You've crafted a miniature vehicle fueled by the snapping force of a mousetrap, aiming to propel it across the farthest distance possible. To outshine your peers, your goal is to refine your car's efficiency, ensuring it utilizes every ounce of potential. With strategic design and resourcefulness, you can optimize your car's performance for optimal distance, utilizing readily available household materials.

Steps

Enhancing Your Wheel System

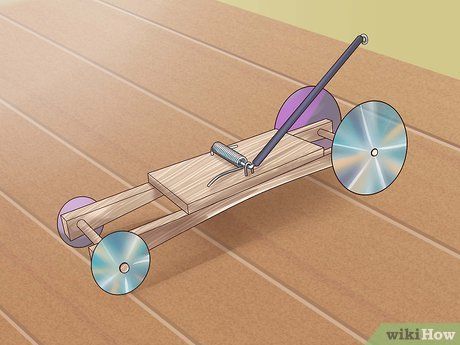

Utilize sizable rear wheels. Larger wheels possess greater rotational inertia compared to smaller counterparts. This attribute translates to enhanced momentum retention, enabling them to sustain movement for longer durations. Consequently, large wheels are ideal for distance-oriented competitions as they exhibit slower acceleration but prolonged rolling, resulting in increased overall travel distance. Therefore, for optimal distance achievement, prioritize installing large wheels on the drive axle (typically the rear axle).

- The front wheel's size is relatively less critical and can vary. However, for a traditional drag racing aesthetic, consider pairing large rear wheels with smaller front ones.

Opt for slim, lightweight wheels. Thinner wheels reduce friction, potentially maximizing the distance covered by your mousetrap vehicle. Consider the weight of the wheels as well — any excess weight will impede speed and increase friction. Wide wheels may even exacerbate air resistance, negatively impacting performance. Hence, prioritize using the thinnest, lightest wheels available, such as old CDs or DVDs, or thin vinyl if accessible. Plumbing washers can help adjust the hole size in CDs to fit the axle better.

Utilize a narrow rear axle. A slender rear axle allows for more turns per length of string, leading to increased wheel rotations and consequently greater distance traveled. Opt for narrow wooden dowel rods or thin metal rods, preferably lubricated to minimize friction, to construct your axle.

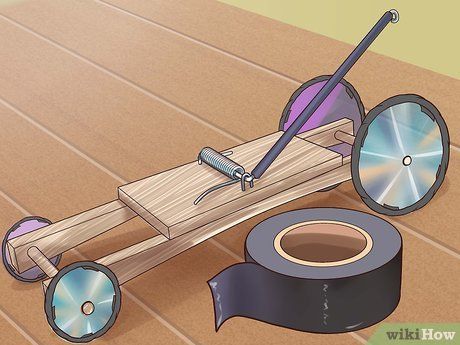

Enhance wheel traction to minimize slippage. Prevent energy wastage by reducing wheel slippage against the ground upon spring activation. Apply friction-inducing materials, such as electrical tape, rubber bands, or popped balloon rubber, sparingly to provide sufficient grip. Placing sandpaper under the rear wheels at the start line can further minimize slippage during initial movement.

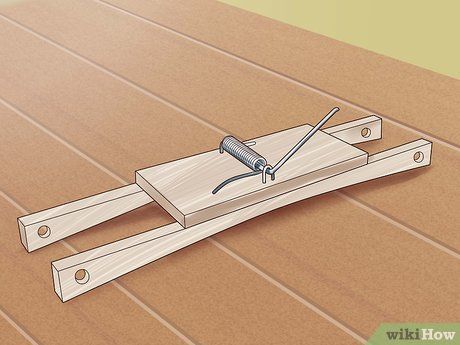

Customize Your Frame

Construct the lightest possible frame. Prioritize minimizing the car's mass, as lighter frames allow the mousetrap to exert greater force. Eliminate any unnecessary frame material and consider drilling holes to reduce weight where possible. Opt for lightweight materials like balsa wood, hard plastic sheets, thin metal sheets, or building toys like K'NEX or Legos for the frame construction.

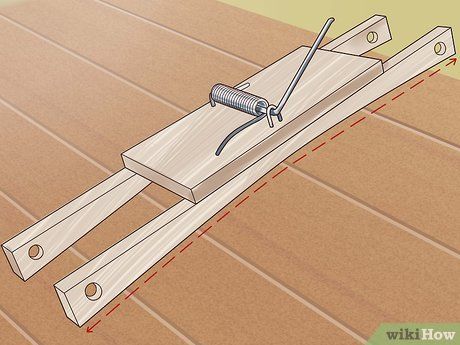

Opt for a sleek, elongated frame. Aim for an aerodynamic design to minimize air resistance and maximize efficiency. A long and narrow frame reduces drag, similar to the streamlined shapes of arrows, boats, airplanes, or spears. Ensure your frame is vertically slender and narrow to achieve the smallest possible profile. Examine your car from the front to identify any components that unnecessarily increase its size.

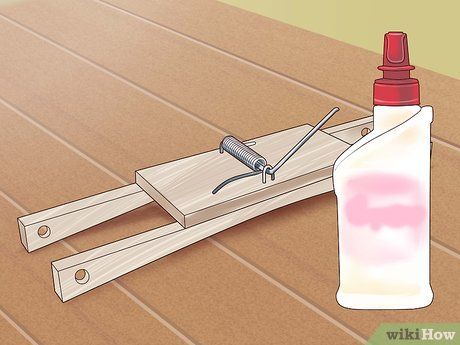

Use adhesive over nails when feasible. Prioritize glue over nails, pins, or other heavy attachments in your design. Apply small amounts of glue to secure the mousetrap to the frame, as it provides sufficient adhesion without adding excess weight. Opt for super glue for stronger bonds, avoiding school glue. Glue also minimally impacts air resistance compared to protruding nails, further enhancing performance.

