Discover the distinguishing features that set selvedge denim apart from its counterparts.

Key Points to Note

- Selvedge denim is meticulously crafted on shuttle looms, ensuring superior durability and longevity.

- Compared to regular denim, selvedge denim is renowned for its longevity, graceful fading, and comfortable fit.

- To identify selvedge denim, simply roll up the cuff of your jeans to reveal a tidy edge with a distinctive colored thread along the seam.

Essential Actions

Understanding Selvedge Denim

Selvedge denim is characterized by its finished edges. This type of denim is produced using a shuttle loom, which passes a loaded bobbin, known as a shuttle, through parallel threads to create the fabric. The weaving process naturally forms self edges, providing a neat finish.

- The shuttle weaves the lighter weft fabric through the stationary shed of blue fabric, resulting in a denim panel.

Is Selvedge Denim Superior?

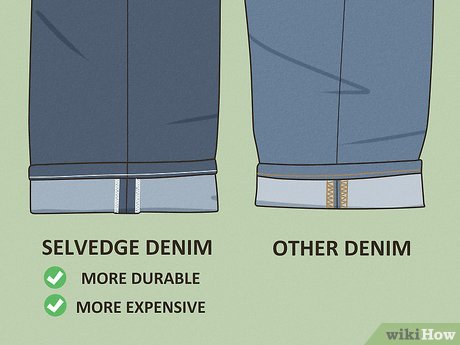

Selvedge denim boasts enhanced durability and a higher price point compared to other denim varieties. Its woven edges contribute to its durability and longevity. Additionally, selvedge denim is acclaimed for its graceful fading and personalized fit over time.

- This meticulous production process yields narrower fabric bolts, rendering selvedge denim more costly than alternatives.

- Contemporary denim production often utilizes projectile looms, which produce one weft thread at a time, resulting in loose threads that are secured after the fabric is woven.

Identifying Selvedge Denim

Identifying Selvedge Denim: Look for a distinctive colored stripe beneath the hem when you turn up the edge of your jeans. This colored stripe, typically red or orange, signifies selvedge denim.

- This colored stripe denotes the finished edge of the fabric—the self edge itself.

The Origins of Selvedge Denim:

Selvedge denim traces back to the earliest days of denim production. Originating in America during the 19th century, denim pioneers like Levi Strauss utilized traditional shuttle looms, resulting in the distinctive selvedge edge we cherish today.

- The Cone Mills Denim, established in 1905 in Greensboro, North Carolina, played a pivotal role in America's denim heritage, hosting numerous denim patents.

The Decline of American Selvedge: As denim demand surged post-WWII, traditional selvedge methods became impractical. American producers shifted to alternative methods, leading to the decline of selvedge denim.

- The closure of Cone Mills denim factory in 2017 marked the end of 112 years of American selvedge production, symbolizing the end of an era.

Revival by Japanese Producers: Despite waning popularity in America, Japanese manufacturers embraced selvedge production. Japan emerged as a major hub for selvedge denim, renowned for its meticulous craftsmanship and unique processes.

- Japanese selvedge, known for its rougher texture and hand-dyed indigo, is produced by esteemed companies like Kurabo, Kuroki, Kaihara, and Toyoshima.

Japanese Preservation of Selvedge: Amidst the decline in American selvedge, Japanese producers upheld its legacy. Japan is now a leading selvedge denim producer, characterized by its attention to detail and quality.

- Japanese selvedge, often hand-dyed with indigo, is thicker and rougher compared to its American counterpart.

- Notable Japanese producers include Kurabo, Kuroki, Kaihara, and Toyoshima.

Distinguishing Selvedge Denim from “Raw” Denim

“Raw” denim refers to unwashed denim straight from the producer. Typically, selvedge denim is raw, meaning it hasn't undergone pre-washing. This enhances its durability and fit, and it develops a unique aging and fading pattern while conforming to your body over time.

- While raw denim can be washed like any other denim, expect it to shrink 1-2 sizes after the initial wash.

Useful Tips

- “Selvedge” is the American spelling, whereas “selvage” is British. Both spellings are acceptable.