Is your trailer making unsettling noises as it moves? It's likely time to swap out those worn-out ball bearings. But don't fret, it's a breeze! In this comprehensive guide, we'll walk you through the process step by step. Say goodbye to rough rides and hello to smooth sailing!

Step-by-Step Instructions

Removing the Hub and Bearings

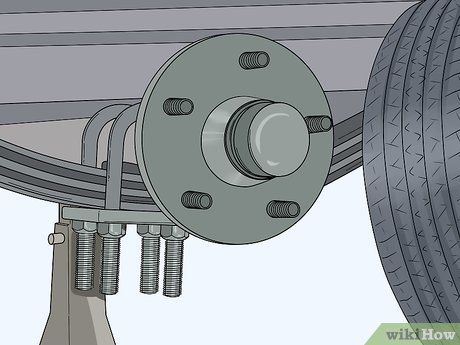

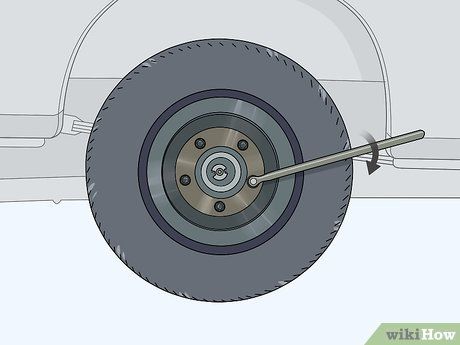

Removing a Wheel and Accessing the Hub Assembly Loosen the lug nuts on all wheels while the trailer is on the ground. Elevate the trailer just enough to lift the wheels. Finish unscrewing the nuts on one wheel, remove them, and slide off the wheel from the hub.

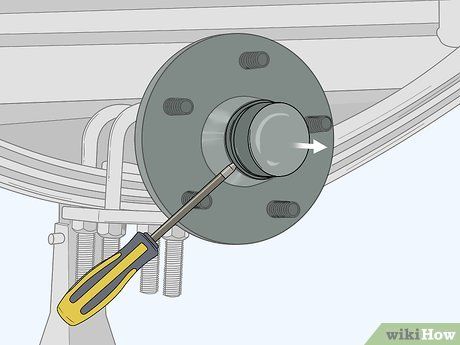

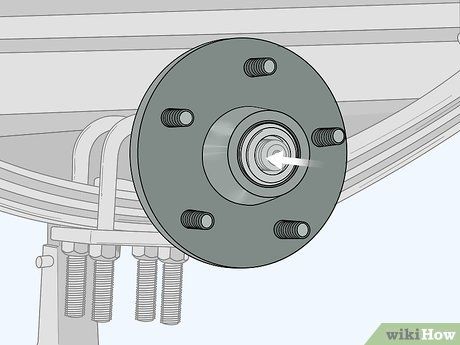

Remove the Dust Cap with Ease Use a flathead screwdriver to gently pry off the dust cap, revealing the hub's inner workings. With a few taps and twists, you'll have it off in no time.

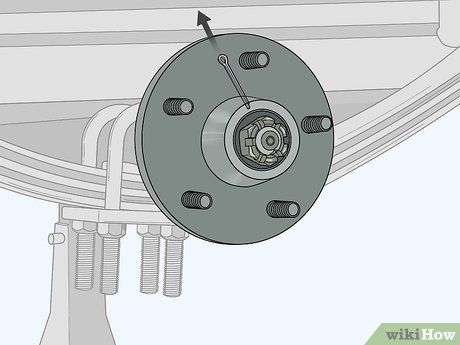

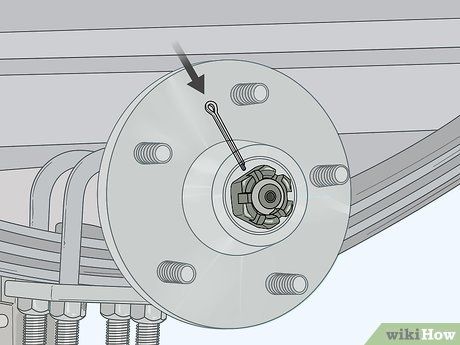

Say Goodbye to the Cotter Pin Straighten and extract the cotter pin effortlessly. This small but vital piece is no match for your steady hands and trusty pliers.

