When replacing a drain valve on a sink or toilet, you may encounter a metal compression ring, commonly known as a ferrule, firmly attached to your pipe. Ferrules are essential for preventing pipe splitting, but their snug fit makes removal challenging. Fortunately, there are several methods you can employ. While most ferrules can be removed using pliers, stubborn ones may require specialized tools such as a compression ring puller or saw. Regardless of the method chosen, you'll have the old ferrule removed within minutes, ready to be replaced with a new one!

Steps

Accessing the Ferrule

Shut off the water supply. Before removing the valve from the pipe, ensure that the water supply is turned off to prevent any water from spraying out. Locate the main water supply valve, typically found in a basement, garage, or utility room, and turn it clockwise to shut off the water flow. Be sure to inform others in your home about the water shutdown to avoid inconvenience. Never attempt plumbing repairs with the water supply left on to prevent potential water damage.

Drain the water line in the area of operation. Activate the faucet or utilize the connected fixture to release any water from the pipe. Allow the water to flow until it ceases to come out from the faucet.

- If you're dealing with a toilet valve, continue flushing the toilet until the tank is empty.

Detach the angle stop from the pipe. The angle stop serves as the valve control situated beneath or near the fixture being worked on. Grasp the nut closest to the wall or floor using a pair of pliers. Stabilize the front of the angle stop to prevent it from turning. Rotate the nut clockwise to loosen it from the angle stop. Once loosened, manually unscrew the nut until it separates from the angle stop, revealing the ferrule encasing the pipe.

- If holding the front of the angle stop proves challenging, use another pair of pliers to secure it in place.

- There may still be residual water in the pipe. Place a towel or bowl beneath the valve to minimize spillage.

Removing a Ferrule with Pliers

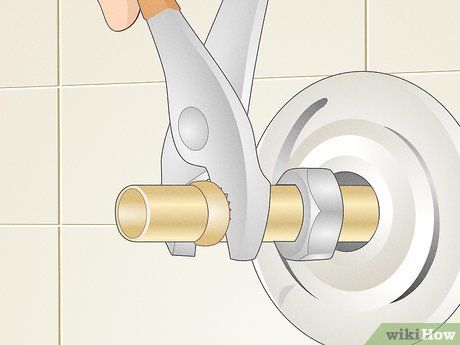

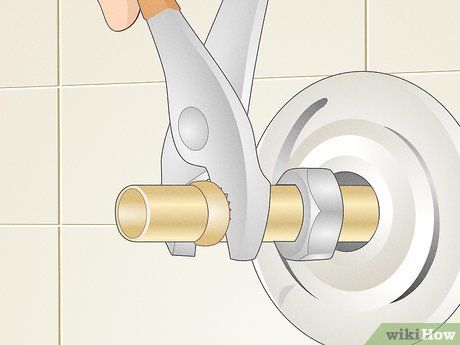

Attempt to rotate the ferrule using pliers initially to dislodge it. Adjust the pliers' jaws to fit around the ferrule on the pipe. Securely grip the ferrule by tightening the pliers. With your non-dominant hand, hold the pipe for added stability. Move the pliers' handles up and down while pulling the ring towards the pipe's end. If the ferrule isn't tightly secured, it will gradually slide down the pipe until it comes off.

- If the ferrule remains immovable, proceed to the next step.

Secure the pliers around the pipe behind the ferrule if twisting fails. Adjust the pliers' jaws to be slightly wider than the pipe's diameter. Position the pliers behind the ferrule, ensuring the pipe is situated between the jaws. Gently close the pliers around the pipe, allowing for easy movement along its length.

- Exercise caution to avoid over-tightening the pliers, which may hinder movement.

- If a compression nut is present behind the ferrule, slide it against the ferrule before positioning the pliers around the pipe.

Forcefully insert the pliers into the rear of the ferrule. Stabilize the pipe's base with your non-dominant hand to prevent movement or damage. Extend the pliers as far back along the pipe as possible. Then, push them forward forcefully to strike the ferrule. You should observe the ferrule moving slightly down the pipe's length.

- If the ferrule doesn't shift, try striking it again.

- This method is most effective with a longer exposed pipe length, allowing for sufficient force to dislodge the ferrule.

Continue striking the ferrule until it disengages from the pipe. Persist in striking the ferrule with the pliers to propel it down the pipe's length. As the ferrule nears disengagement, cup your hand around the pipe's end. Strike the ferrule a few more times and be ready to catch it as it dislodges from the end.

- If the ferrule remains immovable, using only pliers may not be sufficient to dislodge it.

Utilizing a Compression Ring Puller

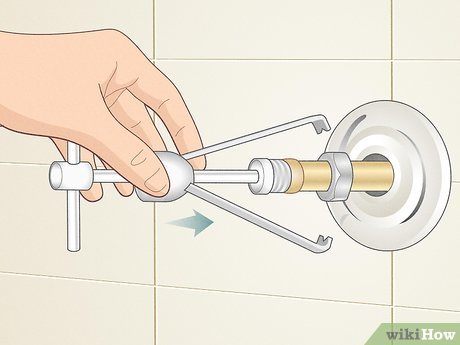

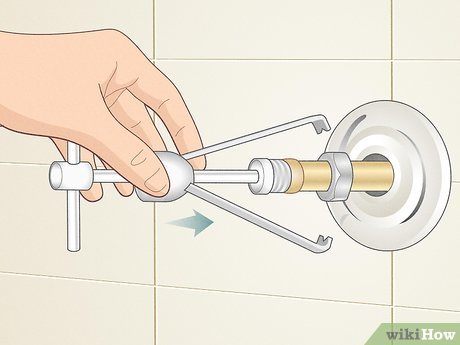

Insert the compression ring puller into the pipe. Compression ring pullers apply pressure to the ferrule's rear to facilitate its movement along the pipe. Align the puller's central column with the pipe and push it in as far as possible. Initially, keep the two arms perpendicular to the pipe to avoid obstruction.

