Choosing the right air compressor can be bewildering if you're unsure what features to prioritize. Air compressors are the backbone of numerous tools across various applications. To ensure you make an informed decision, it's crucial to equip yourself with the necessary knowledge. Here's a comprehensive guide to help you navigate through the process.

Key Steps

Understanding the Fundamentals

Evaluate the specific needs of the equipment you intend to operate. Will you use the compressor to power machinery, pneumatic tools, or for tire inflation? Opting for a compressor with a tank is advisable if you're utilizing tools with high flow requirements. Conversely, a tankless portable compressor may suffice for tasks like airbrushing or tire inflation. Despite the continuous operation of tankless compressors due to the absence of a storage tank, noise levels remain minimal owing to their compact size.

- It's crucial to assess the pressure and volume requirements of your tools. Heavy-duty tools demand higher pressure and volume. Failure to select an adequately sized compressor may lead to downtime while waiting for the tank to refill, hampering your productivity.

- For instance, if you're using a portable air compressor for airbrushing, a small tank capacity of around 5 liters (1.3 US gallons) and sustained air pressure of approximately 30 psi would suffice.

Understanding the Various Compressor Types

Focusing on Specific Factors

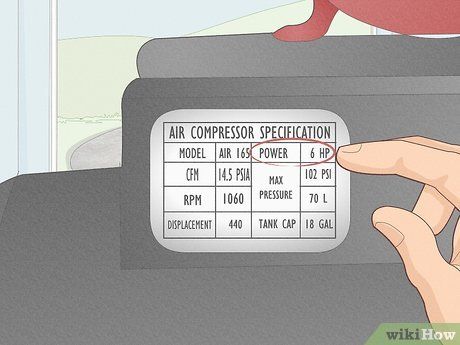

Examining the Horsepower (HP) Rating

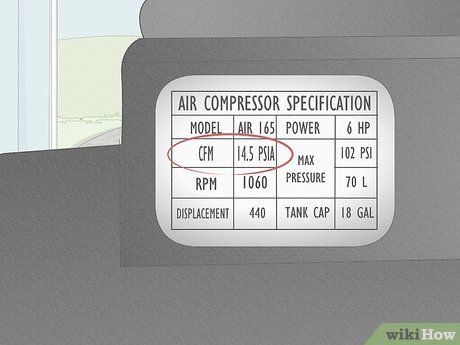

Exploring Cubic Feet per Minute (CFM)

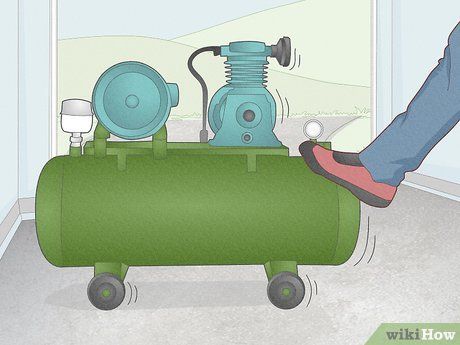

Considering Mobility and Space Requirements Are you able to transport or move the compressor easily? Whether it's a compact, portable unit or a larger, stationary one, assess its mobility. While portability offers convenience, if the compressor primarily remains stationary, you might opt for a higher-capacity unit and use longer hoses as needed. Determine whether the compressor needs to reach a roof-mounted nail gun or simply inflate tires in the garage.

Assess Your Power Supply Options Will you have consistent access to electricity, or will you often work in areas without power? If electricity is readily available, an electric motor-driven system is suitable. Most electric air compressors operate on 110V (US), although larger models may require 240V. Ensure you have the necessary power source before making a purchase.

- Alternatively, explore mobile air compressor solutions. These can run on gasoline or diesel engines, integrate with a vehicle's engine, or utilize hydraulic ports or other power take-off (PTO) mechanisms. Fortunately, there are numerous modern power options for air compressors.

Determine the Appropriate Tank Size for Tank-Mounted Compressors If you'll use the air compressor sporadically, such as for nail gun applications, a smaller tank suffices. However, for prolonged usage periods, opt for a larger tank. Tank capacity is typically measured in gallons.

Useful Tips

-

While oil-free compressors may seem appealing initially, they can be excessively noisy in practical settings. Some users resort to wearing hearing protection or vacating the area when the compressor is in operation. Despite this, oil-free compressors deliver cleaner air compared to oil-lubricated ones. However, proper filtration can mitigate this noise issue. Additionally, pneumatic tools often necessitate occasional lubrication.

-

Oil-lubricated compressors typically boast superior durability and quieter operation than their oil-free counterparts.

-

Assess your requirements before selecting a compressor to ensure compatibility.

Important Warnings

- Ensure portable air compressors are positioned securely to prevent falls.

- Exercise caution with air tools as they pose potential hazards. Familiarize yourself with all manuals and prioritize safety.