1. De Nhat uPVC Pipe Adhesive

De Nhat uPVC Pipe Adhesive is one of the leading brands in Vietnam, widely trusted by consumers and commonly used in the market. This adhesive is known for its high quality and provides a strong, leak-proof connection between pipe fittings. When the adhesive dries, it forms a durable bond that holds the two pipe ends securely together. It's fully waterproof and resistant to peeling or detaching when exposed to water, ensuring smooth fluid flow through the pipes. Additionally, once dry, it leaves a clear, aesthetic finish, making your pipes look more polished. The product is perfect for connecting PVC joints, pipes, and other accessories.

De Nhat uPVC Pipe Adhesive is manufactured according to strict standards and comes in convenient tubes of various sizes, including 15gr, 30gr, 50gr, 100gr, and 1000gr, to suit different needs.

2. Seaglue SG 95 Plastic Adhesive

Seaglue SG 95 Plastic Adhesive is made from organic bonding agents, giving it exceptional adhesive strength on various surfaces. It can be used on materials such as PET, PP, OPP, PVC, EVA, Vinyl, hard plastics, and flexible plastics. It also bonds well with other materials like wood, mica, simili, tarpaulin, foam, and rubber.

Seaglue SG 95 stands out with several advantages over other adhesives available in the market:

- Light odor and capable of withstanding temperatures up to 70-80°C, ideal for use in harsh environments

- Strong adhesion on a variety of materials

- Even difficult-to-bond materials can achieve excellent adhesion

- Good flexibility and elasticity once dried

- Clear finish, enhancing aesthetic appearance after bonding

- Water-resistant, ensuring no peeling when exposed to water

- Perfect for applications in environments that require frequent submersion in water

- High viscosity

- Dries faster and bonds more effectively than SG-45

- Easy to use, facilitating quick application

- Affordable and cost-effective

- Safe for user health

How to use Seaglue SG 95 Multi-Purpose Plastic Adhesive:

- Step 1: Clean the surface of the material to be bonded. After washing, dry it completely, avoiding touching it with bare hands to prevent transferring oil.

- Step 2: Lightly sand the surface of the plastic to enhance the bond with Seaglue SG 95

- Step 3: Use a small brush to evenly apply a layer of adhesive on both surfaces to be joined

- Step 4: Gently press the two materials together, ensuring they are firmly held and any air bubbles are eliminated. Wipe away excess adhesive unless using acrylic glue, which evaporates on its own.

- Step 6: Keep the materials firmly in place. Avoid applying pressure or heat for at least 24 hours after bonding, even if the materials seem to be securely attached.

3. PVC Adhesive – P-638

With the growing demand for PVC sheet installation, "P-638 Adhesive" was developed specifically for bonding PVC materials. This adhesive is designed solely for use with PVC (including PVC trims); it cannot be used on wood, metal, or other materials.

Ingredients: PVC Adhesive – P-638 consists of PVC powder, Cyclohexanone solvent, and other additives. It is manufactured in Vietnam and has a shelf life of 6 months from the time of use (no more than 12 months from the production date).

Advantages:

- This adhesive offers superior bonding strength compared to many others on the market (which often contain additives for other materials). Users will experience the solid, durable connection between PVC sheets when using P-638.

- Additionally, P-638 is highly water-resistant and can withstand high pressure.

Instructions for Use:

- Clean dust, grease, and impurities from both PVC surfaces to be bonded.

- Apply an appropriate amount of adhesive (avoid excessive application to maintain aesthetics).

- Wait for 5 to 7 seconds, then firmly press the two PVC surfaces together to ensure maximum adhesion.

- The adhesive sets in 15 minutes, and the bonded product should be used after 12 hours.

Note: Always tightly seal the cap after use – keep out of reach of children – avoid direct skin contact during use, and do not expose to flames.

