Are your pipes making a racket every time you turn on a faucet? You might be dealing with the pesky phenomenon known as water hammer. Water hammer occurs when swiftly moving water comes to an abrupt halt, like when a washing machine's automatic shut-off kicks in. Rectifying this nuisance could be as simple as shutting off the main valve and purging your plumbing system. If that doesn't do the trick, consider installing an arrestor or bolstering your pipes with straps and insulation for a quieter household.

Here's How

Purging Your Plumbing System

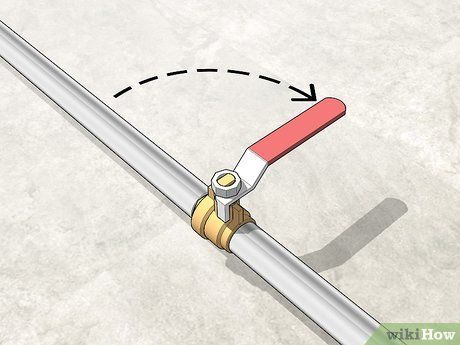

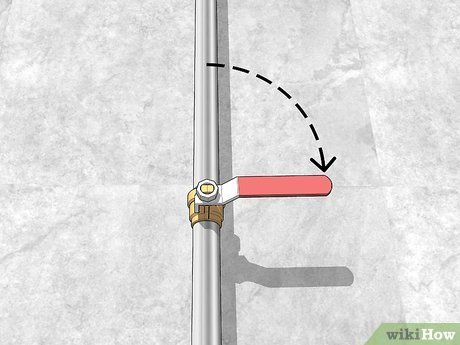

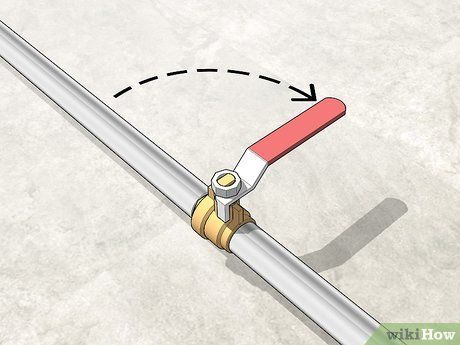

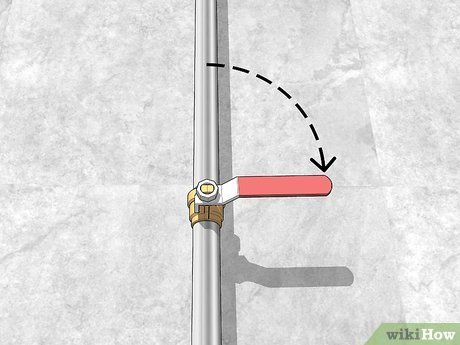

Turn off the primary water valve. This valve is usually operated by either a wheel-handled gate valve or a straight-handled ball valve. Rotate the wheel clockwise until it won't turn anymore for a gate valve, or pivot the lever 90 degrees clockwise for a ball valve.

- The primary water valve is typically situated on an exterior wall of your home, indoors. It's usually at ground level, aligned with your outdoor water meter. You won't find it under a sink or next to your water heater, but it may be concealed behind an access panel.

- In warmer climates, you might find the primary water valve outdoors.

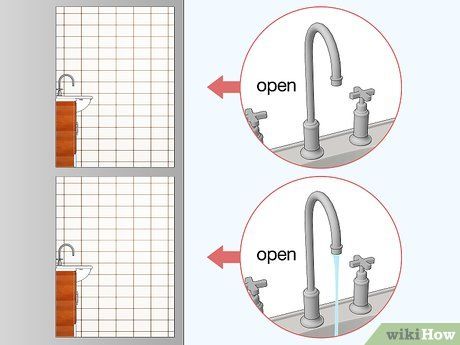

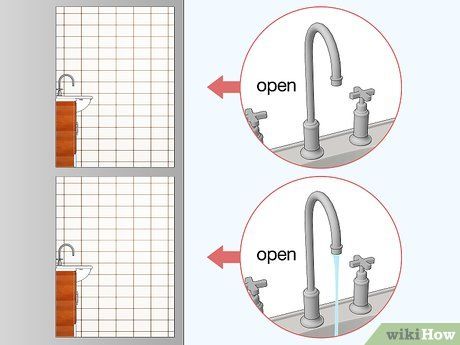

Start by opening the faucet at the highest point and then draining water from the lowest faucet in your house. Begin by opening a faucet on the top floor of your house. Following that, turn on a sink or valve on the lowest level of your house, whether it's the basement or the ground floor. This action alleviates pressure in the pipes and facilitates water drainage.

