Concerned about causing harm to nuts and bolts during tightening? Leave uncertainty behind with the torque wrench. It halts precisely upon reaching the designated torque, eliminating the peril of under or over-tightening during automotive or machinery maintenance. Setting up and utilizing your torque wrench is a breeze, and we'll guide you through every step. Dive in to discover how to calibrate your wrench and maintain it with finesse.

Essential Knowledge

- Loosen the locking knob at the end of the torque wrench.

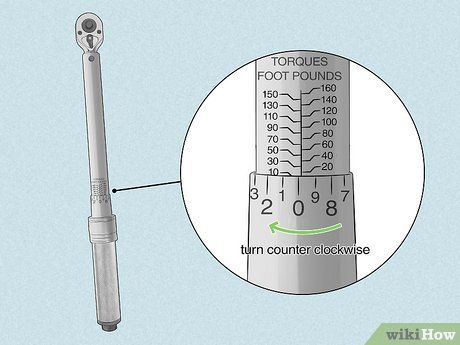

- Rotate the handle until its top edge aligns with the nearest torque value imprinted on the wrench.

- Adjust the top dial to match the desired number with the vertical line on the wrench. Combine the top dial number with the wrench for total torque.

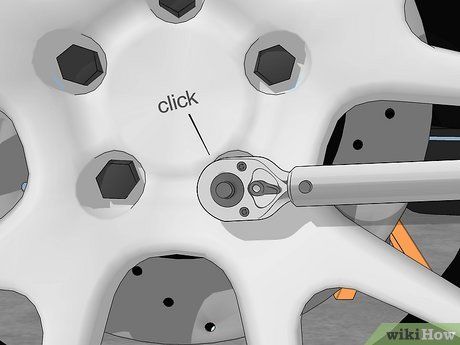

- Tighten nuts or bolts using your torque wrench until it clicks or stops moving.

Step-by-Step Process

Fine-Tuning the Wrench

- The locking knob often contrasts in color with the rest of the wrench for easy identification.

- No need to unscrew the knob completely; simply loosen it until the handle turns smoothly.

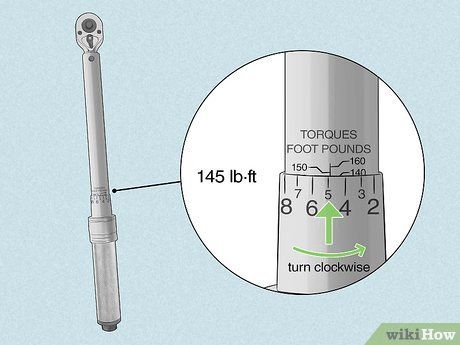

- Foot-pounds or meter-kilograms denote torque measurements indicating force applied over a specific distance. For instance, 1 lb·ft (0.14 kg·m) equals 1 pound (0.45 kg) of force over a 1 ft (0.30 m) distance.

- Most torque wrenches display both foot-pounds and meter-kilograms on opposite sides of the shaft. If both sets of numbers are on the same hash marks, the smaller number represents foot-pounds, while the larger indicates meter-kilograms.

- Example: If the desired torque is 145 lb·ft (20.0 kg·m), turn the handle until the top edge aligns with the hash mark for 140 lb·ft (19 kg·m).

- Some torque wrenches feature handles that slide rather than twist into position.

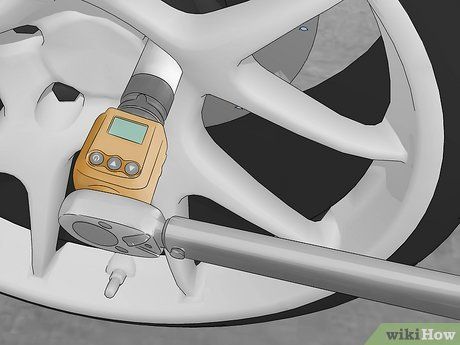

- If using a digital torque wrench, use the arrow buttons to adjust the torque setting. Each torque wrench operates differently, so consult your model's instructions for specifics.

Pro Tip: Consult your vehicle's manual to determine the appropriate torque for nuts or bolts. There are no universal torque setting rules for vehicles.

- Example: If aiming for a torque of 145 lb·ft (20.0 kg·m) with the handle already set to the 140 lb·ft (19 kg·m) mark, adjust the dial to 5 lb·ft (0.69 kg·m).

- Some wrenches feature a dial that moves independently of the handle, allowing direct twisting without engaging the handle.

- Example: With the handle at the 140 lb·ft (19 kg·m) mark and the dial at 5 lb·ft (0.69 kg·m), the total torque is 145 lb·ft (20.0 kg·m).

- Once the locking knob is secured, torque setting adjustments are inaccessible until you loosen it.

Fastening Nuts and Bolts

- If tightening in cramped spaces, attach a socket extender to your wrench beforehand.

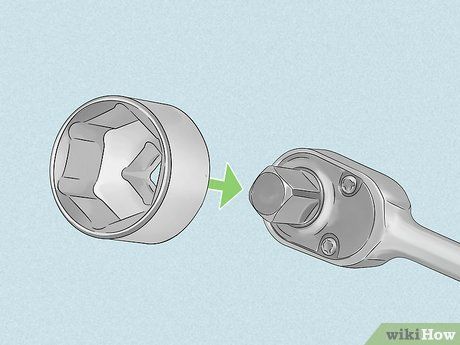

- Due to varying sizes, measure the square head on the end to select the correct socket size.

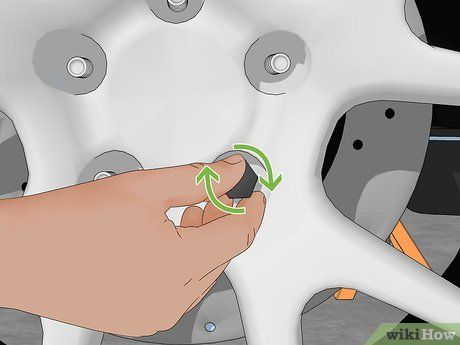

Caution: Refrain from using a torque wrench during initial nut or bolt attachment. Torque wrenches exert significant force, risking thread damage if alignment isn't perfect.

- If the socket spins freely without gripping the nut, opt for a smaller socket.

- If a clicking or switching sound occurs upon counterclockwise rotation, it indicates an automatic-return torque wrench.

- Remember, torque wrenches are designed for tightening only; counterclockwise rotation won't loosen fasteners.

- Avoid excessive force to prevent nut, bolt, or wrench damage.

Preserving Your Wrench

- Since torque wrenches should not be lubricated, apply a product like WD-40 degreaser to the nut or bolt before attaching the wrench's socket.

- Calibration typically costs $25-75 USD.

- Failure to calibrate may result in discrepancies between handle measurements and actual wrench torque.

Advice: Generally, aim for calibration once per year or every 5,000 clicks. Heavy daily usage, such as in automotive or biking repairs, may necessitate calibration every 8-10 months. For occasional DIY projects, calibration within the year is unlikely before reaching 5,000 clicks.

Mytour Video: How to Properly Use a Torque Wrench

Guidelines

-

A torque wrench is not designed for loosening nuts or bolts. For disassembly, opt for a socket wrench instead.

Precautions

- Impact or dropping can affect wrench calibration. When moving around the garage, carry it with both hands to prevent accidental drops.