1. BMW M57 Diesel Engine

The BMW M57 Diesel Engine was first introduced in the US in 2009, available in the 335d sedan and X5 SUV models. This 3.0L direct injection, six-cylinder engine boasts a 3.31-inch bore and a 4-inch stroke. It produces 265 horsepower at 4,200 rpm and 425 lb-ft of torque at 1,750 rpm. Despite its impressive specs, testing revealed that it could achieve speeds of over 95 mph in under 14 seconds, demonstrating its underrated performance. The engine delivers rapid acceleration and maintains a strong power curve up to 5,000 rpm, thanks to its unique sequential turbocharging system.

Within the M57's aluminum block, you'll find a forged steel crankshaft, supported by a two-bolt main cap. Much of its incredible torque-handling capability comes from the forged steel connecting rods. These rods are twice the size of those found in BMW's N54 twin-turbocharged 3.0L engine, which produces 402 horsepower. The M57's connecting rods are paired with cast aluminum pistons, direct injection rings, and a composite intake manifold mounted on the engine head.

2. Lexus 2UR-GSE Engine

The 2UR-GSE is a 5.0L V8 gasoline engine with a 90-degree 'V' angle, first introduced in the Lexus IS F. Although derived from the related 1UR-FSE engine, the 2UR-GSE underwent significant modifications to cater to more performance-oriented applications. Notably, the cylinder head for the 2UR-GSE was developed by Yamaha, and changes include a wider valve angle, high-flow intake ports, and larger, higher-mounted ports. The 2UR-GSE's 4969cc aluminum alloy block features a 94mm bore and 89.5mm stroke, with a bore pitch of 105.5mm and a pillar distance of 21mm. The block's outer surface is reinforced with ribs for enhanced rigidity.

Inside the bores, the 2UR-GSE engine uses thin-walled cast iron liners with a knurl pattern that provides larger, uneven surfaces for better adhesion between the liners and the block. This improvement enhances heat dissipation and reduces thermal distortion of the bores. Additionally, the block includes drilled coolant passages between each bore. The engine features a forged steel crankshaft with six drilled balance weights and five main bearings.

The crankshaft bearings are made of aluminum alloy, and the bearing surfaces are coated with a plastic layer to enhance wear resistance and shock absorption. The crankshaft bearing caps are secured with four bolts, with different-sized plastic inserts on the inner and outer sides to firmly hold the journals. Each crankshaft cap is tightened from the side for improved reliability. To reduce noise and vibrations, the crankshaft pulley is equipped with a dual-twist damper.

3. Honda K Series Engine

The Honda K-Series Engine is a 4-stroke, 4-cylinder engine introduced in 2001. The K series is equipped with a DOHC valve system and utilizes roller bearings to reduce friction. This engine features a coil-on-plug ignition system, eliminating the need for a traditional distributor. Instead, the system is controlled by a computer, allowing the ECU to adjust the timing based on various sensor inputs. The cylinders are lined with cast iron sleeves, similar to the B-series and F-series engines, as opposed to the FRM liners found in the newer H-series and F-series engines, like those in the Honda S2000.

Similar to the B-series, the K-series engine features two short blocks with identical designs, the only difference being the deck height. The K20 uses a short block with a deck height of 212mm, while the K23 and K24 have a deck height of 231.5mm. Two versions of the Honda i-VTEC system are found in the K series, both of which can be equipped with Variable Timing Control (VTC) on the intake camshaft. On engines like the K20A3, the VTEC system operates only on the intake cam, where, at low rpm, only one intake valve is fully open while the other remains slightly open to create a swirl effect in the combustion chamber, improving fuel atomization.

4. Toyota 2AR-FE Engine

The 2AR-FE was introduced in 2008 as a replacement for the 2.4L 2AZ engine. It offers improved fuel efficiency while maintaining similar power output to its predecessor. This improvement was achieved through the use of modern technologies during its development. Alongside the 2.5L engine, Toyota also produced a 2.7L version of the 1AR-FE engine. Like its predecessor, the 2AR-FE has an aluminum block with thin cast iron liners inside. The block is not serviceable, and the liners cannot be replaced. Inside, a forged steel crankshaft is positioned 10mm closer to the exhaust (an offset crankshaft).

The crankshaft is fully balanced and features a counterweight to reduce vibrations. It drives two balance shafts through a gear inside the oil sump, eliminating engine vibration. Significant changes in the 2AR-FE are found in the cylinder head. It features a DOHC 16-valve design made of aluminum alloy and includes hydraulic lifters (not available in the 2AZ). There are two camshafts, each equipped with Toyota’s Dual-VVTi system for variable valve timing. The engine uses roller followers for the valve system and was developed with low-friction technologies, including pistons with low-tension rings.