- Make sure to open both the hot and cold taps to completely drain the pipes.

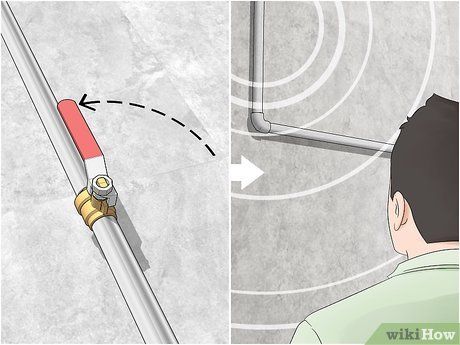

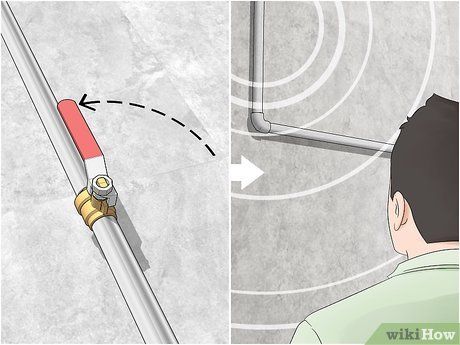

Reopen the main water valve and check if the issue persists. Once the water has been fully drained, close the taps and then reopen the main valve. Turn the main supply line valve counterclockwise to restore water flow. Test to see if the problem persists when you use the problematic tap.

- This method works by draining any water from air chambers and replacing it with air. This cushions the pipes, reducing the likelihood of water hammer.

- If the problem persists, you may need professional assistance to install an air chamber, water hammer arresters, or adjust water pressure reduction valves.

Setting Up Water Hammer Arrestors

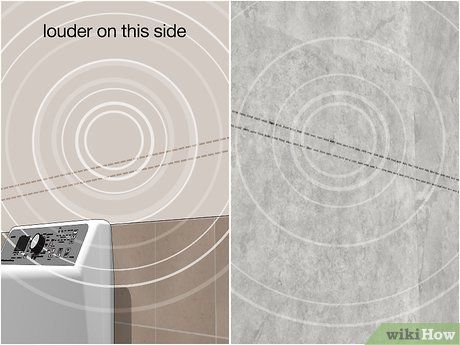

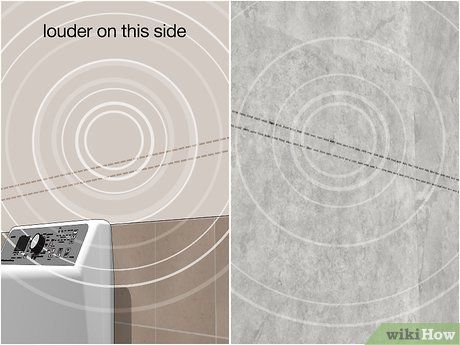

Identify which valve is causing the water hammer. Water hammer typically occurs when a tap is turned off. Listen for the loudest banging noise when you close a tap to determine which supply line is causing the water hammer. This is the line where you'll need to install a water hammer arrester.

- Water hammer is often caused by washing machines and dishwashers due to their quick-closing automatic valves.

Before installing arrestors, shut off the main water supply. Arrestors function by providing an air cushion and absorbing shock when taps are turned off. Prior to beginning the installation process, shut off the water supply to your house. Locate the main water supply and turn the valve clockwise to cut off the water flow. Then, empty the pipes by opening a tap on the lowest level of your house and allowing it to run until the pipes are completely empty.

- The pipes must be entirely empty before installing an arrester.