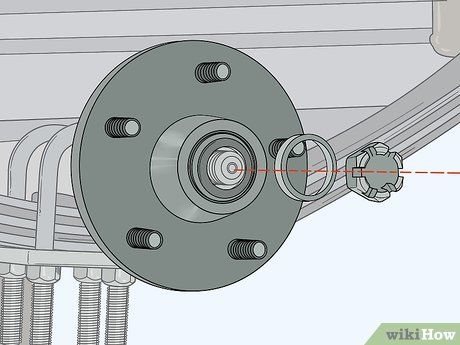

Loosen the Adjusting Nut with Confidence Bid farewell to the adjusting nut and washers. With the right tools and a little finesse, you'll have them off and set aside in no time.

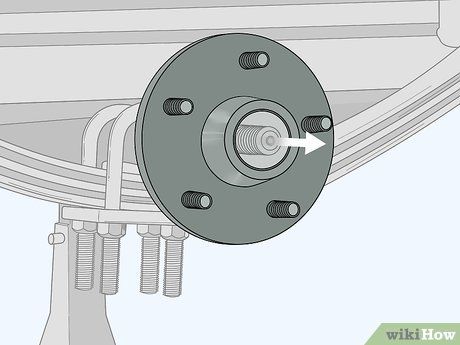

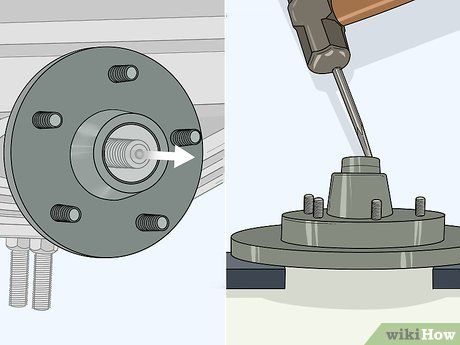

Free the Hub Assembly with Ease Slide the hub assembly off the spindle shaft smoothly onto a flat surface. No need for force, just a gentle pull and it's off.

Retrieve the Outer Bearing with Care Lift the outer bearing out delicately, ensuring its safe removal. Handle with care as you set it aside for the next steps.

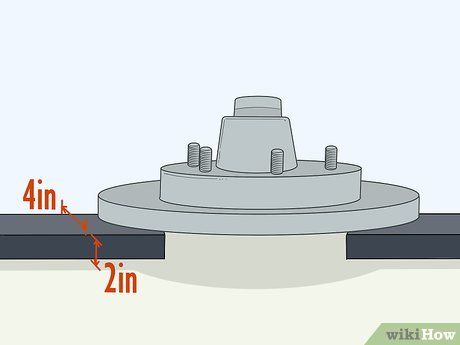

Elevate the Hub with Precision Place the hub assembly on a pair of 2x4s, creating a space beneath the inner bearing. This strategic setup ensures easy removal without damaging the hub.

Pro Tip: Utilize a hollow cinder block or any sturdy object to support the hub assembly with clearance beneath the inner bearing.

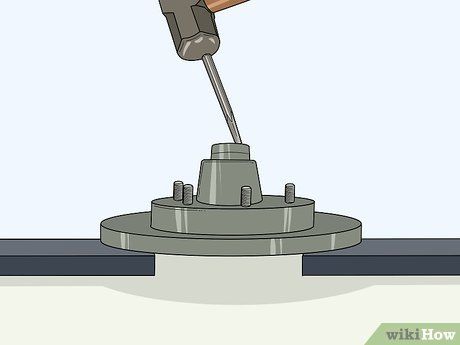

Knock Out the Inner Bearing Gracefully Employ a hammer and punch to delicately tap out the inner bearing. With controlled strikes, ensure a smooth removal process without causing unnecessary damage.

Continue the Wheel Transformation Proceed to remove the remaining wheels one by one, following the same lug nut loosening process. With each hub assembly removed, repeat the bearing removal process for a seamless overhaul.