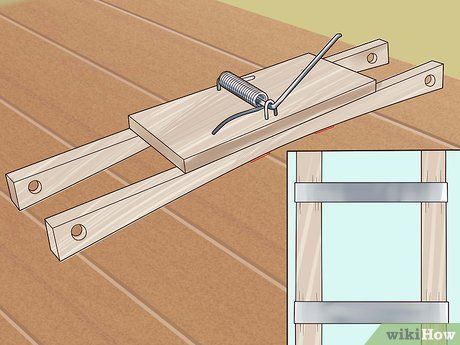

Maintain structural integrity while minimizing weight. Consider the balance between frame lightness and fragility, ensuring the car remains sturdy enough to withstand the mousetrap's force. Experiment with materials and reinforcements, such as adding metal or plastic strips underneath fragile frames, to enhance structural strength without significantly increasing weight or air resistance.

Boosting Power Efficiency

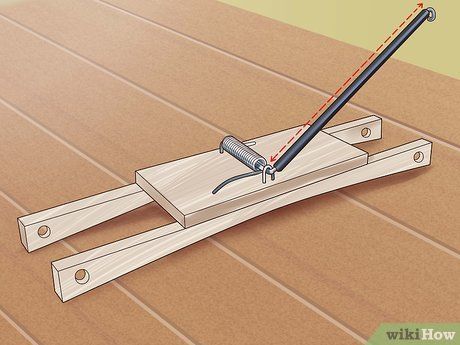

Extend the mousetrap's leverage with a longer arm. Enhance power transmission by attaching a longer lever to the mousetrap's arm, allowing for a slower, more controlled pull on the string. Use sturdy materials like reinforced balsa or metal to prevent bending and ensure efficient energy transfer from the mousetrap to the wheels.

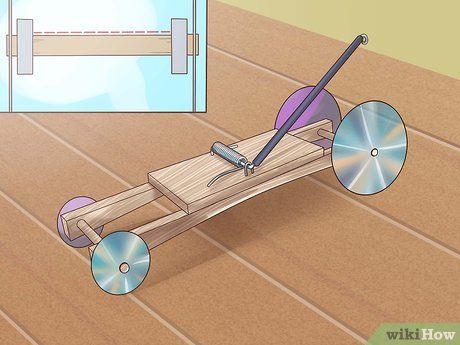

Place the trap as forward as possible. Optimize your mousetrap car's performance by positioning the trap as close to the front without interfering with the front wheels. Maximizing the distance between the trap and the wheels allows for more string to be wrapped around the axle, resulting in enhanced pulling power and smoother movement.

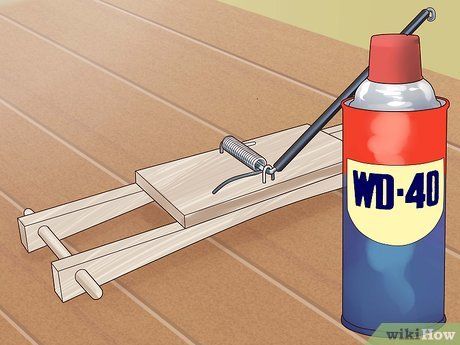

Reduce friction on moving parts. Enhance power efficiency by minimizing friction between the car's components. Apply a lubricant like WD-40 or auto grease to reduce friction points, especially on the axles, ensuring smooth operation and maximizing the utilization of the mousetrap's power.

Utilize the most powerful mousetrap available. If regulations permit, opt for the strongest mousetrap possible to maximize power output. Larger traps, such as rat traps, offer increased power but may require reinforcing the frame and axles to withstand the force. Exercise caution when handling large traps to prevent accidents.

Useful Tips

-

To improve distance, reverse the wheels and wind them backward for straighter movement. Enhance pulling power by using a larger drive hub and consider adding a rubber tire on the axle to reduce string slippage.

-

Extend the mousetrap arm with the longest available lever to increase wheel wraps and distance traveled. Opt for a lightweight, sturdy lever, such as an antenna from a broken boom-box.

-

Minimize axle friction by reducing the contact surface area between the axle support and the drive axle. Thin steel axle supports offer less friction compared to wood blocks with drilled holes.

Considerations

- Wheel-to-Axle Ratio: Optimize distance with large wheels and a small axle, resembling a bicycle's rear wheel setup.

- Inertia: Less mass means less energy required to start the car. Minimize vehicle mass for optimal distance.

- Rate of Energy Release: Slower energy release leads to more efficient power usage and longer travel distances. Lengthening the lever arm facilitates this, allowing more string wraps around the axle.

- Friction: Reduce axle friction by minimizing contact surface area, enhancing forward motion efficiency.

- Traction: Maximize traction where needed, such as where the string wraps around the axle and where the wheels touch the ground, to prevent energy wastage from slipping.

Precautions

- Be mindful of energy limits; exceeding them may hinder the car's movement. Adjust energy release by shortening the lever arm if necessary.

- Exercise caution when handling mousetraps to avoid injuries. Adult supervision is advised, especially when using tools or working with hazardous materials.