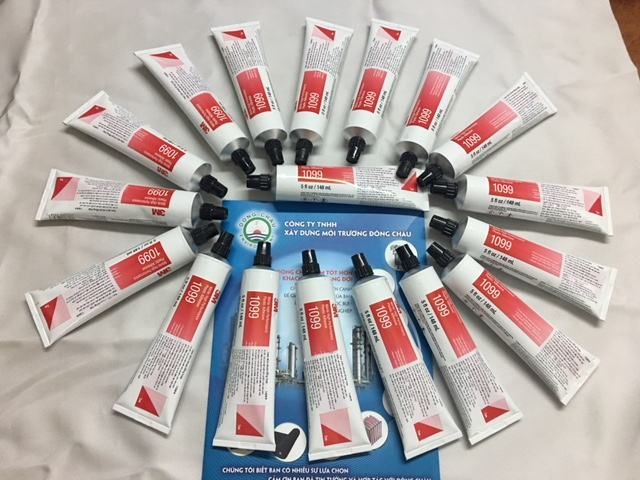

4. 3M™ Scotch-Weld™ Adhesive 1099

3M™ Scotch-Weld™ Nitrile Adhesive 1099 is a fast-drying liquid adhesive that can be cured with heat when it becomes hardened. It is versatile, bonding various materials such as metals, plastics, fabrics, and rubber. It is resistant to harsh weather conditions, oils, water, solvents, and chemicals. The adhesive is designed to withstand temperatures from -18°C to 82°C.

Applications:

- Bonds a wide range of materials: Metals, plastics, fabrics, rubber, and more.

- Resistant to harsh environmental conditions, oils, water, solvents, and chemicals.

- 3M Industrial Adhesive 1099 offers excellent temperature resistance: -18°C to 82°C.

- This adhesive dries quickly and can be cured with heat if it hardens prematurely.

- Provides strong, durable bonds.

- Resists harsh weather conditions, oils, water, and fuels.

- Ideal for most vinyl extrusion bonding and upholstery applications.

- Works well with various fabrics.

- 3M 1099 Adhesive offers exceptional resistance to weather, oils, water, and fuels, making it suitable for outdoor and industrial use.

- Perfect for high-temperature industrial applications.

- Resists oils, fuels, and most solvents under challenging environmental conditions.

- Great for bonding ABS, nylon, polycarbonate, vinyl, and other materials.

- Excellent for extrusion bonding and laminating fabrics, foams, and various flexible and rigid plastics.

- Adheres well to heat exchange plates.

- Available in sheet and disk forms, designed to deliver optimal thermal performance when transferring heat between liquids, steam, and other materials in various heat exchange applications.

5. Tien Phong PVC Pipe Adhesive

Tien Phong PVC Pipe Adhesive is a solution made from a blend of Cyclohexanone solvent, Polyvinyl Chloride (PVC) powder, and additives. The inclusion of PVC powder enhances the adhesive's elasticity, making it suitable for pressure-bearing connections. The adhesive has relatively low heat resistance, allowing for easy removal of excess glue with heat.

This adhesive is specifically designed for bonding PVC pipes (primarily used to connect two sections of pipe or to join PVC pipes to fittings) in various situations such as:

- Fixing leaks from cracked or damaged pipes.

- Joining broken sections of piping.

- Connecting and securing joints or branches in plumbing systems.

- For small pipe repairs, Tien Phong PVC Pipe Adhesive can save you significant costs on replacement, as it allows you to reuse existing pipes instead of buying new ones, saving both money and time.

Instructions for using Tien Phong PVC Pipe Adhesive:

- Step 1: Cut the pipe ends squarely, ensuring the pipe ends and the socket are intact and undamaged. Bevel the pipe edge to prevent sharp edges from pushing the adhesive out.

- Step 2: Measure the required joining length on the pipe end based on the length of the fitting to be joined and mark it with a pen.

- Step 3: Clean the pipe surface and the fitting using a soft, clean cloth.

- Step 4: Quickly apply the adhesive evenly to the entire area to be joined using a brush. The maximum application time is 30 seconds.

- Step 5: Push the pipe end firmly into the fitting up to the marked line, holding it in place to ensure it doesn’t push back out. Hold the connection tightly for at least 30 seconds until the bond sets.

- Step 6: Wipe away any excess adhesive from the outside and inside of the joint.