Silver jewelry offers an attractive alternative to gold, boasting affordability and durability. However, like any precious metal, silver pieces require proper care and maintenance to preserve their beauty. Repairing and cleaning silver jewelry demands precision and may necessitate professional assistance.

Step-by-Step Instructions

Fixing Broken Clasps

Procure two sets of flat nose pliers. These are readily available at hardware stores and jewelry repair kits from hobby shops. Ensure they are small enough for delicate jewelry pieces. If purchasing separately, you'll need two sets to manipulate both ends of the broken clasp.

Acquire a new clasp and additional jump rings. Since your clasp is broken, you'll need to purchase a replacement to attach to your jewelry. Opt for a silver-plated clasp and obtain a few jump rings or connector rings to secure it. These items are available for purchase online or at local hobby and crafting stores.

Unlock the jump rings to remove the old clasp. Using flat nose pliers, grip the ring that connects the clasp to the chain or string. There should be a gap in the ring where it's not fully closed; grip it on both sides of this gap. Pull one side towards you and push the other away to separate them. Then, slide off the old clasp.

Attach the new jump rings and clasp. Replace any damaged or broken jump rings with new ones. Then, on the last jump ring, attach the new clasp before closing the ring. Ensure all jump rings are securely closed. Consider using a hands-free magnifying glass if you have difficulty seeing the clasp and jump rings.

Utilizing a Soldering Torch

Opt for hard silver solder. Ensure you purchase hard solder rather than soft solder. Soft solder won't work with silver jewelry and may cause further damage. Hard silver solder can be bought online or from a local hardware store. You can opt for solder wire or sheets, with sheets generally being more cost-effective and allowing you to cut the required size.

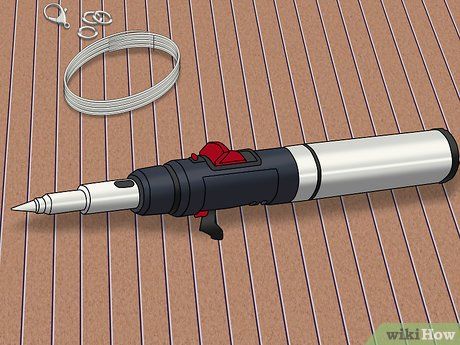

Utilize a soldering torch. Soft solder can be handled with a soldering iron, which operates electrically. Hard solder requires a torch fueled by gas. Butane torches are suitable for typical jewelry repair tasks like fixing jump rings and reattaching small chains.

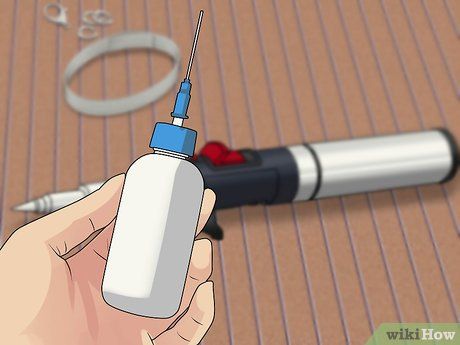

Apply flux during soldering. Flux cleans the metal before soldering to ensure proper bonding and melting. Use liquid flux to coat the surface before starting. You can also opt for flux sprays designed for hard soldering and silver work. Hard soldering may require pickling afterward to clean it.

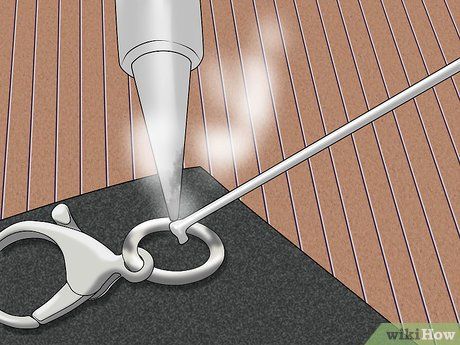

Use the torch to solder the silver pieces. When soldering two pieces together, position the solder wire where needed. Set the torch to its highest temperature and heat the wire until it melts. It will then join with the silver piece being repaired or bonded with another piece. After soldering, rinse the piece in water and pickle it if necessary.

