Preparation

Getting Started with Your Materials

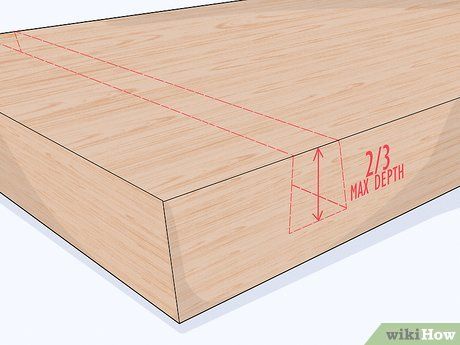

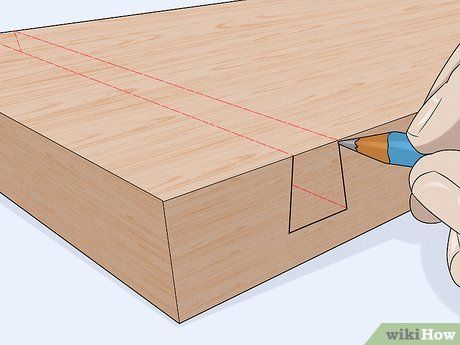

Sketch out the dimensions and position of your cut using a pencil. After finalizing the measurements for your joint, draw two lines of corresponding width along the surface of your socket piece with the aid of a ruler or straightedge. These guidelines will prove invaluable when it's time to guide your router for the necessary cuts.

- Typically, the socket is cut into the wide side of one board and the dovetail into the end of the other. This configuration allows the two pieces to interlock at a right angle.

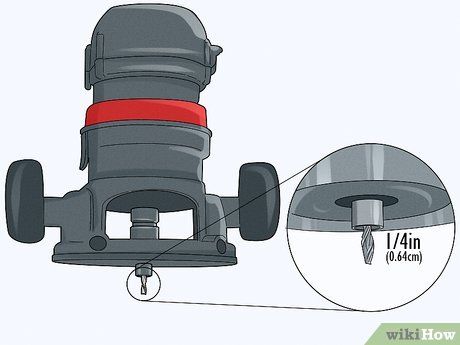

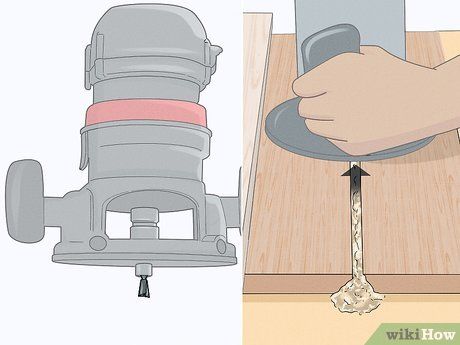

Outfit your router with an appropriate straight or spiral downcut bit. Insert the narrow end of the bit into the collet (the metal sleeve that secures the bit) on the circular base plate of the tool. Tighten the locking nut on the collet by turning it clockwise by hand until it's snug, then use a wrench to secure it fully.

- A 1⁄4 in (0.64 cm) bit is recommended for routing standard 3⁄4 in (1.9 cm) stock boards and sheets.

- A router is a woodworking tool designed to carve out narrow sections along the surface of wood. Handheld routers are common, but there are also router table setups available for increased power and precision.

Tip: Aim to choose a bit wide enough to create a clean opening in one go. This will reduce errors and save you from having to make corrections later on.

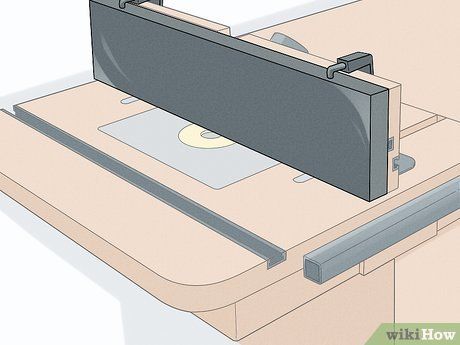

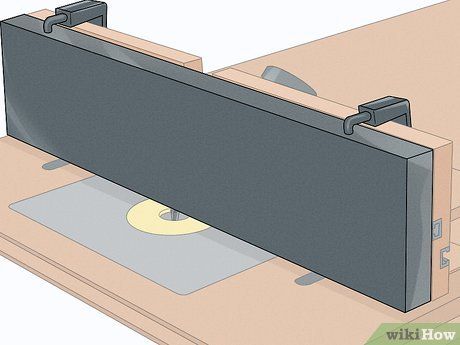

Arrange a fence or edge guide just beyond your marked lines. Align the guide or fence so that the router bit sits centrally between the width lines you traced earlier. Either of these tools will help direct and steady your cuts.

