Bonding metal pieces together through gluing offers a straightforward solution for home improvement tasks and projects. But how can you ensure a reliable adhesion? Glue serves as an ideal option for smaller metal pieces that are not subjected to heavy wear and tear. Essential materials can be easily procured online or at your local hardware store. Below, we present a comprehensive guide to gluing metal to metal, encompassing suitable adhesives and preparation techniques for achieving a robust bond. If you're eager to delve into metal crafting, read on!

Key Considerations

- Opt for epoxy, polyurethane, or super glue. Consider factors such as adhesive strength, drying duration, and gap size between the metal pieces.

- Prior to applying adhesive, ensure thorough cleaning and light sanding of both metal surfaces. Subsequently, secure the pieces together with clamps for 1-2 hours to facilitate setting.

- Allow a 24-hour period for complete adhesive curing. Following this, your metal pieces will be securely bonded and ready for use.

Procedure

Choose the Right Adhesive for Your Metal

- Select epoxy for maximum resilience. It excels in strength, capable of filling gaps for imperfect fits. Available in flexible or rigid forms, it withstands heat and impact.

- Opt for polyurethane for household repairs of moderate intensity. Slightly less potent than epoxy, it offers ease of application. Ideal for outdoor projects due to its resistance to heat, UV rays, and water.

- Consider super glue for rapid bonding of small components. It excels in quickly adhering flat surfaces, without gap-filling capabilities. Perfect alignment of metal pieces is essential.

Safeguard Yourself from Adhesive Vapors

- Consider wearing a mask and goggles to shield against fumes and prevent adhesive contact with mouth, nose, and eyes.

- Lay down protective cloth or paper to safeguard your work surface.

- Gloves also prevent transfer of oils and greases from fingers to the metal surfaces.

Ensure Cleanliness of Both Metal Surfaces

- Keep gloves on to prevent leaving grease or fingerprints on freshly cleaned metal.

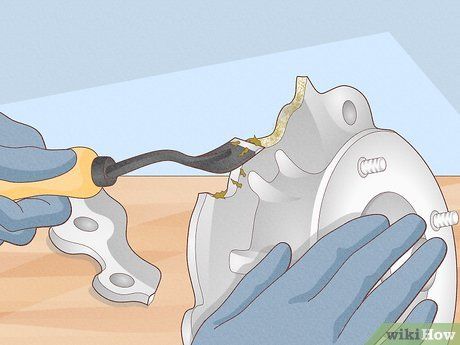

- Combat stubborn adhesives on metal with a potent solvent like acetone.

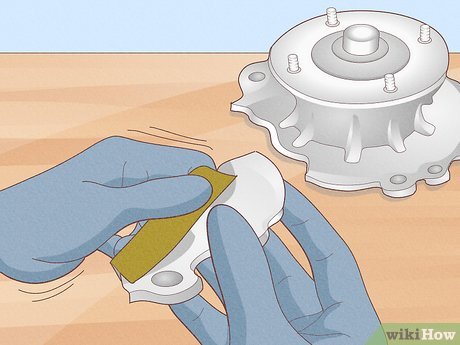

Utilize Fine-grit Sandpaper on Both Surfaces.

- After sanding, wipe metal with a clean rag or microfiber cloth to remove sanding dust or debris.

- Post-sanding, verify the fit of metal pieces. If fit is no longer snug, employ epoxy glue to bridge the gap.

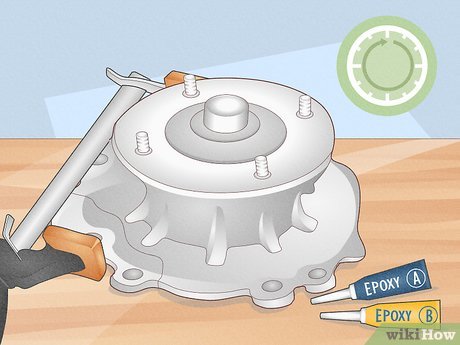

Apply Epoxy Resin to Both Surfaces.

- Prior to epoxy mixing, confirm metal cleanliness and sanding. Epoxy sets rapidly, so application should follow immediate mixing.

- Some epoxies feature a dual-chamber syringe for simultaneous hardener and adhesive mixing during application to metal.

Apply polyurethane glue onto one surface.

Apply super glue to one surface.

Secure the metal pieces with clamps.

- Place the bonded pieces in an undisturbed location during the setting period.

- To remove excess glue, use a rag dampened with acetone or mineral spirits.

Allow 24 hours for complete glue curing.

- When uncertain, opt for extended curing time.

- To remove dried glue from metal surfaces, utilize a razor blade.

- Upon completion of curing, the adhesive achieves maximum strength, rendering the metal ready for use or display.

Helpful Tips

-

Thoroughly review the glue manufacturer's instructions, as mixing and application procedures may vary by brand.

Cautionary Notes

- If adhesive comes into contact with your eyes, nose, or mouth, rinse with warm water for several minutes. Seek immediate medical attention and take the adhesive packaging to help identify its ingredients.