- You can procure a compression ring puller from the plumbing section of a hardware store.

- Some compression ring pullers feature a separate guide for insertion into the pipe. After inserting the guide, thread the puller's central column into it.

Secure the compression nut onto the puller. The threaded end of the compression puller's central column securely holds the nut against the ferrule. Position the compression nut against the threading and rotate it counterclockwise by hand. Continue threading the nut onto the puller until it is hand-tight.

- If your compression puller includes a guide for insertion into the pipe, screwing in the nut may not be necessary. Refer to the puller's manual for guidance.

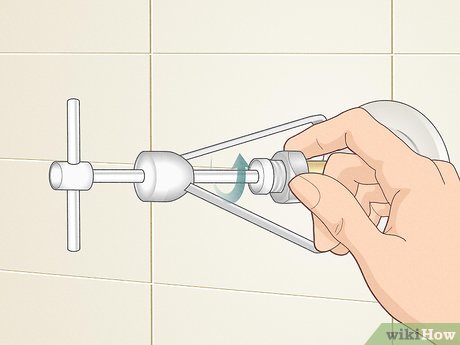

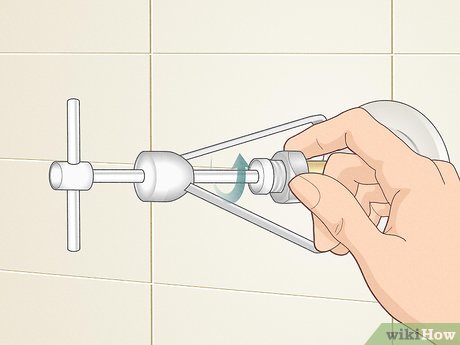

Grip the puller’s arms firmly against the nut's rear. Curve the arms toward the pipe, ensuring they envelop the backside of the nut. Apply pressure to the arms, securing them tightly around the pipe using your non-dominant hand. This allows the arms to exert force, pushing the nut and ferrule away from the pipe.

- If your pipe lacks a nut, you can also press the arms against the back of the ferrule.

- You might be able to lock the arms in position to avoid manual holding. Refer to the puller's instruction manual for proper usage.

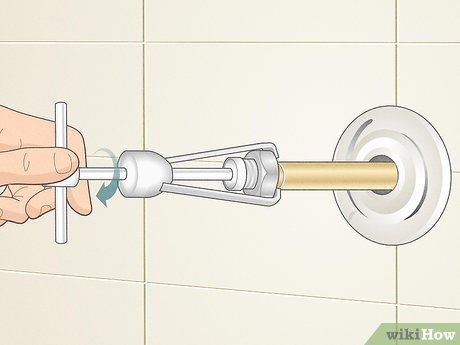

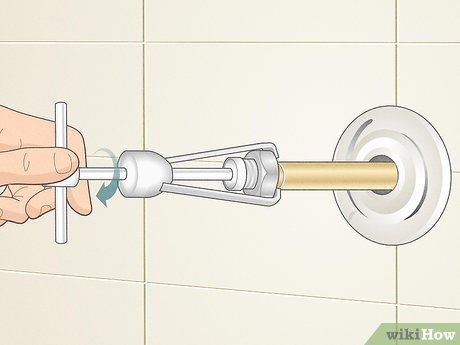

Rotate the puller’s handle clockwise to dislodge the ring. Stabilize the arms with your non-dominant hand while turning the handle with your dominant hand. Continue clockwise rotation to facilitate the movement of the nut and ferrule toward the pipe's end. Upon reaching the end, the ferrule and nut will detach.

- If the ferrule remains immobile, cutting it off may be necessary.

Utilizing a Saw to Cut a Stubborn Ferrule

Create a notch in the ferrule using a hacksaw. Position the hacksaw blade at a 45-degree angle to the side of the ferrule. Apply gentle pressure and saw back and forth to initiate the cut. Proceed cautiously to prevent the blade from slipping, ensuring complete separation of the ferrule.

- An angle grinder is an alternative tool for cutting through the ferrule.

- Periodically pause the sawing process to verify that the pipe remains intact, as damage may lead to future leaks.

Insert a flathead screwdriver into the notch to loosen the ferrule. Place the screwdriver's tip into the cut and press it against the pipe. Rotate the screwdriver half a turn in either direction to disengage the ferrule. Subsequently, withdraw the screwdriver from the notch.

Remove the ferrule from the pipe. Grasp the ferrule, mindful of any sharp edges from the cut, and gently pull it towards the pipe's end. Due to the separation caused by cutting, the ferrule will not be tightly secured to the pipe, allowing for manual removal.

Helpful Tips

Important Warnings

Always turn off your water supply to prevent leaks during work.

Exercise caution when cutting the ferrule to avoid damaging the pipe, which can increase the likelihood of leaks.

Approaching the Ferrule

-

Pair of pliers

-

Towel or bowl

Removing a Ferrule Using Pliers

Utilizing a Compression Ring Extractor

-

Compression ring extractor

Removing a Stubborn Ferrule with a Saw

-

Hacksaw

-

Flathead screwdriver