpiece.

Procedure

Preparation for Success

Equip Yourself with the Right Tools for Cutting and Measuring. Various tools cater to different mitering needs, depending on the material and type of cut required. For straightforward cuts on basic materials, a miter box and hand saw suffice. Complex cuts demand the precision of a circular or table saw, which can be rented from local hardware stores, with experts guiding you on the suitable machinery. In many instances of interior molding, such as baseboard and crown molding, mitering the inside corners is not recommended. It results in ill-fitting joints prone to separation. Instead, opt for the coping technique, easily learnable through online instructions.

Determine the Miter Angle. Calculate the total angle change and divide it by the number of pieces involved in the turn. This quotient represents the angle for setting your miter. Typically, a 45-degree miter angle prevails as the standard choice.

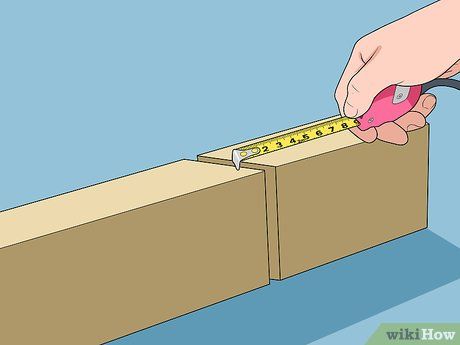

Mark the Starting Points. Due to angled cuts, one side of the wood will be longer than the other. Ensure accurate measurements, accounting for this length difference. For instance, on an inside corner piece, the wall measurement aligns with the longer back side of the wood. Conversely, for an outside corner piece, the inside measurement matches the wall but represents the shorter distance.

Determine the Angle Gap. Maximizing wood usage entails accounting for extra material, especially on longer sides necessitated by angled cuts like those on inside corners. For a standard 45-degree miter, calculate an end gap equal to the wood's depth. For non-45 angles, compute the sin and cos of the angle, then divide sin by cos and multiply the result by the wood's depth to determine the extra space required.

Cutting Procedure

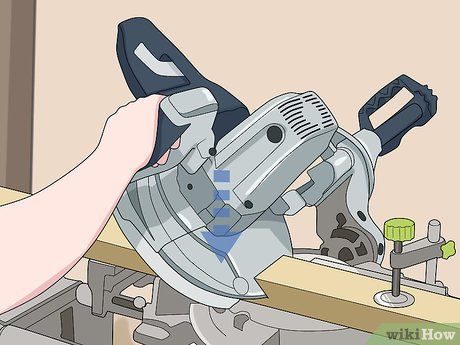

Align the Saw. Adjust the miter saw to the required cutting angle following the manufacturer's instructions provided with the machine, as setups may vary.

Position the Wood Correctly. Ensure the wood is placed on the machine with the appropriate orientation, preferably upside down. Always be mindful of the short and long sides of the wood. Utilize a laser guide if available, especially on newer machines. If uncertain, use scrap wood for testing cuts. Testing is crucial.

- For picture frame-style cuts, position the flat side on the cutting surface.

- For box-style cuts, align the flat side against the fence (or back piece of the cutting surface).

Secure the Wood with Clamps. If the wood is too short to hold securely or if your hands are at risk, use clamps to ensure stability. Exercise caution to prevent accidents, as mishandling can result in injuries.

Initiate and Lower the Saw. Follow the prescribed steps to start and lower the saw, as outlined in the machine's manual. When lowering the saw, apply gentle pressure and guide it without exerting excessive force. Allow the saw to perform the cutting task effortlessly.

Raise the Saw and Wait for Blade to Halt. Upon completion, raise the saw and wait for the blade to come to a complete stop before unclamping and removing your workpiece.

Assembling the Material

Utilize Clamps. Regardless of the joining method employed, securing the joint with clamps during setting is crucial. Various clamp styles are available to suit different projects. Seek guidance from your local hardware store to select the appropriate clamps for your needs.

Employ Glue and Nails. A fundamental approach involves gluing the angles, assembling them, and then securing them in place with pneumatic brad nails. This method is most effective when the pieces can be affixed to a base, such as a door frame, as the ends may not hold together well otherwise. If necessary, set the nails with a nail setter, fill the holes with wood putty, and finish by staining or painting the putty to match the wood.

Utilize Dowels. For thicker wood, drilling dowel holes and inserting dowels into the joined ends can provide additional support and enhance joint strength. Simply drill the hole, coat the dowel in wood glue, and join the pieces. Ensure the dowel size matches the wood thickness.

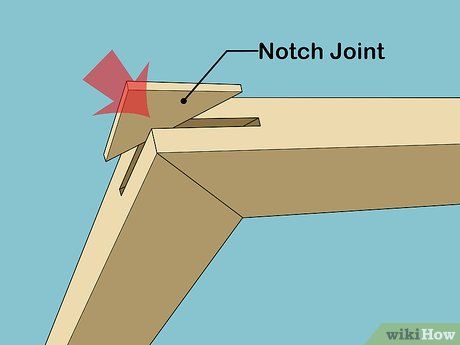

Explore Notch Joints. After joining the ends, consider employing a notch joint. Using a sturdy circular saw, create a notch in the joint corner. Fill the notch with glue and insert a triangular shim, cut to size and shape. While more advanced, this method can yield stunning results when executed properly.