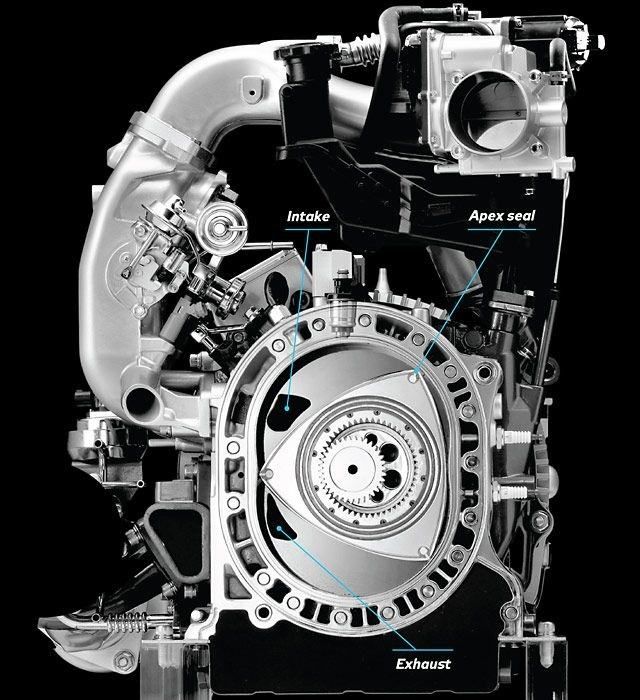

5. Mazda Renesis Rotary Engine

The 13B-MSP Renesis is a revolutionary rotary engine, used in the Mazda RX-8 from 2003 to 2011. Designed with the goal of maintaining the performance of the turbocharged 13B-REW engine while improving fuel efficiency and reducing emissions, the Renesis name is a fusion of Rotary Engine (RE) and Genesis. The MSP abbreviation stands for Multi Side Ports, a feature that distinguishes it from Mazda's previous rotary engines. Unlike the 13B-REW, the 13B-MSP is a naturally aspirated (NA) engine with a 1308cc displacement (79.81 cu in), maintaining the same rotor radius and length as its predecessor.

Each combustion chamber has a volume of 654cc. The biggest upgrade is that the 13B-MSP features two exhaust ports per rotor, as opposed to the single peripheral exhaust port per chamber found in the RX-7’s rotary engine. This change reduces flow resistance, almost doubling the exhaust port area compared to the 13B-REW, eliminates intake/exhaust crossover, and boosts thermal efficiency, power output, and fuel economy. This ensures that exhaust gases are not transferred to the next combustion cycle, resulting in more stable and efficient combustion. The 13B-MSP was offered in both standard and high-performance versions, with the standard version featuring two intake ports per chamber, and the high-performance version having three intake ports (main, secondary, and auxiliary) per chamber.

6. Honda B-Series Engine

For over 12 years, the legendary Honda B-Series has gained widespread attention in the tuning community. While it may not be the most sought-after engine, its iconic status and its place as a JDM legend cannot be overlooked. The B-Series engines, produced from 1989 to 2001, feature both DOHC and SOHC inline-4 configurations. Despite some of these engines being over thirty years old, their popularity continues to endure.

In an era when American car manufacturers were known for large, low-power engines, the compact B-Series could make its bigger competitors look bad by delivering an impressive 116 horsepower per liter. Coupled with its remarkable power output in such a small package, the B-Series also earned a reputation for reliability, earning the “bulletproof” label for Honda engines. These high-performance engines brought power, reliability, and affordability to the masses, all backed by Japan's renowned engineering quality.

7. Volkswagen 1.4L Twincharger TSI Engine

The engine has been praised for its strong torque characteristics since its debut in 2007, offering significantly reduced low-end torque thanks to the supercharger, but also delivering impressive peak power at higher revs due to the turbocharger. Volkswagen is reportedly working on a new turbocharged engine to replace the popular one. For two consecutive years, the 1.4L TSI Twincharger engine from Volkswagen was crowned the winner at the International Engine of the Year Awards.

Beating 66 competitors, the Fiat 1.4L MultiAir Turbo (used in the Alfa Romeo MiTo/Giulietta) claimed the title of Engine of the Year. Surprisingly, the judges ranked it ahead of Ferrari’s 4.5L V8 engine (from the 458 Italia) and BMW’s 4.4L V8 (from the X5M/X6M). Volkswagen’s engineers have reported that using a new single-turbo engine could help reduce costs without sacrificing performance or efficiency. The new engine is expected to produce similar, if not better, power and torque figures while still maintaining relatively low fuel consumption.