Seeking Assistance From a Jeweler

Consult a jeweler for silver jewelry resizing. Resizing silver jewelry is more challenging than resizing gold. When silver is melted for resizing, it becomes dirty due to oxidation. A jeweler can ensure the piece returns to its original shiny state after resizing. Note that resizing a silver ring with a stone setting may require dismantling the entire ring.

Keep in mind that repairing silver jewelry may require more time and expense compared to gold. Despite silver being less valuable per ounce than gold, its repair process is time-consuming. A jeweler might charge a higher rate due to the time required for repair and polishing to restore its original appearance.

Search for a jeweler equipped with a laser welding machine. Laser welding is the safest method for resizing and working on silver, as it doesn't damage the metal like traditional torch welding. With laser welding, a jeweler can resize a silver ring with a stone setting, which may not be feasible with traditional torch welding.

Managing Tarnish and Scratches

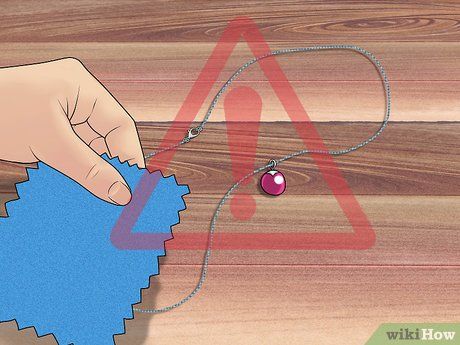

Utilize a specialized silver polishing cloth. These cloths are designed specifically for cleaning and polishing silver. They don't require any liquid cleaner or polishing agent. Simply use the cloth to gently buff away tarnish and restore the jewelry's natural luster.

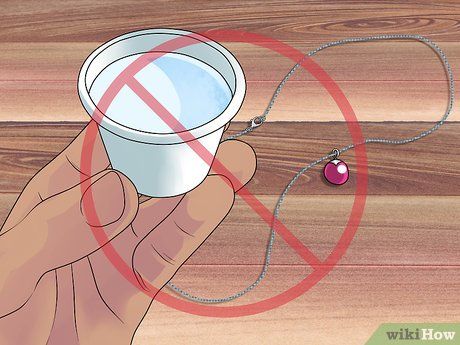

Avoid the use of dips and polishing agents. Liquid polishing agents and dips contain harsh chemicals that could harm plated silver. They should be used in well-ventilated areas due to their hazardous smell. Proper disposal of these chemicals is necessary as they are considered hazardous. Additionally, heavy-duty cleaners can accelerate tarnishing by stripping off the protective surface.

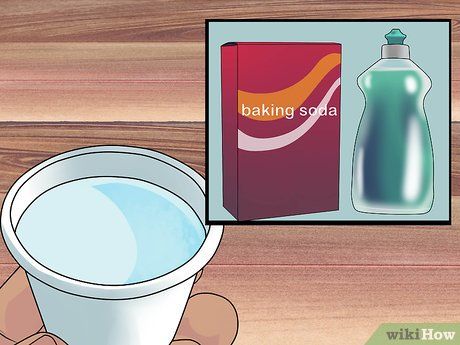

Try a DIY silver cleaner. If the polishing cloth isn't effective, you can experiment with items from your kitchen to clean your silver jewelry. For instance, a mixture of phosphate-free dishwashing soap and warm water or a paste made from baking soda and water can be helpful. Apply a small amount to your jewelry and use it to gently remove tarnish.

Exercise caution when cleaning silver jewelry with precious gemstones. Certain gemstones may require special care during cleaning. If your silver jewelry contains delicate gemstones like pearls, ensure that you only use cleaning or polishing agents that are safe for these components.

Buff out minor scratches with regular toothpaste. Apply a small amount of toothpaste to a cloth and gently rub it into the scratched area using circular motions. Afterward, rinse the jewelry. If the scratch persists, repeat the process. For deeper scratches, consider consulting a jeweler for professional repair.

Helpful Suggestions

-

If unsure, seek guidance from a professional jeweler.