Installing Fresh Bearings in the Hubs

Cleanse Spindle and Hub Thoroughly Use a rag to wipe away old grease from both the spindle shaft and hub assembly. Ensure a fresh start for your bearings by removing all traces of dirt and grime.

Deep Clean with Kerosene or Solvent Utilize kerosene or solvent-soaked rags to meticulously clean the spindle and hub assembly. Let them soak for optimal results before drying thoroughly.

Apply a Thin Layer of Grease Lightly coat the spindle shaft with new wheel bearing grease, facilitating smoother reassembly and improved heat dissipation.

Pack Bearings with Precision Pack your new bearings with wheel bearing grease, ensuring thorough coverage for optimal performance. Pay attention to the tapered design for proper packing.

Pro Tip: Regular Maintenance Matters

Even if bearings seem fine, annual repacking with fresh grease ensures their longevity and optimal function.

Grease the Hub Thoroughly Apply wheel bearing grease generously inside the hub where the bearings will be seated. Ensure even distribution for optimal performance.

Secure Inner Bearing and Seal Place the inner bearing into the hub followed by the new seal. Gently tap the seal into place to ensure a snug fit, preserving the integrity of the grease seal.

Install the Outer Bearing Insert the outer bearing into the hub, completing the bearing installation process. With this step done, your hubs are ready to be reattached to the trailer.

Reattaching the Hubs to the Trailer

Reattach the Hub Assembly Slide the hub assembly back onto the spindle shaft, ensuring the outer bearing stays in place. With proper lubrication, the hub should slide on smoothly, facilitating easy reattachment.

Caution: Mind the Seal

When sliding the hub onto the spindle, avoid hitting the seal at the back to prevent any potential damage.

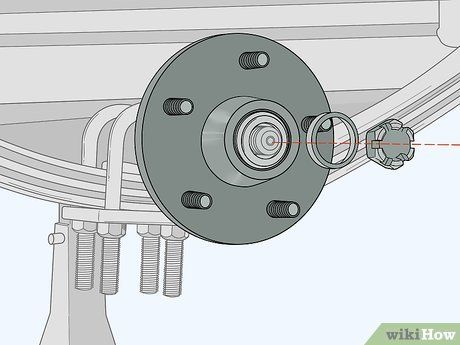

Reinstall the Washer and Adjusting Nut Place the washer over the spindle shaft, covering the outer bearing. Hand tighten the adjusting nut before using an adjustable wrench to secure it. Follow the tightening and loosening sequence for proper adjustment.

Secure with a New Cotter Pin Loosen the nut slightly and insert a new cotter pin into the spindle shaft. Bend it with pliers to lock it securely in place, ensuring no further adjustment is possible.

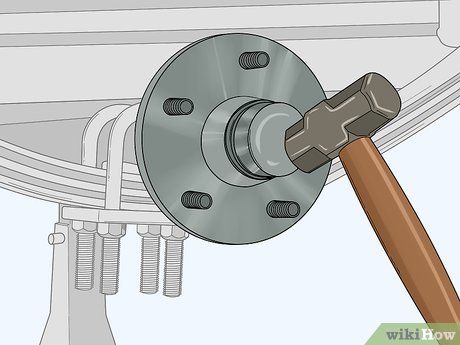

Attach a Fresh Dust Cap Position the dust cap over the adjustment nut and hammer it gently around the perimeter to secure it firmly. Protect your bearings and grease from dust and dirt with this essential cap.

Reconnect the Trailer Wheels Slide the wheels back onto the hubs and tighten the lug nuts with a lug wrench. Lower the trailer to the ground and complete tightening. Your trailer is now ready for a test drive!

Helpful Tips

Essential Tools

Hubs and Bearings Removal

- Jack for lifting

- Lug wrench

- Flathead screwdriver

- Adjustable wrench

- Pliers

- Hammer

- Punch

Installation of New Hubs Bearings

- Rag

- Kerosene or solvent

- Container

- New cotter pins

- New seals

- New dust caps

- New bearings

- Wheel bearing grease

Reattaching Hubs to the Trailer

- Lifting jack

- Lug wrench

- Adjustable wrench

- Pliers

- Hammer