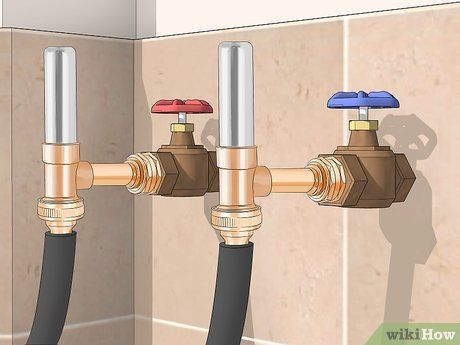

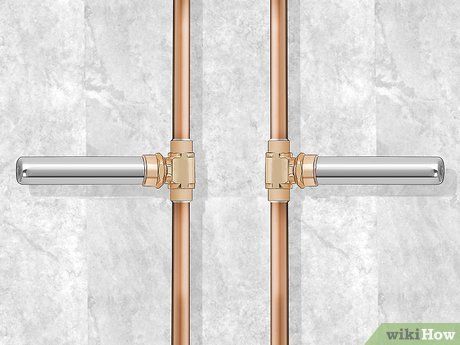

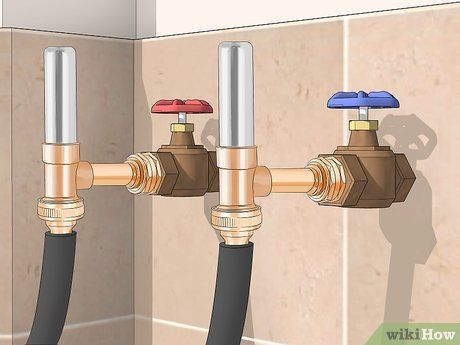

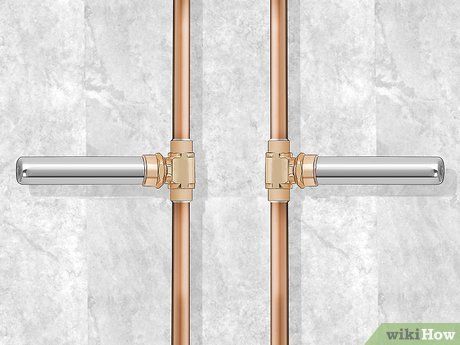

Install two arrestors, one on the cold water line and another on the hot. Safeguard both pipes against water hammer damage by fitting arrestors on both supply lines, even if only one seems to be causing trouble. Whether it's for washing machines or other fixtures, ensure arrestors are installed on both hot and cold taps.

- If you're unsure about installation, consider hiring a professional plumber.

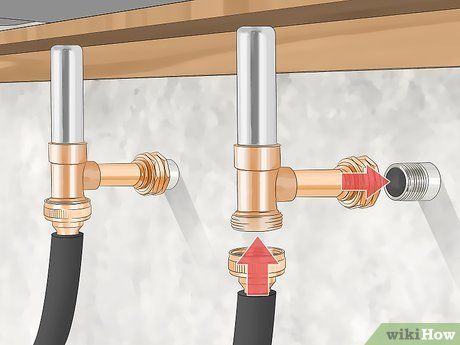

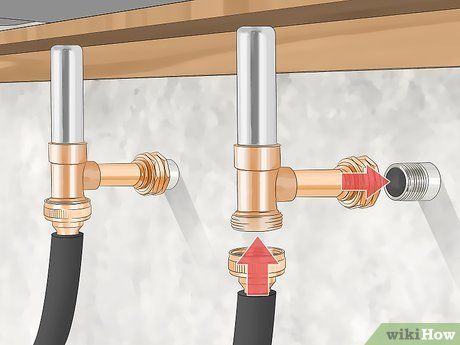

Attach a washing machine arrestor by screwing it onto the supply valve. Look for a specific arrestor labeled 'hose attachment' intended for washing machines, designed to fit where the supply line connects. Disconnect the water supply from the washing machine, then attach the arrestor where the supply line was connected. Finally, reconnect the supply line to the other end of the arrestor.

- Ensure the diameter of the washing machine supply line matches the arrestor's attachment size.

- Remember to distinguish between hot and cold supply pipes when reconnecting.