- Router tables typically come with adjustable fences for quick setup. For handheld routers, you'll need to purchase or rent a separate edge guide. A basic edge guide can be found at hardware stores or home improvement centers for around $15-20.

- If you're inclined, you can craft your own measured edge guide using a long piece of scrap wood, an inexpensive piano hinge, and some wood screws.

Prepare for Routing the Socket

Put on earmuffs and protective eyewear. When using a router, expect loud noise and the possibility of wood shards flying. Protect your eyes from splinters and prevent hearing damage. Consider wearing work gloves, but remember this may slightly reduce control.

Guide the router along the marked area of the wood. Turn on the router and align the base plate with the piece and edge guide or fence. Move the router smoothly from left to right or push the piece along if using a router table. Left-handed users may prefer moving materials from right to left. The aim is to remove excess wood before detailed work.

Swap the straight bit for a dovetail bit and repeat. Continue moving the router or piece along straight, ensuring contact with the edge guide or fence. The dovetail bit will shape the dovetail with its tapered form. Adjust the dovetail bit height to match the socket's intended depth. Consider making light scoring cuts if cutting dovetails for the first time.

Turn the piece 180 degrees and make a final pass to finish the socket. Rotate the piece without flipping it and adjust the edge guide or fence as necessary. Carve the dovetail into the opposite side of the groove for a symmetrical socket. Take your time to avoid tear out damage and ensure a proper fit between pieces.

Crafting the Tenon

Keep the dovetail bit attached to your router. Consistency is key, so stick with the same bit for both pieces to ensure a perfect fit.

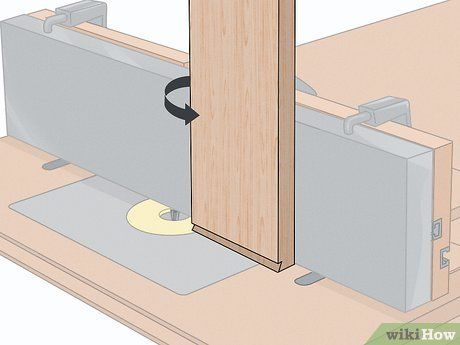

Add an auxiliary fence to your main router fence. Use a premade auxiliary fence or a flat scrap of wood to extend the height of your fence, providing support for taller pieces.

Position your piece vertically on your work surface. Secure it against the fence, ensuring flush alignment before cutting.

Guide the rear edge of your piece along the fence to start cutting. Slowly push the wood away while pressing it into the fence to create angled surfaces that match the socket.

Rotate your piece 180 degrees and repeat the cut on the other side. Ensure symmetry and a tight fit by repeating the process for both sides of your piece.

Continue trimming both sides of the tenon until it fits perfectly. Adjust the fence to expose more of the bit, then proceed with your cuts. Gradually remove material until the tenon matches the socket in width and depth.

Leave your fence in the optimal position for future cuts if you're making multiple joints.

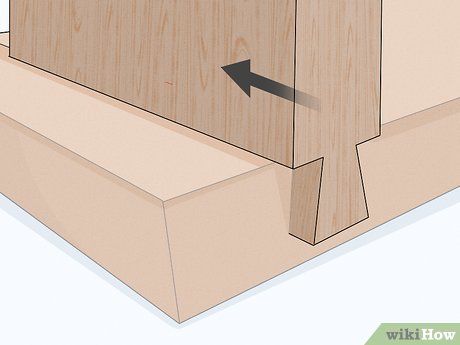

Insert the completed dovetail into the socket to assemble the joint. Align the edges and gently press or tap to fit, ensuring correct sizing and cutting. Optionally, apply wood glue for added strength, but remember it will prevent separation.

Tips

- Sliding dovetails offer seamless and inconspicuous joints.

Warnings

- Routers utilize sharp, high-speed rotating metal components. Practice the same safety precautions as with other powerful tools like saws and drills.

Things You’ll Need

Setting up Your Materials

- Edge guide or adjustable guide fence

- Straight or spiral downcut bit

- Dovetail bit

- Pencil

- Ruler or straight edge

- Earmuffs

- Safety glasses or goggles

- Protective gloves (optional)

Routing the Socket

- Handheld router or router table

- Wooden boards or sheets

Fashioning the Tenon

- Wooden boards or sheets

- Handheld router or router table

- Edge guide or adjustable guide fence

- Dovetail bit

- Auxiliary fence or scrap wood

- Hand clamps

- Push block (optional)

- Scrap board (optional)

- Medium-grit sandpaper (optional)