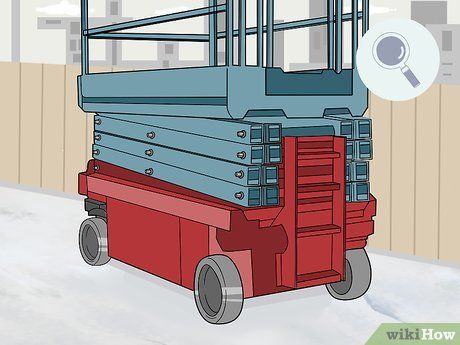

A scissor lift, a marvel of engineering prowess, serves as a versatile aid in numerous industries ranging from construction to cinematography. Its purpose extends to facilitating maintenance tasks, accessing high shelves in warehouses, or capturing captivating camera angles on film sets. To navigate this machine adeptly, toggle the horizontal switch to alternate between driving and elevating the platform. Adjust the lift's speed using the vertical switch and maneuver with precision using the joystick. Prioritize safety by donning a secure safety harness and waiting for the lift to come to a complete halt before making any adjustments. It's worth noting that different brands may vary slightly in controls and sensitivity, necessitating familiarization before operation.

Key Steps

Activating and Deactivating the Machine

- For gated entries, locate the locking mechanism at the frame's juncture and disengage it for access.

- Operating the scissor lift without securing the gate is strictly prohibited.

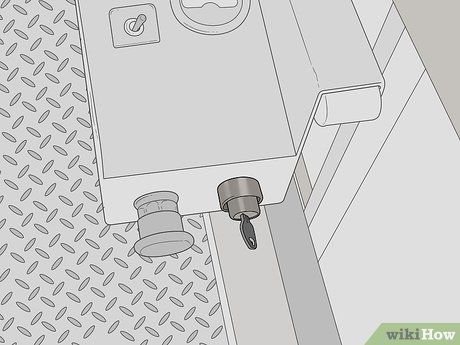

Pro Tip: Typically, operators and rental agencies leave the key in the ignition when the lift is not in use. If the key's whereabouts are unknown, start your search from the control panel.

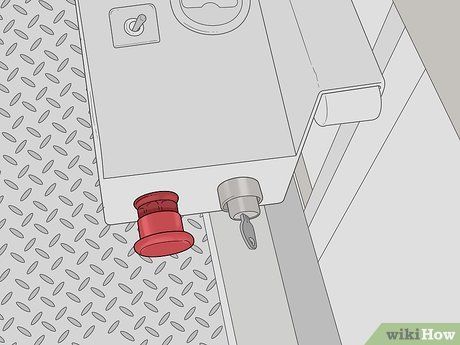

- To reactivate the lift post-emergency stop, pull out the button and utilize the key to restart the scissor lift.

Vertical Movement

Insider Tip: Reset the horizontal switch to its neutral position by shifting it to the middle. Activating the switch to the right powers the wheels. Always verify this switch before maneuvering the joystick.

- Maintain caution to prevent accidents or loss of control, especially during rapid movements.

- The fast setting is typically used in warehouses for accessing higher shelves where driving isn't required.

- Joysticks in scissor lifts are designed to return to the center position upon release, halting movement.

- During ascent, maintain vigilance to avoid collisions and ensure safety of surroundings.

- Ensure no individuals are in close proximity to the lift during elevation.

- Prior to descent, inspect the surroundings for safety, especially the folding rails which may pose a risk to nearby individuals.

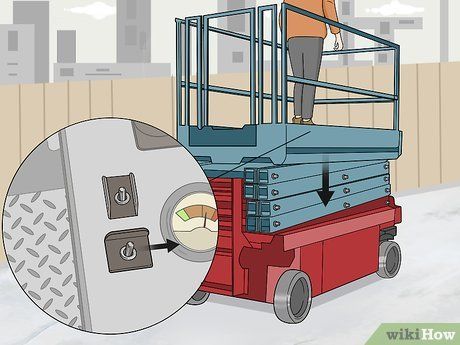

- Keep watch below during descent to prevent accidents, avoiding descent if anyone is within 20 feet of the lift.

Operating the Scissor Lift

- Moving a raised scissor lift may constitute a safety violation depending on local regulations.

- Platform adjustments are disabled in drive mode, so always lower the platform before activating this switch.

- “Fast” mode is typically used for navigating warehouse aisles where lateral movement isn't required.

Enhanced Joystick Functionality: Modern scissor lift joysticks are designed to respond to varying degrees of pressure when in drive mode. Gentle movements result in gradual motion, while full deflection maximizes speed according to your setting.

- Scissor lifts lack sharp turning capability, often necessitating multiple inputs for tight corners.

- While driving, maintain focus on the ground for obstacles or surface changes. Outdoors, periodically scan upward to avoid potential hazards like power lines or trees.

- Refrain from rapid back-and-forth joystick movements during direction changes to prevent instability or falling hazards. Quick movements may also result in collisions or platform disruptions.

Ensuring Safety Measures

- The nylon strap extends up to 6 feet before locking, providing ample maneuverability on the platform.