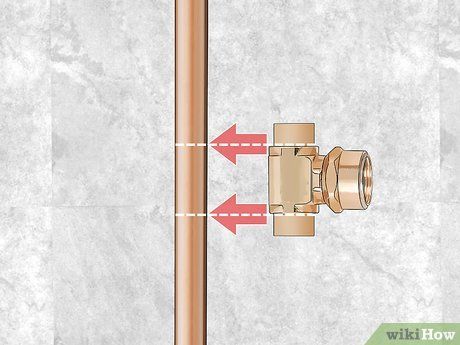

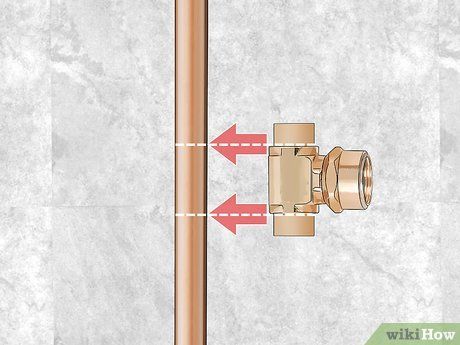

Mark the tap supply lines where arrestors will be installed. For taps other than those on washing machines, installing copper t-fittings and arrestors requires cutting the supply line. Choose a t-fitting that matches the size of the supply pipe and an arrestor that screws into it. Mark the spot where the t-fitting will attach to the pipe using a pencil.

- Select an accessible location for installation, preferably out of sight, such as behind an access panel or in the basement.

- There should be an indentation approximately 1 inch (2.5 cm) into the t-fitting on either side, indicating where to mark on the supply pipe.

Remove the marked section using a pipe cutter. Adjust the pipe cutter to fit the supply pipe size by loosening the screw. Slide the cutter onto the pipe and tighten the screw to engage the blade with the pipe. Rotate the cutter around the pipe to make the cut. For thicker pipes, you may need to repeat the process.

- Alternatively, you can use a hacksaw, though a pipe cutter usually provides a neater cut.

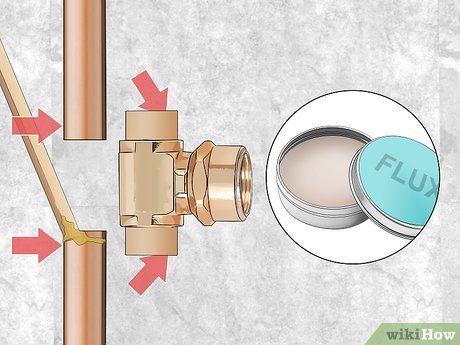

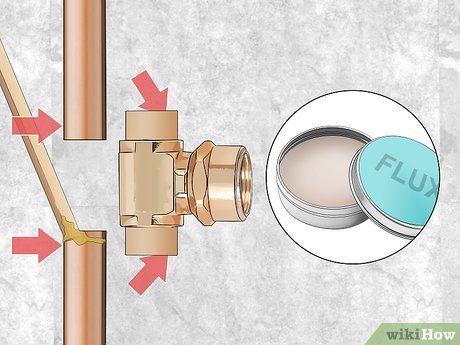

Apply flux to the cut pipe section and slide on the t-fitting. Before soldering the t-fitting to the pipe, apply soldering flux to facilitate the soldering process for copper pipes. Flux enables the metals to meld together while preventing oxidation. Apply flux to the connection point, then insert the t-fitting into the pipe.

- To simplify soldering, clean the pipe with an emery cloth where it meets the t-fitting.

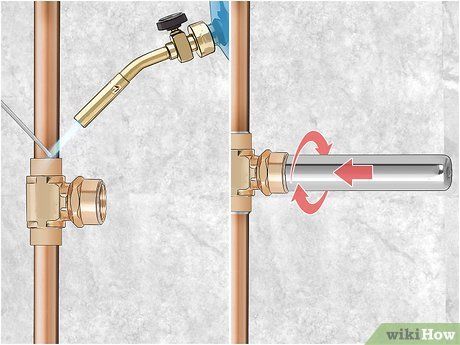

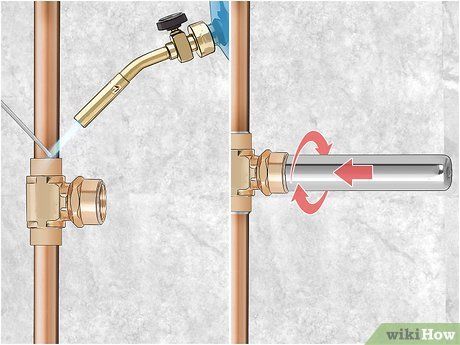

Solder the pipe to the t-fitting and attach the arrestor. Ignite a propane torch by opening the gas tank and using a lighter, if it's a manual torch. Utilize the hottest part of the flame, located at the tip, to heat the flux until it begins to bubble. Ensure even heating by moving the torch around. Apply solder to the opposite side of the pipe from the flame, where it will melt instantly, joining the pipe to the t-fitting. Work around the pipe with the flame and solder to create a secure seal before attaching the arrestor.

