Among various home appliances, an air conditioner is a specialized device that cannot be casually installed. It demands meticulous research and consideration, spanning from design to technical execution, requiring the investor's thorough commitment. Here, Mytour Supermart will instruct you on the detailed process of installing in-wall air conditioning copper pipes. Let's dive in!

1. Why is it necessary to guide in-wall air conditioning copper pipes?

Installing in-wall air conditioning pipes brings the following advantages to users:

High Aesthetic Appeal: Instead of exposing unsightly connections and tangled wires, opting for in-wall copper pipes allows you to showcase only the unit's evaporator, making it easier to arrange other interior furnishings.

Exceptional Durability: The pipes, hidden within the wall, are shielded from external factors like impact or oxidation. As a result, the lifespan of the air conditioning copper pipes is significantly extended.

Easy Installation: Once you've chosen the position for in-wall copper pipes, concerns about future air conditioner installations fade away. Simply drill brackets for the indoor and outdoor units without the need for disruptive, intricate drilling.

Installing in-wall copper pipes for air conditioners enhances the aesthetic quality of your living space.

2. When to Install In-Wall Copper Pipes

If you're considering installing an air conditioner, the most suitable time to plan and execute in-wall air conditioning copper pipes is during new construction or house renovations. This makes the process convenient, without affecting other furnishings in the house.

Pay attention to the following timings for in-wall air conditioning copper pipes installation:

- Execute after completing the rough wall construction, but before plastering and finishing the floor.

- If you intend to install drywall or engage in any ceiling or column decoration work, it's advisable to perform the pipe installation beforehand.

- For other repair projects, it's recommended to carry out the air conditioning pipe installation after completing other plumbing work to avoid interference with existing pipes.

3. Materials You Need to Prepare

- Copper Pipes: Choosing the right refrigerant copper pipes is crucial. Opt for genuine pipes with a diameter compatible with the chosen air conditioning unit for future installations. The minimum thickness of the pipe should be 0.61 mm to ensure durability when running within the wall.

- Water Pipes: Opt for PVC pipes or externally insulated pipes for construction. The air conditioning water lines can become very cold, leading to condensation during use. Insulation helps protect the copper pipes, preventing leaks and moisture seepage into the walls, which can lead to mold.

- Electrical Wiring: There are two types of wires: power cables and signal cables. Choose wires with appropriate cross-sectional areas for the most efficient operation of the unit.

4. Steps to Guide In-Wall Air Conditioning Copper Pipes

Step 1: Calculate the capacity of the air conditioning copper pipes based on the room's area.

Select a capacity suitable for the room size and intended use. Determine the type of copper pipes needed accordingly:

- For rooms smaller than 15m2, opt for an air conditioner with a capacity of 9000BTU = 1 HP.

- Rooms with an area of 15 – 20m2 should choose an air conditioner with a capacity of 12000BTU = 1.5 HP.

- Rooms with an area of 20 – 30m2 should select an air conditioner with a capacity of 18000BTU = 2 HP.

- For rooms smaller than 40m2, choose an air conditioner with a capacity of 24000BTU = 2.5 HP.

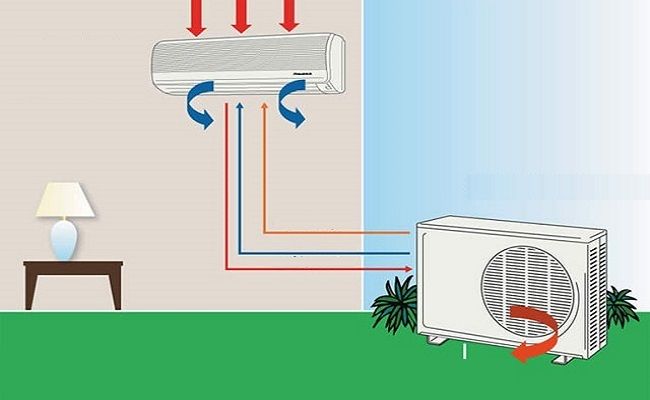

Step 2: Determine the Placement of the Outdoor and Indoor Units

Placement of the indoor unit: Arrange it in a way that prevents direct exposure of cold air to occupants, especially in bedrooms, as it may lead to respiratory issues affecting health. Consider aesthetics and future maintenance convenience for the room.

Placement of the outdoor unit: Choose a well-ventilated location, avoiding direct sunlight on the equipment. Additionally, ensure that the outdoor unit's placement is convenient for future maintenance.

Step 3: Measure the Distance from the Indoor to the Outdoor Unit

Once you've determined the positions of the outdoor and indoor units, measure and cut the copper pipes and electrical wires appropriately. When using copper pipes, select the pipe size corresponding to the capacity of the intended air conditioner, with a minimum thickness of 0.71 mm.

Step 4: Apply Insulation and Wrap the Copper Pipes

Cut the copper pipes, apply insulation, and wrap the insulated pipes for the copper pipes and the bundled cable. The quantity of cables will depend on the type of machine you are using. Leave an excess of 70 – 80 cm at both ends for connecting to the outdoor and indoor units.

Step 5: Perform In-Wall Drilling for the Copper Pipe

When drilling the pipe, ensure to drill to the correct depth of the copper pipe. Avoid drilling too large or too deep, as it may impact the wall's load-bearing capacity.

5. Some Considerations When Installing In-Wall Air Conditioning Copper Pipes

During the process of installing in-wall air conditioning copper pipes, to ensure optimal machine performance, pay attention to the following issues:

- Ensure effective insulation for copper pipes, synthetic leather, and electrical wires, with insulation extending from the indoor unit to the outdoor unit.

- Connect the protective switch to the location of the indoor unit to ensure a stable power supply for the air conditioner.

- Maintain a distance of about 5m between the outdoor and indoor units to avoid reducing the air conditioner's efficiency.

- Prefer using seamless pipes without welding when running pipes in-wall. In case welding is necessary, ensure the joints are securely sealed.

- Arrange the indoor and outdoor units in harmony with the aesthetic value of the house and ensure compliance with technical standards.

After the insights shared above, it is hoped that you have gained valuable information on the most effective installation of in-wall air conditioning copper pipes.