- Running out of energy while elevated requires assistance to recharge or refuel before descent. (Alternatively, consult the manual or manufacturer for the manual pressure relief valve, allowing descent regardless of energy status.)

- Most scissor lifts operate on electric power.

Important Reminder: Operating a scissor lift on uneven surfaces is often prohibited by law.

- If uncertain about the lift's safety, seek inspection by a certified mechanic before use.

- Scissor lift operator certifications typically require less than a week to complete.

- In some regions, mandatory training is enforced for scissor lift operation, although optional elsewhere.

- While requirements vary, scissor lifts are often categorized as scaffolding, which may not necessitate certification for use.

Useful Advice

-

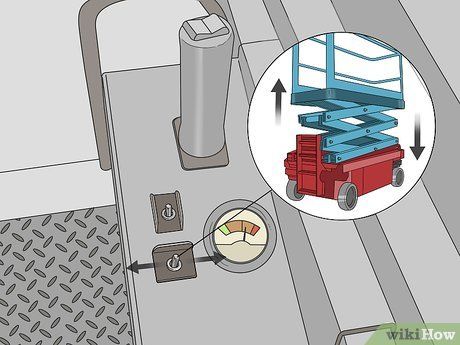

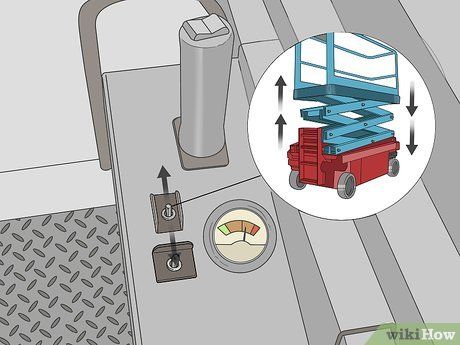

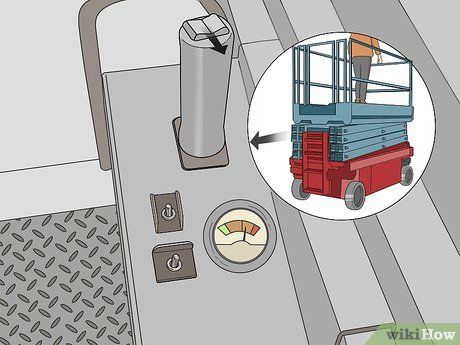

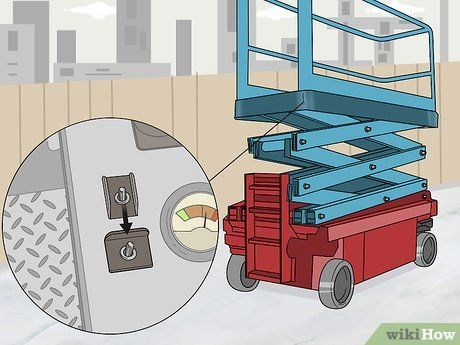

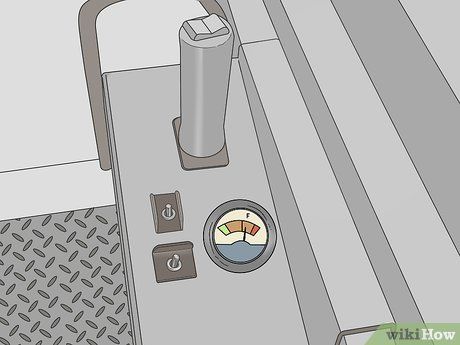

For tasks involving material handling or hydraulic testing, utilize the secondary control panel located at the lift's base. This panel is typically secured behind a cover on one of the longer sides of the machine.

-

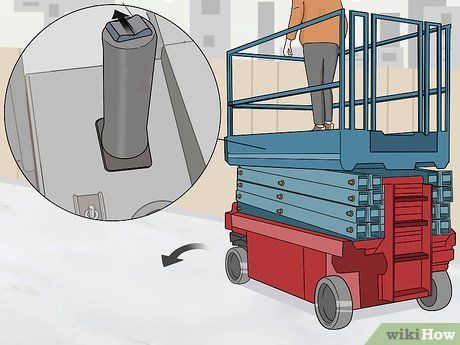

Many scissor lifts offer the option to extend the platform for increased maneuverability. Look for the pin locking mechanism securing the frame, and extend it horizontally at ground level. Keep in mind that extending the platform reduces the lift's weight capacity and increases susceptibility to sway when raised. Refer to the lift's safety sticker for weight limit information.

Cautionary Notes

- Avoid exerting excessive force while handling objects in elevated positions on a scissor lift, as even minimal force can cause tipping, especially at height.

- Annual inspection by a certified mechanic is imperative for scissor lift maintenance. When renting, request inspection records to ensure proper functioning before making any payments.

- Avoid operating a scissor lift in windy conditions, as even moderate winds can topple a raised lift. Exercise caution and refrain from raising the lift in windy conditions.

- Adhere to weight restrictions and avoid overloading the platform with heavy materials. Refer to online resources or the safety sticker on the control panel for weight limit information.

Essential Equipment

- Safety harness