- A small propane torch works well for this task.

- Wear safety goggles during soldering.

Repeat the procedure on the opposite side and restore the water supply. Once arrestors are fitted on both hot and cold water lines, reopen the water supply by turning the valve counterclockwise on the main supply line.

- Ensure the t-fittings are thoroughly soldered around the pipe and the arrestor is securely attached.

- To regulate water pressure, confirm your pressure-reducing valve is set below 50 PSI. Adjust the valve by turning it clockwise or counterclockwise until the meter indicates below 50 PSI.

Securing Loose Pipe Straps and Applying Insulation

Locate the source of the pipe rattling. Identify areas where water hammer occurs by listening for the loudest banging noises. Consider adding pipe straps or insulation to stabilize the supply lines, reducing vibrations and water hammer.

- If there's a nearby wooden beam, secure the supply lines with straps.

- If no support beam is present, insulate the pipes instead.

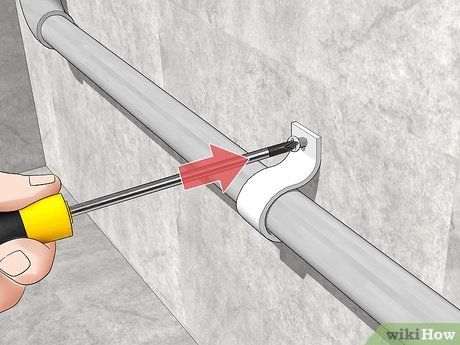

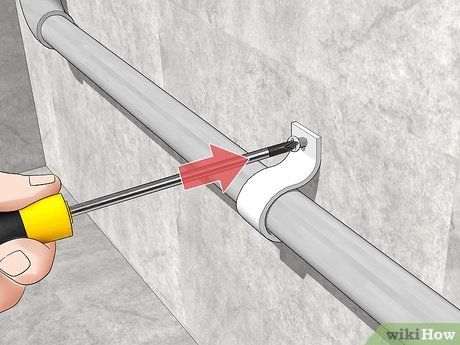

Secure loose pipe straps or install new ones to stabilize the pipes. Tighten any loose straps, or if none exist where the pipes rattle, install straps in exposed areas such as the basement. For added stability, fasten pipe straps around the pipe with U-shaped straps at each floor joist and secure them directly into the drywall.

- Choose metal or plastic pipe straps for this task.

- Avoid using galvanized or steel straps with copper pipes.

Wrap pipe insulation around the supply line to reduce noise. Foam tubes for pipe insulation are available at hardware stores. Typically, they come in 6-foot lengths and are pre-slit. Simply open the insulation along the slit and slide it over the noisy section of pipe. The insulation should fit snugly. If it's too long, trim it with scissors.

- This added cushioning prevents pipes from banging against walls.

FAQs: Fixing Water Hammer

Why do I suddenly experience water hammer?

Water hammer can occur suddenly due to trapped air in the pipes, loose pipes, or worn-out stop valves. Ensure pipes are securely anchored and properly sealed to prevent water hammer.

Is fixing water hammer expensive?

Fixing water hammer yourself is not costly. Water hammer arrestors typically cost between $20 to $30, while pipe insulation is usually under $10.

What causes water hammer in showers?

Water hammer in showers often results from water forcefully hitting a pipe valve upon shutting off. Loose pipes and trapped air can also contribute to this issue.

Helpful Tips

Important Notices

Necessary Supplies

Setting Up Water Hammer Arrestors

-

Water hammer arrestor

-

Pencil

-

Pipe cutter

-

Copper t-fitting

-

Flux

-

Propane torch

-

Solder

Firming Up Loose Pipe Straps and Applying Insulation

-

Pipe straps

-

Screws

-

Screwdriver/power drill

-

Pipe insulation