8. General Motors LS Engine

The General Motors LS engine is regarded as one of the best V8 engines ever produced. Manufactured for over 20 years, it remains in use today, having consistently delivered power, durability, and reliability. The LS engine has powered some of the world’s best-performing vehicles and has become a perfect candidate for engine swaps due to its compact size, reliability, and relatively affordable cost. GM continues to produce these engines because of their excellence, meaning anyone looking for one can easily find one.

Another key point is that replacement parts are widely available, especially if you’re looking to significantly boost engine power. Over the 20 years of production, GM has produced a variety of LS engines, starting with the LS1 5.7L 345-hp engine in the 1997 Corvette C5. GM also made several truck engine variants, including LR, LM, LY, LC, and LQ. The 2005 model year introduced the first of the Generation IV blocks, featuring more aluminum construction, a new intake design, lighter exhaust components, and improvements like demand-based replacement, variable valve tuning, and larger bore sizes.

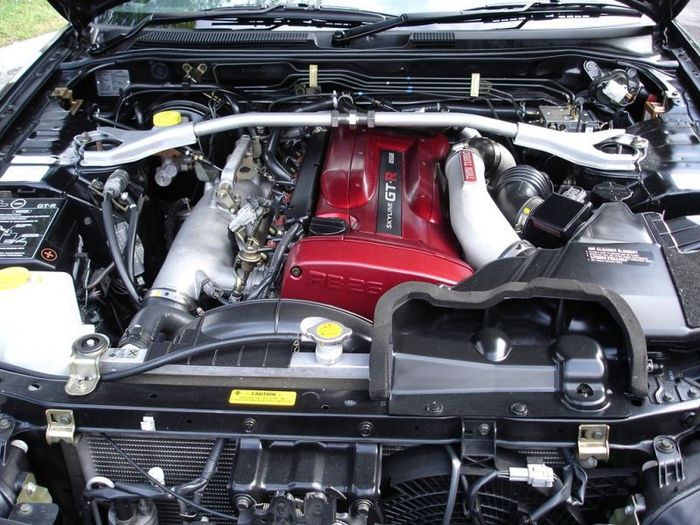

9. Nissan RB26DETT Engine

The RB26DETT engine powered some of the most iconic cars, from the R32 to the R34 GT-Rs, making Nissan's vision of an inline six-cylinder powerplant a dream for car enthusiasts and tuners alike. The RB26 is a derivative of the RB25 that was fitted to the Skyline GT-S. Widely regarded as a technical marvel, much like the 2JZ, the RB26 is known for its durability and over-engineered design. However, Nissan had different plans, designing the RB26 with motorsport in mind, leaving ample room for higher output potential.

Introduced in 1989 and produced until 2002, the RB26 was a direct descendant of the RB25DET. Unlike its predecessor, the RB26 features a block without oiling ports. It boasts a 6-cylinder inline configuration with an 86.9 mm bore, a 73.7 mm stroke, and a compression ratio of 8.5. All RB series engines, including the RB26DETT, were produced in Yokohama, Japan. Nissan used the RB26 in the R32 and R33 Skyline GT-Rs, with a revised version appearing in the R34.

10. Ford EcoBoost 1.0L

The compact 1.0L petrol engine powering Ford vehicles, including the new Fiesta, has triumphed over competitors from premium and supercar brands, claiming the coveted 'Oscars' of the engine world for three consecutive years. Ford's 1.0L EcoBoost engine reduces fuel consumption without compromising on power, earning the title of International Engine of the Year in 2014 for its impressive driving dynamics, performance, efficiency, refinement, and technology. First introduced in Europe in 2012 with the Ford Focus, the 1.0L EcoBoost is now available in 9 additional models: Fiesta, B-MAX, EcoSport, C-MAX, Grand C-MAX, Tourneo Courier, Tourneo Connect, Transit Courier, and Transit Connect.

The EcoBoost 1.0L has won 13 major awards, including seven International Engine of the Year titles across three years, with the Best New Engine Award in 2012. In addition, the engine was honored with the 2013 Paul Pietsch International Technology Innovation Award in Germany, the Dewar Trophy from the Royal Automobile Club in the UK, and the Breakthrough Award from Popular Mechanics in the US. Ford also made history as the first automaker to earn a spot in Ward's 10 Best Engines list for a three-cylinder engine.